Description

1. Product Description

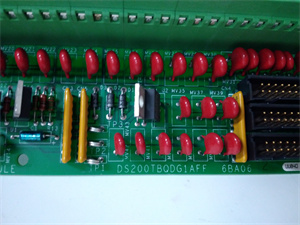

The DS200TBQDG1AFF is an advanced analog termination board crafted by General Electric (GE) for use within its Mark V turbine control systems. This module plays a pivotal role in industrial automation, acting as a crucial interface for handling and conditioning analog signals. It is designed to seamlessly integrate with various sensors and actuators, enabling precise data acquisition and control in complex industrial processes. The DS200TBQDG1AFF is engineered to ensure reliable signal transmission, even in harsh industrial environments characterized by high levels of electrical noise, temperature variations, and mechanical vibrations.

2. Product Parameters

| Parameter | Specification |

|---|---|

| Manufacturer | General Electric (GE) |

| Series | Mark V DS200 |

| Input Signal Types | Proximitor, LVDT, milliamp signals |

| Output Signal Types | Milliamp outputs |

| Terminal Blocks | 2 terminal blocks with 107 signal terminals each |

| Connectors | 3 x 34 – pin connectors |

| Test Points | 3 test points (TP1, TP2, TP3) |

| Jumpers | 2 jumpers (BJ1, BJ2) for field – configurable processing |

| Power Supply | 24V DC |

| Operating Temperature Range | – 40°C to +70°C |

| Dimensions | 170 mm x 90 mm x 5 mm |

| Weight | Approximately 0.15 kg |

3. Advantages and Features

- High – Precision Signal Conditioning: The DS200TBQDG1AFF is equipped with sophisticated voltage – limiting hardware. This feature effectively protects the system from electrical fluctuations, ensuring that the analog signals are accurately processed and transmitted. It can achieve a signal accuracy of up to ±0.1%, which is crucial for applications that demand high – precision control.

- Flexible Configuration: Thanks to the two field – configurable jumpers (BJ1, BJ2), users can easily adapt the board to different system requirements. This flexibility allows for quick and efficient customization without the need for extensive re – engineering, saving both time and cost.

- Robustness and Reliability: With a Mean Time Between Failures (MTBF) exceeding 200,000 hours, the module is highly reliable. It also has a standard PCB coating that provides excellent insulation and heat dissipation properties, enabling it to operate stably in extreme environmental conditions.

- Compact Design: Its compact form factor (170 mm x 90 mm x 5 mm) makes it suitable for installations where space is limited. Despite its small size, it offers a high – density terminal arrangement, allowing for the connection of multiple sensors and actuators.

4. Application Areas and Application Cases

- Power Generation: In gas and steam turbine control systems, the DS200TBQDG1AFF is used to monitor and control various parameters such as temperature, pressure, and vibration. For example, in a large – scale gas power plant, the board is connected to Proximitor sensors to measure the shaft vibration of the turbine. The accurately conditioned signals are then used by the control system to adjust the turbine’s operation in real – time, ensuring safe and efficient power generation.

- Renewable Energy: In wind turbine monitoring and management systems, the module can be used to interface with LVDT sensors to measure blade pitch angles. By precisely processing the sensor signals, the control system can optimize the blade pitch for maximum energy capture, improving the overall efficiency of the wind turbine.

- Industrial Automation: In process control and data acquisition systems, the DS200TBQDG1AFF is used to connect a wide range of sensors and actuators. For instance, in a chemical manufacturing plant, it can be used to monitor the flow rate and chemical composition of various substances in the production process, enabling precise control of the manufacturing process.

5. Competitor Comparison

Compared to similar analog termination boards in the market, the DS200TBQDG1AFF offers several distinct advantages. Firstly, it has a wider operating temperature range (- 40°C to +70°C) compared to many competitors, which typically operate within a narrower temperature range. This makes it more suitable for use in extreme environments. Secondly, its high – precision signal conditioning capabilities with an accuracy of up to ±0.1% are superior to most competing products. Additionally, the flexibility provided by the field – configurable jumpers is a unique selling point, as many competing boards have more rigid configurations.

6. Selection Suggestions

- System Compatibility: Ensure that the DS200TBQDG1AFF is fully compatible with your existing GE Mark V control system. Check the input and output signal types, as well as the communication protocols, to guarantee seamless integration.

- Environmental Conditions: Consider the operating environment where the module will be installed. If the environment is subject to extreme temperatures, high levels of electrical noise, or mechanical vibrations, the DS200TBQDG1AFF‘s robust design makes it an ideal choice.

- Budget: While the DS200TBQDG1AFF offers high – end features and reliability, it is important to compare its cost with your budget. However, also take into account the long – term benefits such as reduced maintenance costs and improved system performance.

7. Precautions

- Installation: When installing the DS200TBQDG1AFF, use appropriate electrostatic discharge (ESD) protection measures to prevent damage to the components. Ensure that all connections are secure and that the board is properly grounded.

- Testing: Use calibrated instruments to verify the functionality of the test points (TP1, TP2, TP3). Regularly perform diagnostic tests to ensure that the module is operating correctly.

- Ribbon Cables: When disconnecting or reconnecting ribbon cables, grasp the connectors firmly to avoid damaging the wires. Do not pull on the cables themselves.

Shanxi Xinyeda International Trade Co., Ltd. is your reliable partner. We provide sales and technical support for DS200TBQDG1AFF and other automation spare parts. Please visit our website www.xydcontrol.com or contact us, and we will be happy to serve you.