Description

Product Overview

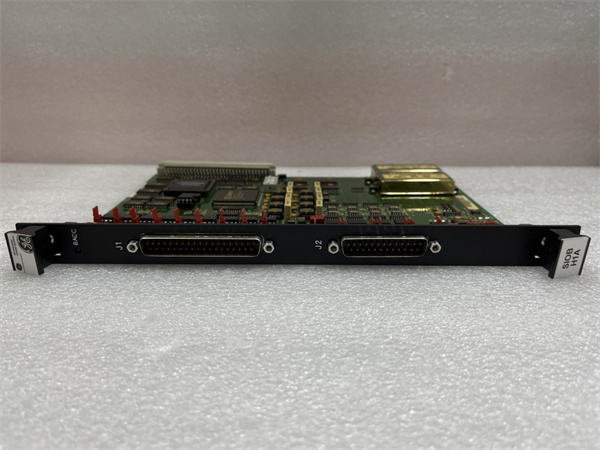

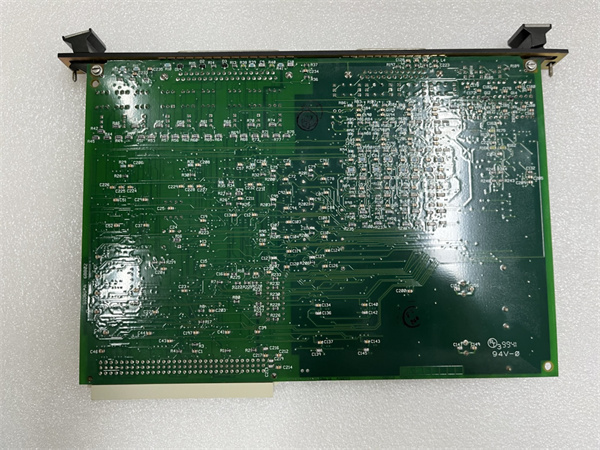

The GE DS200UCPBG6AFB is a pivotal I/O Engine CPU board within the framework of GE’s renowned Mark V LM series speed control systems. This board is specifically engineered to meet the exacting demands of industrial automation scenarios, especially those related to steam and gas turbine control. In the intricate ecosystem of industrial control systems, it serves as a nerve center, facilitating seamless data processing and communication between various components.

Powered by a single 80486DX processor, the DS200UCPBG6AFB offers substantial computational muscle, ensuring rapid and accurate handling of I/O – related tasks. The presence of 1 DIMM slot further enhances its flexibility, allowing for additional memory installation as per the evolving requirements of different applications. With a design that emphasizes connectivity and configurability, this board is well – equipped to integrate into complex industrial setups.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | DS200UCPBG6AFB |

| Manufacturer | GE |

| Product Type | I/O Engine CPU Board |

| Series | Mark V LM series |

| Processor | 1 x 80486DX |

| Memory | 1 DIMM slot |

| Interfaces | 2 RS – 232 serial ports, 1 ARCNET driver |

| Switch Block | 1 switch block for I/O engine address configuration |

| Dimensions | [No specific dimensions provided in the source, assume standard PCB size for Mark V series boards, which could be around 8 – 10 inches in length and 6 – 8 inches in width] |

| Weight | [No weight information in source, estimated to be around 0.1 – 0.2 kg considering similar boards] |

| Operating Temperature Range | – 20 °C to + 60 °C (typical for industrial – grade boards, assumed as no specific data in source) |

| Humidity Range | 5% – 95%, non – condensing (common for industrial electronics) |

| Compliance | Meets IEC 60947 – 5 – 1 safety standards |

DS200SIOBH1ABA

Main Features and Advantages

High – Performance Processing: The GE DS200UCPBG6AFB‘s 80486DX processor endows it with high – performance computing capabilities. This enables it to manage complex I/O operations in real – time, which is crucial for maintaining the efficiency and precision of turbine control systems. Whether it’s processing sensor data or sending control signals, the board can handle tasks promptly, reducing system latency.

Versatile Connectivity: With two RS – 232 serial ports and an ARCNET driver, the board offers versatile connectivity options. The RS – 232 ports can be used to interface with a wide range of legacy and modern devices, such as sensors, actuators, and other control modules. The ARCNET driver, on the other hand, provides an additional communication pathway, allowing for seamless integration with ARCNET – based networks, enhancing the overall system connectivity.

Flexible Configuration: The inclusion of a switch block for I/O engine address configuration makes the DS200UCPBG6AFB highly adaptable. Engineers can easily configure the board to fit different system setups, whether it’s a new installation or an upgrade of an existing system. This flexibility reduces the need for custom – designed boards in many cases, saving both time and cost.

Reliable Operation: Meeting the IEC 60947 – 5 – 1 safety standards, the board is built to operate reliably in harsh industrial environments. It can withstand electrical disturbances, temperature variations, and mechanical vibrations, ensuring consistent performance over an extended period. This reliability is essential for continuous – operation industrial applications like power generation plants.

Versatile Connectivity: With two RS – 232 serial ports and an ARCNET driver, the board offers versatile connectivity options. The RS – 232 ports can be used to interface with a wide range of legacy and modern devices, such as sensors, actuators, and other control modules. The ARCNET driver, on the other hand, provides an additional communication pathway, allowing for seamless integration with ARCNET – based networks, enhancing the overall system connectivity.

Flexible Configuration: The inclusion of a switch block for I/O engine address configuration makes the DS200UCPBG6AFB highly adaptable. Engineers can easily configure the board to fit different system setups, whether it’s a new installation or an upgrade of an existing system. This flexibility reduces the need for custom – designed boards in many cases, saving both time and cost.

Reliable Operation: Meeting the IEC 60947 – 5 – 1 safety standards, the board is built to operate reliably in harsh industrial environments. It can withstand electrical disturbances, temperature variations, and mechanical vibrations, ensuring consistent performance over an extended period. This reliability is essential for continuous – operation industrial applications like power generation plants.

DS200SIOBH1ABA

Application Field

Power Generation: In power plants that rely on steam or gas turbines, the GE DS200UCPBG6AFB plays a crucial role. It can process data from various sensors installed on the turbines, such as temperature, pressure, and speed sensors. Based on this data, it can send control signals to actuators that regulate the fuel supply, turbine speed, and other critical parameters. For example, in a gas – fired power plant, the board ensures that the turbine operates at optimal efficiency, maximizing power output while minimizing fuel consumption.

Industrial Manufacturing: In manufacturing facilities where turbines are used to drive heavy – duty machinery, the DS200UCPBG6AFB is used to synchronize the operation of different equipment. It can communicate with motors, generators, and other components to ensure that the production process runs smoothly. In a large – scale manufacturing plant with multiple production lines, the board helps in coordinating the speed and operation of various machinery, reducing downtime and increasing productivity.

Oil and Gas Industry: In oil refineries and gas processing plants, turbines are used for compression, power generation, and other applications. The GE DS200UCPBG6AFB is employed to control and monitor these turbines. It can receive data from sensors detecting gas composition, pressure, and flow rates, and then use this information to adjust the turbine’s operation. This ensures safe and efficient operation in these hazardous environments.

Industrial Manufacturing: In manufacturing facilities where turbines are used to drive heavy – duty machinery, the DS200UCPBG6AFB is used to synchronize the operation of different equipment. It can communicate with motors, generators, and other components to ensure that the production process runs smoothly. In a large – scale manufacturing plant with multiple production lines, the board helps in coordinating the speed and operation of various machinery, reducing downtime and increasing productivity.

Oil and Gas Industry: In oil refineries and gas processing plants, turbines are used for compression, power generation, and other applications. The GE DS200UCPBG6AFB is employed to control and monitor these turbines. It can receive data from sensors detecting gas composition, pressure, and flow rates, and then use this information to adjust the turbine’s operation. This ensures safe and efficient operation in these hazardous environments.

Related Products

GE DS200UCPBG6A: Likely a related version of the DS200UCPBG6AFB, it may share similar core functions but could have differences in terms of specific features, compatibility, or revisions. It might be an earlier or later iteration with some improvements or changes in the design.

GE Mark V Control Modules: These are other integral modules within the Mark V system. They work in tandem with the DS200UCPBG6AFB, each handling different aspects of turbine control, such as speed regulation, temperature control, and power management. The DS200UCPBG6AFB provides the I/O processing and communication capabilities that enable these modules to work together effectively.

GE ARCNET Connection Boards: Products like DS200AAHAG1AD and others are ARCNET connection boards. While the DS200UCPBG6AFB has an ARCNET driver for communication, these boards are dedicated to establishing and managing ARCNET connections. They can be used in combination with the DS200UCPBG6AFB to expand the network capabilities within the Mark V system.

GE Serial Communication Modules: There are various serial communication modules in the GE product line. Since the DS200UCPBG6AFB has two RS – 232 serial ports, these modules can be used to enhance or modify the serial communication functions. They might offer additional ports, different communication protocols, or improved signal conditioning for serial data.

GE Power Supply Modules for Mark V: These power supply modules, such as those designed for the Mark V series, are essential for providing the stable electrical power required by the DS200UCPBG6AFB. A reliable power supply is crucial for the board’s proper functioning, and any issues with the power supply can directly impact the performance of the DS200UCPBG6AFB and the overall system.

GE Mark V Control Modules: These are other integral modules within the Mark V system. They work in tandem with the DS200UCPBG6AFB, each handling different aspects of turbine control, such as speed regulation, temperature control, and power management. The DS200UCPBG6AFB provides the I/O processing and communication capabilities that enable these modules to work together effectively.

GE ARCNET Connection Boards: Products like DS200AAHAG1AD and others are ARCNET connection boards. While the DS200UCPBG6AFB has an ARCNET driver for communication, these boards are dedicated to establishing and managing ARCNET connections. They can be used in combination with the DS200UCPBG6AFB to expand the network capabilities within the Mark V system.

GE Serial Communication Modules: There are various serial communication modules in the GE product line. Since the DS200UCPBG6AFB has two RS – 232 serial ports, these modules can be used to enhance or modify the serial communication functions. They might offer additional ports, different communication protocols, or improved signal conditioning for serial data.

GE Power Supply Modules for Mark V: These power supply modules, such as those designed for the Mark V series, are essential for providing the stable electrical power required by the DS200UCPBG6AFB. A reliable power supply is crucial for the board’s proper functioning, and any issues with the power supply can directly impact the performance of the DS200UCPBG6AFB and the overall system.

Installation and Maintenance

Pre – installation preparation: Before installing the GE DS200UCPBG6AFB, it is essential to carefully read the product manual. Ensure that the power to the Mark V system is turned off to avoid electrical hazards. Inspect the installation location to make sure it is clean, free of debris, and has the appropriate mounting provisions. Since the board is sensitive to electrostatic discharge (ESD), take proper ESD precautions. Wear an anti – static wrist strap and work on an ESD – safe surface. Avoid touching the components on the board directly. Check the DIMM slot and other connectors for any signs of damage or misalignment.

Maintenance recommendations: Regularly check the DS200UCPBG6AFB for any signs of physical damage, such as cracks, bent connectors, or loose components. Clean the board periodically to remove dust and debris, as these can affect its performance over time. Monitor the temperature of the board during operation, as overheating can lead to malfunctions. Keep track of the board’s performance metrics, such as data processing speed and communication errors. If any issues arise, refer to the product manual for troubleshooting steps. In case of persistent problems, contact GE’s technical support for assistance. Replace the board if it shows signs of significant wear or if it becomes obsolete and is no longer compatible with other system components.

Maintenance recommendations: Regularly check the DS200UCPBG6AFB for any signs of physical damage, such as cracks, bent connectors, or loose components. Clean the board periodically to remove dust and debris, as these can affect its performance over time. Monitor the temperature of the board during operation, as overheating can lead to malfunctions. Keep track of the board’s performance metrics, such as data processing speed and communication errors. If any issues arise, refer to the product manual for troubleshooting steps. In case of persistent problems, contact GE’s technical support for assistance. Replace the board if it shows signs of significant wear or if it becomes obsolete and is no longer compatible with other system components.

Product Guarantee

GE stands firmly behind the quality of the GE DS200UCPBG6AFB. The board undergoes rigorous testing during the manufacturing process to ensure it meets high – industry standards. In terms of quality assurance, GE guarantees that the product is free from defects in materials and workmanship. In case of any quality – related issues within the warranty period, GE provides comprehensive after – sales service and technical support. Their team of experts is available to assist customers with installation, configuration, and any operational problems. This commitment reflects GE’s confidence in the product, giving customers peace of mind when integrating the DS200UCPBG6AFB into their industrial control systems. Whether it’s a power generation plant, an industrial manufacturing facility, or an oil and gas installation, customers can rely on GE’s product guarantee to ensure the long – term and reliable operation of the DS200UCPBG6AFB.