Description

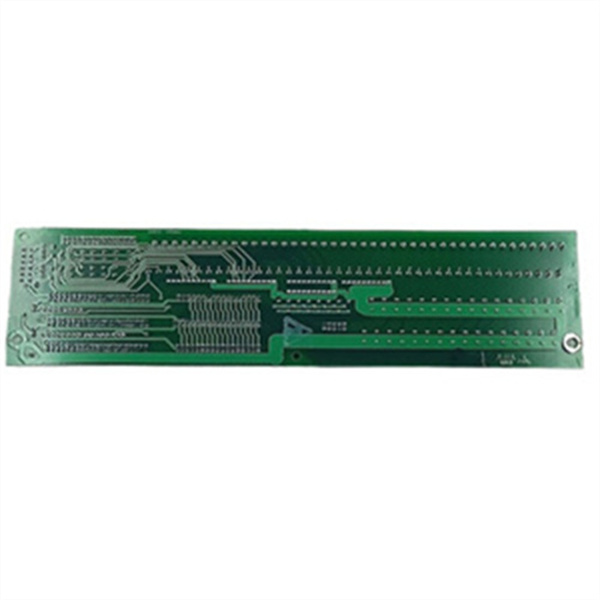

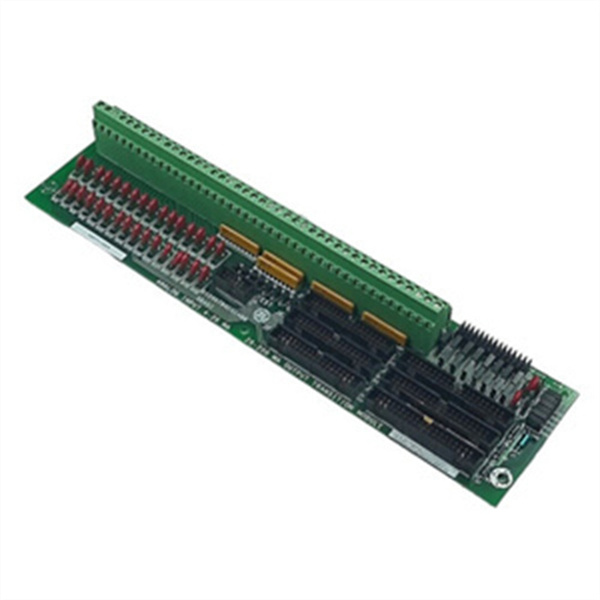

GE Fanuc DS200TBCAG1A Analog I/O Terminal Board for Mark V Turbine Control Systems

The GE Fanuc DS200TBCAG1A is a high-reliability analog I/O terminal board designed for GE’s Mark V series of turbine control systems, specialized in temperature monitoring and signal conditioning for industrial automation. This module is engineered to handle critical applications in power generation, petrochemical, and heavy machinery industries, ensuring precise control and data acquisition under extreme conditions.

1. Product Overview

The DS200TBCAG1A serves as a termination point for analog signals, particularly 3-wire Resistance Temperature Detectors (RTDs), converting raw temperature data into actionable signals for turbine control systems. Its modular design integrates seamlessly into Mark V chassis, supporting up to 30 RTD inputs and providing robust signal isolation and noise filtering. Key features include:

- Dual Connector System: Two 50-pin connectors (JCC and JDD) for direct integration with TCCA boards in the Mark V core, enabling distributed temperature monitoring across 30 channels.

- Industrial-Grade Components: Multilayer PCB with anti-vibration design and conformal coating to withstand harsh environments (e.g., high humidity, electromagnetic interference).

- Safety Compliance: CE, UL, and FCC certifications ensure adherence to global industrial standards.

2. Technical Specifications

| Parameter | Specification |

|---|---|

| Input Type | 3-wire RTD (e.g., PT100, PT500) |

| Channels | 30 isolated inputs |

| Signal Range | 0–20mA, 0–10V (configurable) |

| Accuracy | ±0.1% of full scale |

| Temperature Range | -40°C to +70°C (operating) |

| Power Supply | 24V DC ±10% |

| Dimensions | Standard 19″ rack-mount form factor |

DS200TBCAG1A

3. Key Features

- RTD Termination: Optimized for 3-wire RTDs, compensating for lead wire resistance to ensure accurate temperature measurements in industrial turbines and process plants.

- Redundancy Support: Compatible with GE’s EX2000 series for simplex, dual, or triple-redundant control systems, enhancing reliability in mission-critical applications.

- EMI/RFI Protection: Shielded connectors and noise-filtering circuitry minimize interference in high-electromagnetic environments.

- LED Indicators: Status lights for power, channel activity, and fault conditions simplify troubleshooting.

4. Applications

- Power Generation: Used in gas and steam turbines for real-time temperature monitoring of bearings, exhaust systems, and generator windings.

- Petrochemical Processing: Supports temperature control in reactors, distillation columns, and heat exchangers.

- Heavy Machinery: Integrates with industrial compressors, pumps, and conveyor systems for predictive maintenance.

Case Study: A major U.S. power plant reduced turbine downtime by 25% after deploying DS200TBCAG1A to monitor 30 RTDs in generator windings, detecting overheating 48 hours before critical thresholds.

5. Competitor Comparison

- Higher Channel Density: 30 inputs vs. 16–24 for most alternatives, reducing chassis space by 20–30%.

- RTD-Specific Design: Built-in lead wire compensation eliminates external resistors, unlike generic analog modules.

- Conformal Coating: Enhanced environmental protection compared to standard uncoated boards.

DS200TBCAG1A

6. Selection Recommendations

- RTD-Dominated Systems: Choose DS200TBCAG1A for 3-wire RTD applications over mixed-signal alternatives.

- Space Efficiency: Pair with GE’s DS200TBCAG2A (4-20mA inputs) for hybrid I/O requirements.

- Budget Projects: Use refurbished units from certified vendors for non-critical backups.

7. Installation & Maintenance Notes

- Wiring: Use shielded twisted-pair cables for RTD inputs; torque terminals to 3.5 N·m.

- Calibration: Recommission annually with GE’s Proficy software to maintain accuracy.

- Safety: Handle with anti-static gloves to prevent ESD damage; avoid physical stress on ribbon cables.

Shanxi Xinyeda International Trading Co., Ltd. supplies genuine GE Fanuc DS200TBCAG1A modules with a 12-month warranty, technical support, and global logistics. Visit our website www.xydcontrol.com or contact us for customized solutions.