Description

Product Overview

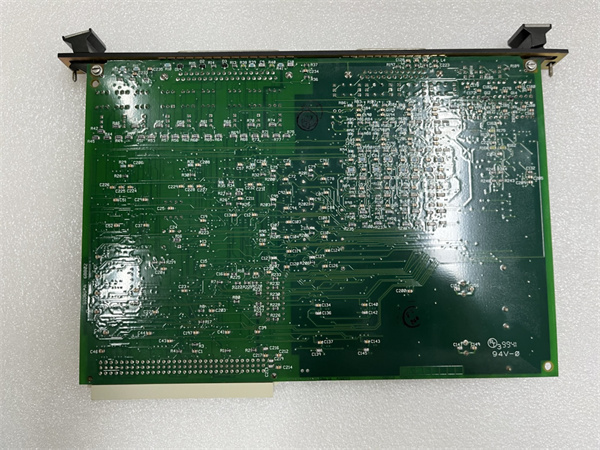

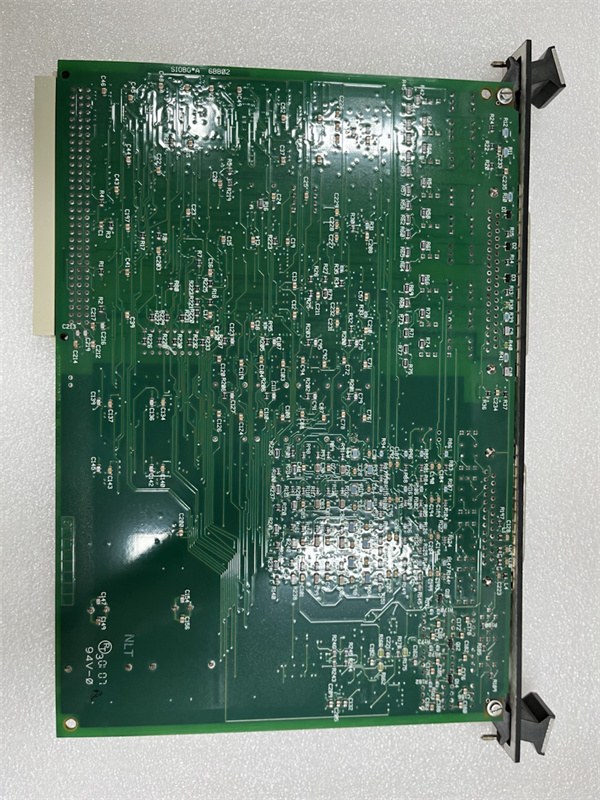

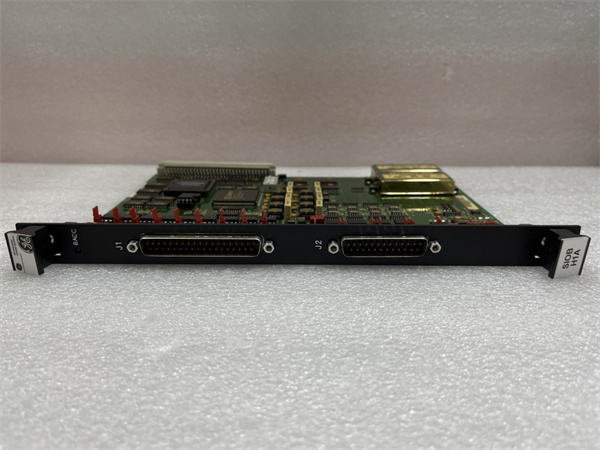

The GE DS200SIOBH1ABA is a critical component in industrial automation systems, functioning as an analog input/output module within the GE Speedtronic Mark VI control system. This module is specifically engineered to interface with a wide array of sensors and actuators, enabling precise measurement and control of vital parameters in gas turbine operations. With its 16 analog input channels and 8 analog output channels, the DS200SIOBH1ABA supports multiple signal types, including voltage, current, and RTD inputs, making it highly versatile for various industrial applications. Its robust design ensures reliable performance in demanding environments, while its integration with the Mark VI system allows for seamless communication and coordination with other control modules. This module plays a pivotal role in maintaining optimal turbine performance, enhancing system efficiency, and ensuring safe and stable operation in power generation and industrial settings.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | DS200SIOBH1ABA |

| Manufacturer | General Electric |

| Product Type | Analog Input/Output Module |

| Series | Speedtronic Mark VI |

| Input Channels | 16 analog inputs |

| Output Channels | 8 analog outputs |

| Input Signal Types | Voltage, current, RTD |

| Output Signal Types | Voltage, current |

| Resolution | 16-bit |

| Sampling Rate | Up to 100 Hz |

| Input Range | ±10 V, ±20 mA, various RTD ranges |

| Output Range | ±10 V, ±20 mA |

| Isolation | 1500 VDC |

| Operating Temperature | -20°C to +70°C |

| Storage Temperature | -40°C to +85°C |

| Humidity | 5% to 95% non-condensing |

| Dimensions | 216 mm x 178 mm x 51 mm |

| Weight | Approximately 1.5 kg |

DS200SIOBH1ABA

Main Features and Advantages

High Channel Density and Versatility

The GE DS200SIOBH1ABA offers a high channel count with 16 analog inputs and 8 analog outputs, providing extensive connectivity for multiple sensors and actuators. Its support for various signal types, including voltage, current, and RTD inputs, allows for seamless integration with diverse industrial equipment. This versatility eliminates the need for multiple specialized modules, reducing system complexity and costs.

Precise Measurement and Control

With a 16-bit resolution and high sampling rate of up to 100 Hz, the module delivers accurate and timely data acquisition and control. This precision is crucial for maintaining optimal turbine performance, ensuring efficient energy conversion, and meeting strict industrial standards. The module’s ability to handle a wide range of input and output signals further enhances its applicability in various industrial processes.

Robust Design for Harsh Environments

The DS200SIOBH1ABA is built to withstand demanding industrial environments, with an operating temperature range of -20°C to +70°C and resistance to humidity, vibration, and electromagnetic interference. Its rugged construction and isolation features ensure reliable operation in challenging conditions, minimizing downtime and maintenance costs.

Seamless Integration with Mark VI System

As part of the GE Speedtronic Mark VI control system, the DS200SIOBH1ABA integrates seamlessly with other modules, enabling efficient communication and coordination. This integration allows for centralized control and monitoring, 简化了系统管理并提高了整体效率. The module’s compatibility with the Mark VI system also ensures long-term support and availability of spare parts.

Application Field

Power Generation

In power plants, the GE DS200SIOBH1ABA is used to monitor and control critical parameters in gas turbines, such as temperature, pressure, and flow rate. By providing accurate and real-time data, the module helps optimize turbine performance, improve efficiency, and ensure safe operation. It is also used in auxiliary systems, such as fuel management and cooling systems, to maintain precise control and monitoring.

Oil and Gas Industry

In the oil and gas sector, the module is employed in various applications, including pipeline monitoring, refinery processes, and offshore platforms. It enables precise measurement and control of parameters such as pressure, temperature, and fluid levels, ensuring safe and efficient operation. The module’s robust design makes it suitable for harsh environments, such as those found in offshore drilling and remote pipeline installations.

Industrial Manufacturing

In industrial manufacturing processes, the DS200SIOBH1ABA is used to control and monitor production equipment, such as motors, pumps, and valves. It provides accurate feedback on process variables, allowing for precise adjustment and optimization of manufacturing processes. The module’s high channel density and versatility make it ideal for complex manufacturing systems that require multiple sensors and actuators.

Chemical and Petrochemical Processes

In chemical and petrochemical plants, the module is used to monitor and control critical processes, such as reactor temperature, pressure, and chemical composition. It ensures precise control of process variables, preventing deviations that could lead to safety hazards or product quality issues. The module’s ability to handle a wide range of input and output signals makes it suitable for diverse chemical and petrochemical applications.

DS200SIOBH1ABA

Related Products

DS200SIOCH1ABA

A similar analog input/output module in the GE Speedtronic Mark VI series, offering different channel configurations and signal types to meet specific application requirements.

DS200TBCCH1A

A terminal block module that provides interface connections for the DS200SIOBH1ABA, facilitating easy installation and wiring of sensors and actuators.

DS200TBCDH1A

Another terminal block module designed for use with the DS200SIOBH1ABA, offering additional interface options and signal conditioning capabilities.

DS200DCCHH1A

A digital control module in the Mark VI series that works in conjunction with the DS200SIOBH1ABA to provide comprehensive control and monitoring of industrial processes.

DS200DCMMH1A

A communication module that enables the DS200SIOBH1ABA to communicate with other components in the control system, such as PLCs, HMIs, and SCADA systems.

Installation and Maintenance

Pre – installation preparation: Before installing the GE DS200SIOBH1ABA, carefully review the installation manual provided by GE. Ensure that the control system is powered off and that all safety procedures are followed. The module should be installed in a clean, dry environment with adequate ventilation. Check the module for any physical damage before installation and verify compatibility with other system components. Use appropriate tools and equipment to install the module securely, following the specified torque values for mounting screws.

Maintenance recommendations: Regular maintenance is essential to ensure the reliable operation of the DS200SIOBH1ABA. Periodically inspect the module for signs of wear, damage, or contamination. Clean the module and its connectors using a soft, dry cloth to remove dust and debris. Check the wiring connections for tightness and integrity, and replace any damaged wires or connectors. Calibrate the module periodically according to the manufacturer’s specifications to maintain accurate measurement and control. If any faults or issues are detected, refer to the troubleshooting guide in the installation manual or contact GE technical support for assistance.

Product Guarantee

GE stands behind the quality and reliability of the GE DS200SIOBH1ABA with a comprehensive product guarantee. The module is backed by GE’s extensive experience and expertise in industrial automation and control systems. GE offers a standard warranty period for the DS200SIOBH1ABA, during which any defects in materials or workmanship will be repaired or replaced at no charge. Additionally, GE provides technical support and training to ensure proper installation, operation, and maintenance of the module. Customers can rely on GE’s global network of service centers and authorized distributors for prompt assistance and access to genuine spare parts. This commitment to quality and customer satisfaction ensures that the DS200SIOBH1ABA delivers long-term performance and value in industrial applications.