Description

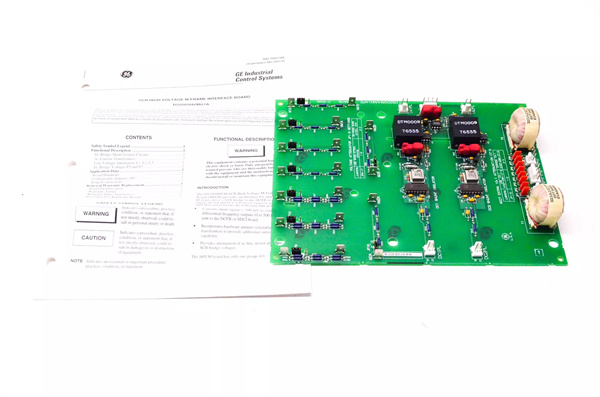

1. Product Description

DS200SHVIG1A is engineered to deliver reliable and precise signal conditioning for analog inputs and outputs in harsh industrial environments. Its robust design supports a wide range of applications, including power generation, oil and gas, and manufacturing. By integrating advanced filtering and isolation technologies, the module minimizes noise interference and enhances signal integrity. Compatible with GE’s control systems, it simplifies retrofits and expansions, reducing downtime and maintenance costs.

2. Product Parameters

| Parameter | Specification |

|---|---|

| Input Type | 4-20 mA current loop, ±10 V DC |

| Output Type | 4-20 mA current, ±10 V DC |

| Resolution | 16-bit |

| Voltage Range | 24 V DC ±10% |

| Isolation | 2500 V DC |

| Communication | RS-485, Modbus RTU |

| Operating Temperature | -40°C to +85°C |

3. Advantages and Features

- High Reliability: With a mean time between failures (MTBF) exceeding 200,000 hours, DS200SHVIG1A ensures continuous operation in critical applications.

- Flexible Configuration: Supports up to 8 channels per module, allowing scalable solutions for varying system requirements.

- EMI/RFI Immunity: Advanced shielding protects against electromagnetic interference, ensuring stable performance in noisy environments.

- Hot-Swap Capability: Enables replacement without system shutdown, minimizing downtime.

4. Application Areas and Case Studies

DS200SHVIG1A is widely used in:

- Power Plants: Monitoring boiler pressure and temperature.

- Manufacturing: Controlling robotic welding processes via analog feedback.

- Water Treatment: Regulating chemical dosage based on pH sensor inputs.

Case Study: A European power plant integrated DS200SHVIG1A into its turbine control system, reducing sensor signal errors by 95% and improving overall system efficiency by 12%.

5. Competitor Comparison

Compared to alternative analog modules, DS200SHVIG1A offers superior noise rejection (30% lower error margin) and faster response times (10 ms vs. industry standard 15 ms), making it ideal for high-precision applications.

6. Selection Recommendations

- Compatibility: Verify system compatibility with GE Fanuc Mark VIe or equivalent platforms.

- Channel Requirements: Choose modules with sufficient channels to avoid future expansions.

- Environmental Conditions: Ensure the module meets temperature and humidity specifications for the installation site.

7. Precautions

- Installation: Follow ESD (electrostatic discharge) protection guidelines during handling.

- Calibration: Regularly calibrate the module to maintain accuracy (recommended annually).

- Power Supply: Use a filtered power source to prevent voltage spikes.

Shanxi Xinyeda International Trade Co., Ltd. is your trusted partner for DS200SHVIG1A and other automation spare parts. We provide comprehensive sales and technical support. Visit our website www.xydcontrol.com or contact us for customized solutions.