Description

Product Overview

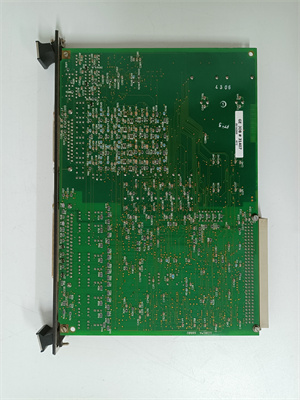

The GE DS200SIOBH1ACA is a sophisticated I/O control board designed by General Electric, belonging to the esteemed Mark VI DS200 series. Engineered to meet the demanding requirements of industrial automation, this board serves as a pivotal interface between various field devices and the control system.

It is crafted to handle a wide range of input and output signals, making it adaptable to diverse industrial applications. Whether it’s receiving signals from sensors that monitor temperature, pressure, or position, or sending control signals to actuators like motors and valves, the DS200SIOBH1ACA ensures seamless data transfer. In industrial setups, it plays a crucial role in coordinating the operation of different components, contributing to the overall efficiency and reliability of the control process. Its design focuses on providing stable and accurate I/O control, making it an essential part of industrial control systems in sectors such as power generation, oil and gas, and manufacturing.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | DS200SIOBH1ACA |

| Manufacturer | General Electric |

| Product Type | I/O Control Board |

| Series | Mark VI DS200 |

| Number of Jumpers | 20 |

| Number of Switches | 18 (3 switch blocks, each with 6 switches) |

| LED Indicator | 1 |

| Connector Type | 1 40 – pin connector |

| Communication Protocols | Likely supports common industrial protocols (not fully specified, but may include Modbus – like protocols for seamless integration with other devices) |

| Operating Temperature Range | Not provided (but typical industrial control boards operate in a range like – 20 °C to + 60 °C to withstand harsh industrial environments) |

| Power Requirements | Not given (designed to be compatible with standard industrial power supply voltages within the Mark VI system) |

| Mounting Method | Not specified (might be suitable for DIN – rail or panel – mount, common in industrial control applications) |

| Input/Output Signal Types | Can handle a variety of digital and potentially some analog signals, considering its role as an I/O control board for industrial applications |

DS200SIOBH1ACA

Main Features and Advantages

Abundant Configuration Options

With 20 jumpers and 18 switches distributed across 3 blocks, the GE DS200SIOBH1ACA offers extensive configuration flexibility. Users can fine – tune its operation to match the specific requirements of their industrial processes. For example, the switches can be used to set different input/output modes, signal polarities, or communication parameters, allowing for customization in various control scenarios.

Reliable Connectivity

Featuring a 40 – pin connector, it ensures a secure and reliable connection to other components in the industrial control system. This connector is designed to withstand the vibrations and harsh conditions often present in industrial environments, minimizing the risk of signal loss or connection failures. Additionally, some of the connectors on the board are capable of synchronizing and connecting via a ribbon cable, further enhancing its connectivity options for different device setups.

Indicator for Quick Status Checks

The single LED light on the DS200SIOBH1ACA serves as a convenient status indicator. It can quickly show the operational status of the board, such as whether it is powered on, receiving input signals correctly, or has any faults. This visual feedback enables operators to quickly assess the board’s condition without the need for complex diagnostic tools, saving time and facilitating prompt troubleshooting.

Application Field

Power Generation

In power plants, the GE DS200SIOBH1ACA is used to interface with numerous sensors and actuators. It can connect to temperature sensors on turbines to monitor the engine’s operating temperature. By accurately processing and transmitting these signals to the central control system, it helps ensure the safe and efficient operation of the turbine. In addition, it can send control signals to valves that regulate the flow of steam or fuel, optimizing the power generation process.

Oil and Gas Industry

Within refineries and oil platforms, this I/O control board plays a vital role. In a refinery, it can be connected to level sensors in storage tanks to monitor the volume of crude oil or refined products. It can also interface with control valves in pipelines, controlling the flow of oil and gas. On an oil platform, it may receive signals from gas leak detectors and send emergency shutdown signals to relevant equipment, enhancing safety in hazardous environments.

Manufacturing

In manufacturing plants, the DS200SIOBH1ACA is used to integrate different parts of the production line. It can connect proximity sensors on conveyor belts to detect the presence of products. Based on these input signals, it can send control commands to motors that drive the conveyor belts, ensuring smooth product flow. In robotic assembly lines, it can interface with limit switches on robotic arms, providing real – time feedback on the arm’s position to the control system for precise movement and accurate assembly operations.

DS200SIOBH1ACA

Related Products

GE DS200SIOBH1ABA

Similar to the DS200SIOBH1ACA, it is also an I/O control board within the Mark VI DS200 series. The main difference might lie in specific configuration options or minor hardware revisions, but both serve the core purpose of providing I/O control in industrial applications.

GE DS200SIOCG1A

Another I/O – related board in the GE product lineup. It could have different input/output capabilities, such as a different number of channels or support for other types of signals. However, it is designed to be used in similar industrial control setups and may be interchangeable in some applications depending on the specific requirements.

GE DS200TBQCG1AAA

This product might be related in terms of its use within the Mark VI system. It could be a module that works in tandem with the DS200SIOBH1ACA, perhaps handling different aspects of the control process, such as signal conditioning or data processing, to complement the I/O control functions of the DS200SIOBH1ACA.

GE DS200SDCIG2AHB

It may be a part of the same family of industrial control components. While its exact function is not clear, it could potentially be used in a related or complementary way to the DS200SIOBH1ACA. For example, it might be involved in data communication or control functions that interact with the I/O operations of the DS200SIOBH1ACA in a larger industrial control network.

GE DS200DPCBG1AAA

This could be another module within the Mark VI series. It may have a different function, like power distribution or digital signal processing, but could be integrated with the DS200SIOBH1ACA in a comprehensive industrial control system. Together, they can contribute to the overall operation and functionality of the industrial automation setup.

Installation and Maintenance

Pre – installation preparation: Before installing the GE DS200SIOBH1ACA, ensure that the power to the relevant industrial control system is switched off to avoid electrical hazards. Thoroughly inspect the board for any visible signs of damage during transit, such as scratches on the circuit board or bent connectors. Familiarize yourself with the installation manual provided by GE, which should include details about the proper mounting method, whether it’s DIN – rail, panel – mount, or another technique. Verify the compatibility of the DS200SIOBH1ACA with other components in the system, including the types of devices it will be connected to and the communication protocols they support. Check the configuration of the jumpers and switches according to your specific application requirements before installation.

Maintenance recommendations: Regularly clean the DS200SIOBH1ACA to remove dust and debris, as these can accumulate over time and affect its performance, especially in terms of heat dissipation. Periodically check the connection status of the 40 – pin connector to ensure it is secure. Monitor the board’s operating temperature, if possible, to ensure it remains within a suitable range. If any abnormal behavior is detected, such as incorrect signal readings or system malfunctions, refer to the troubleshooting guide in the product manual. Keep spare parts, such as replacement jumpers, switches, or connectors, on hand to quickly address any potential failures. Also, periodically review and update the board’s configuration settings if there are any changes in the industrial process it controls.

Product Guarantee

General Electric stands firmly behind the quality of the GE DS200SIOBH1ACA. The product comes with a comprehensive quality assurance program. GE guarantees that the board is free from manufacturing defects for a specified period. In case of any defects during this warranty period, GE will provide repair or replacement services at no additional cost to the customer. Their global network of technical support teams is available around the clock to offer prompt assistance for installation guidance, troubleshooting, and any other technical issues. This reflects GE’s confidence in the reliability and performance of the DS200SIOBH1ACA, ensuring customers can rely on it for their critical industrial applications.