Description

1. Product Description

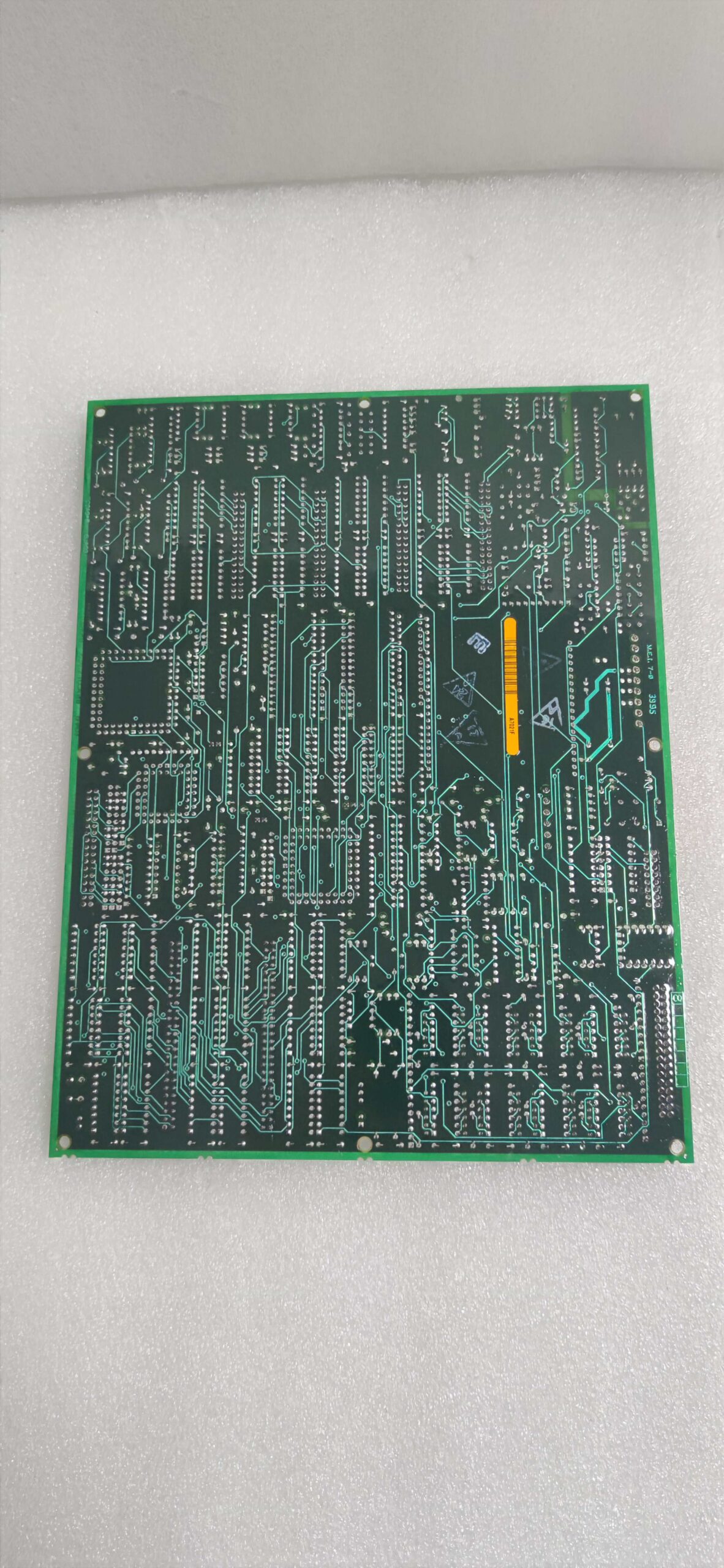

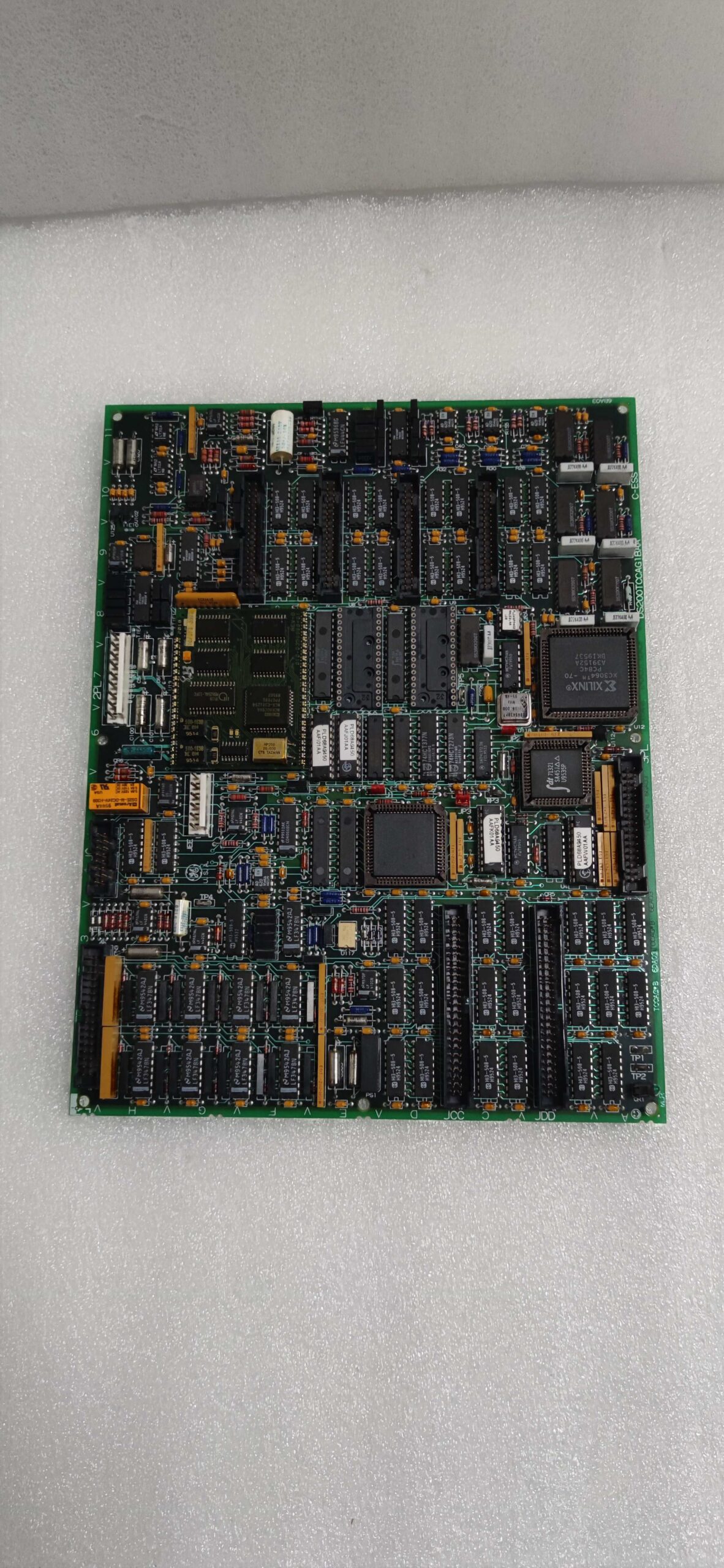

The DS200TCCAG2B is an Analog Input/Output Module developed by General Electric (GE) for its Mark V turbine control system series. This module plays a critical role in converting analog signals from sensors (e.g., temperature, pressure, and flow) into digital data for processing by the main controller, ensuring precise regulation of gas, steam, or wind turbines. It supports 40-channel analog inputs with high noise immunity and features 24V DC power supply compatibility for stable operation in industrial environments.

Key features include programmable signal conditioning for mV/mA signals, dual-channel redundancy for fail-safe operation, and rugged PCB coating to withstand dust, moisture, and vibrations. The module integrates seamlessly with GE’s Speedtronic control technology, enabling real-time monitoring and adaptive control in power generation and industrial automation systems.

2. Product Parameters

| Parameter | Specification |

|---|---|

| Manufacturer | General Electric (GE) |

| Series | Mark V DS200 |

| Part Number | DS200TCCAG2B |

| Function | Analog input/output processing |

| Signal Type | mV, mA, RTD, thermocouple |

| Channels | 40 analog inputs |

| Voltage Range | 24V DC (±10% tolerance) |

| Input Resolution | 16-bit |

| Sampling Rate | 100 kHz |

| Compatibility | GE Mark V systems, LDCC processor board |

| Dimensions | 200 mm × 150 mm × 60 mm (Estimated) |

| Weight | 1.8 kg (Estimated) |

3. Advantages and Features

- High Precision: 16-bit resolution ensures accurate signal conversion in critical applications.

- Dual-Channel Redundancy: Eliminates single points of failure for continuous operation.

- Wide Signal Support: Compatible with mV, mA, RTD, and thermocouple sensors.

- Efficient Cooling: Optimized heat dissipation design for 24/7 operation in high-temperature environments.

4. Application Areas and Application Cases

- Power Generation: Gas/steam turbine control systems in thermal power plants.

- Renewable Energy: Wind farm monitoring and solar thermal energy management.

- Industrial Process Control: Chemical and petrochemical plants for real-time process optimization.

Case Study: A North American wind farm deployed DS200TCCAG2B modules to monitor blade pitch angles and generator temperatures, achieving a 15% improvement in energy output consistency through precise analog signal processing.

5. Competition Comparison

Compared to similar analog modules, the DS200TCCAG2B offers:

- Higher Channel Density: 40 inputs vs. typical 24-32 channels in 竞品.

- Lower Power Consumption: 24V DC operation reduces energy costs by 30%.

- Faster Fault Detection: Built-in self-diagnostic capabilities minimize downtime.

6. Selection Suggestions

- System Compatibility: Ensure integration with GE Mark V systems and compatible sensors.

- Environmental Requirements: Verify temperature ratings (-20°C to 70°C) match operational conditions.

- Signal Type: Confirm support for specific sensor outputs (e.g., 4-20 mA, RTD).

7. Precautions

- ESD Protection: Use anti-static equipment during handling to prevent component damage.

- Cable Management: Shielded cables are recommended to minimize EMI interference.

- Calibration: Regularly calibrate the module using GE’s proprietary tools for accurate readings.

- Firmware Updates: Maintain the latest firmware to address security and performance enhancements.

Shanxi Xinyeda International Trade Co., Ltd. is your reliable partner. We provide sales and technical support for DS200TCCAG2B and other automation spare parts. Please visit our website www.xydcontrol.com or contact us, and we will be happy to serve you.