Description

Product Overview

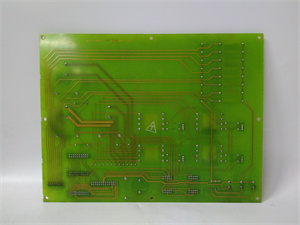

The GE DS200TCEBG1ACE is a protective termination expander board that plays a significant role in industrial control systems, especially within the GE Mark V Speedtronic control system. This board is designed to handle various critical functions, making it an essential component for ensuring the smooth operation and safety of industrial equipment.

It comes equipped with four signal transformers, three bayonet connectors (marked JWX, JWY, and JWZ), one 26 – pin connector, four 10 – pin connectors, and three 20 – pin connectors. These connectors enable seamless integration with other components in the system, facilitating the transfer of signals. Additionally, it houses an audible alarm horn for the Mark V LM system, providing an important alert mechanism in case of any issues. Installed in location 2 of the core system, the GE DS200TCEBG1ACE is engineered to condition potential transformer (PT) and current transformer (CT) signals, contributing to accurate monitoring and control in industrial applications.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | DS200TCEBG1ACE |

| Manufacturer | General Electric |

| Product Type | Protective Termination Expander Board |

| Series | Mark V Speedtronic |

| Input Voltage Range | 12 – 48VDC |

| Output Voltage Range | 5VDC |

| Output Current | Max 10A |

| Efficiency | > 90% |

| Dimensions | 170 mm x 105 mm x 32 mm |

| Weight | Approx. 120 g |

| Operating Temperature | – 20°C to +50°C |

| Storage Temperature | – 40°C to +70°C |

| Environmental Humidity | 5% – 95% relative humidity (non – condensing) |

| Protection Rating | IP20 |

DS200TCEBG1ACE

Main Features and Advantages

Rich Connector Configuration: The GE DS200TCEBG1ACE offers a diverse range of connectors, including bayonet, 26 – pin, 10 – pin, and 20 – pin connectors. This allows for easy connection to multiple devices and systems, enhancing its versatility in industrial setups. For example, the three bayonet connectors (JWX, JWY, and JWZ) can be used to interface with specific components that require this type of connection for signal transfer.

Signal Conditioning Capability: With four signal transformers, the board is well – equipped to condition PT and CT signals. This ensures that the signals are in the appropriate form for accurate processing by other parts of the control system. By providing clean and reliable signals, it helps in improving the overall performance and reliability of the industrial control system.

Alarm Function: The built – in audible alarm horn for the Mark V LM system is a crucial safety feature. In case of abnormal conditions such as system failures or dangerous operating states, the alarm can quickly alert operators, enabling them to take immediate corrective actions. This helps in preventing potential disasters and minimizing downtime in industrial processes.

Signal Conditioning Capability: With four signal transformers, the board is well – equipped to condition PT and CT signals. This ensures that the signals are in the appropriate form for accurate processing by other parts of the control system. By providing clean and reliable signals, it helps in improving the overall performance and reliability of the industrial control system.

Alarm Function: The built – in audible alarm horn for the Mark V LM system is a crucial safety feature. In case of abnormal conditions such as system failures or dangerous operating states, the alarm can quickly alert operators, enabling them to take immediate corrective actions. This helps in preventing potential disasters and minimizing downtime in industrial processes.

Application Field

Power Generation: In power plants, whether they are based on fossil fuels, hydro, or nuclear energy, the GE DS200TCEBG1ACE is used to expand the control system’s capabilities. It can be employed to monitor and control the status of generators, transformers, and switchgear. For instance, it can condition the signals from PTs and CTs associated with generators, providing accurate data for control and protection purposes.

Industrial Automation: Across various industries like manufacturing, food and beverage, and packaging, this board is used to enhance the digital input/output capabilities of automation systems. It enables more precise control over machinery, such as robotic arms in manufacturing plants or filling machines in the food and beverage industry. By expanding the I/O interface, it allows for more complex control logic to be implemented, improving production efficiency and product quality.

Transmission and Distribution: In high – voltage transmission lines and substations, the DS200TCEBG1ACE is utilized to extend the digital quantity interface of the control system. It can monitor the status of transmission lines, such as detecting faults or abnormal voltage levels. This information is then used to trigger protective actions, ensuring the reliable and safe operation of the power grid.

Industrial Automation: Across various industries like manufacturing, food and beverage, and packaging, this board is used to enhance the digital input/output capabilities of automation systems. It enables more precise control over machinery, such as robotic arms in manufacturing plants or filling machines in the food and beverage industry. By expanding the I/O interface, it allows for more complex control logic to be implemented, improving production efficiency and product quality.

Transmission and Distribution: In high – voltage transmission lines and substations, the DS200TCEBG1ACE is utilized to extend the digital quantity interface of the control system. It can monitor the status of transmission lines, such as detecting faults or abnormal voltage levels. This information is then used to trigger protective actions, ensuring the reliable and safe operation of the power grid.

Related Products

GE DS200TCEAG1BTF: This is also an emergency – related board within the GE product line. It is designed to handle specific emergency functions, such as processing turbine overspeed and flame detection trigger signals in the GE Speedtronic MKV gas turbine control system. It may have different input and output requirements compared to the GE DS200TCEBG1ACE, but they both contribute to the overall safety and control of industrial equipment.

GE DS200TCEBG1AAB: While details are scarce, it likely belongs to the same family of boards. It could have similar connector configurations but might be optimized for different applications or have variations in its signal – conditioning capabilities. It may be used in specific industrial scenarios where the GE DS200TCEBG1ACE is not the most suitable option.

GE DS200TCEBG1B: This is a digital signal processor control board. It focuses on processing digital signals, which is different from the GE DS200TCEBG1ACE‘s main function of protective termination expansion. However, in a complex industrial control system, they may work together, with the DS200TCEBG1B processing the digital signals that the DS200TCEBG1ACE helps to condition and transfer.

GE Mark V Speedtronic System Controllers: These controllers are the central units in the Mark V Speedtronic system. The GE DS200TCEBG1ACE works in tandem with them, providing the necessary signal conditioning and expansion functions to support the controllers in effectively managing the industrial process. The controllers send commands based on the signals received through the DS200TCEBG1ACE and other related components.

Potential Transformers (PTs) and Current Transformers (CTs): These are external devices that the GE DS200TCEBG1ACE interfaces with. The board conditions the signals from PTs and CTs, which are crucial for measuring voltage and current in industrial electrical systems. Without proper PTs and CTs, the DS200TCEBG1ACE would not be able to perform its signal – conditioning function effectively.

GE DS200TCEBG1AAB: While details are scarce, it likely belongs to the same family of boards. It could have similar connector configurations but might be optimized for different applications or have variations in its signal – conditioning capabilities. It may be used in specific industrial scenarios where the GE DS200TCEBG1ACE is not the most suitable option.

GE DS200TCEBG1B: This is a digital signal processor control board. It focuses on processing digital signals, which is different from the GE DS200TCEBG1ACE‘s main function of protective termination expansion. However, in a complex industrial control system, they may work together, with the DS200TCEBG1B processing the digital signals that the DS200TCEBG1ACE helps to condition and transfer.

GE Mark V Speedtronic System Controllers: These controllers are the central units in the Mark V Speedtronic system. The GE DS200TCEBG1ACE works in tandem with them, providing the necessary signal conditioning and expansion functions to support the controllers in effectively managing the industrial process. The controllers send commands based on the signals received through the DS200TCEBG1ACE and other related components.

Potential Transformers (PTs) and Current Transformers (CTs): These are external devices that the GE DS200TCEBG1ACE interfaces with. The board conditions the signals from PTs and CTs, which are crucial for measuring voltage and current in industrial electrical systems. Without proper PTs and CTs, the DS200TCEBG1ACE would not be able to perform its signal – conditioning function effectively.

DS200TCEBG1ACE

Installation and Maintenance

Pre – installation preparation: Before installing the GE DS200TCEBG1ACE, ensure that the installation environment meets the specified temperature, humidity, and vibration requirements. Check the integrity of the board for any visible damages during transit. Make a detailed note of all the cables that need to be connected to the board and their corresponding labels. Use an anti – static wrist strap to prevent electrostatic discharge, as this can damage the sensitive electronics on the board. Mount the board in location 2 of the core system as per the system’s guidelines, and carefully connect all the connectors to their respective devices, ensuring a secure and proper connection.

Maintenance recommendations: Regularly inspect the GE DS200TCEBG1ACE for any signs of overheating, such as discoloration of the board or components. Check the connectors for loose connections, as vibrations in industrial environments can cause them to become loose over time. Test the alarm horn periodically to ensure it is functioning correctly. If any issues are detected, refer to the product manual for troubleshooting steps. Replace any faulty components immediately to maintain the optimal performance of the board and the overall industrial control system.

Product Guarantee

General Electric stands firmly behind the quality of the GE DS200TCEBG1ACE. The board undergoes rigorous quality control procedures during manufacturing to meet the highest industry standards. GE offers a comprehensive warranty for a specified period, covering any manufacturing defects. In case of such defects, they will promptly provide repair or replacement services. Their team of highly skilled technical experts is always available to offer technical support for installation, operation, and troubleshooting. This commitment not only reflects GE’s confidence in the product but also gives customers peace of mind, knowing that their investment in the DS200TCEBG1ACE is well – protected and that they can rely on GE for any assistance throughout the product’s lifespan.