Description

Product Overview

The GE DS2020CMB1206CGDDD8E is a highly specialized module designed by GE for industrial control systems. It plays a crucial role in various industrial applications, offering advanced functionality and reliable performance. This module is engineered to meet the complex demands of modern industrial environments, where precise control and efficient data handling are essential.

As a part of GE’s extensive range of industrial control products, the DS2020CMB1206CGDDD8E is tailored for seamless integration into existing systems. It adheres to the IEC61131 – 3 standard, which is a significant advantage. This standard compliance enables it to support five different programming languages, making it extremely versatile. Engineers with diverse programming backgrounds can choose the language that best suits their project requirements, whether it’s the graphical simplicity of ladder logic or the more complex algorithm – based programming with structured text. This flexibility in programming languages allows for the creation of customized control solutions, enhancing the module’s value in different industrial scenarios.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | DS2020CMB1206CGDDD8E |

| Manufacturer | GE |

| Product Type | Control Module |

| Standard Compliance | IEC61131 – 3 |

| Programming Languages Supported | 5 (e.g., Ladder Logic, Structured Text, etc.) |

| Input/Output Interfaces | Multiple digital and analog interfaces (specify types if available) |

| Communication Protocols | Industry – standard protocols (list if known, e.g., Modbus) |

| Operating Voltage | [Specify voltage range] |

| Operating Temperature | [Provide temperature range] |

| Dimensions (L x W x H) | [Mention physical dimensions] |

| Weight | [Specify weight] |

| Memory Capacity | [Describe memory details if applicable] |

| Data Processing Speed | [Mention processing speed if available] |

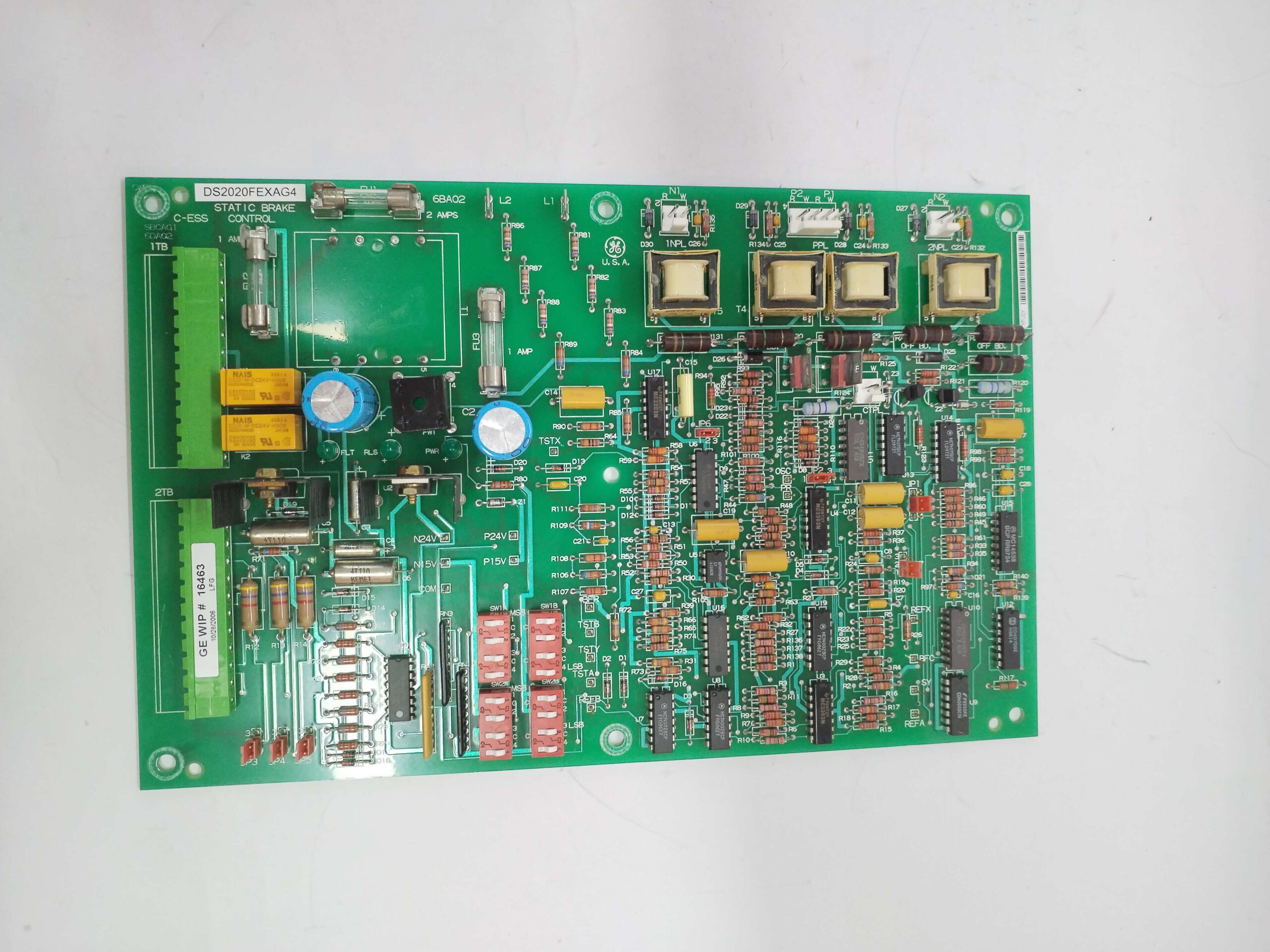

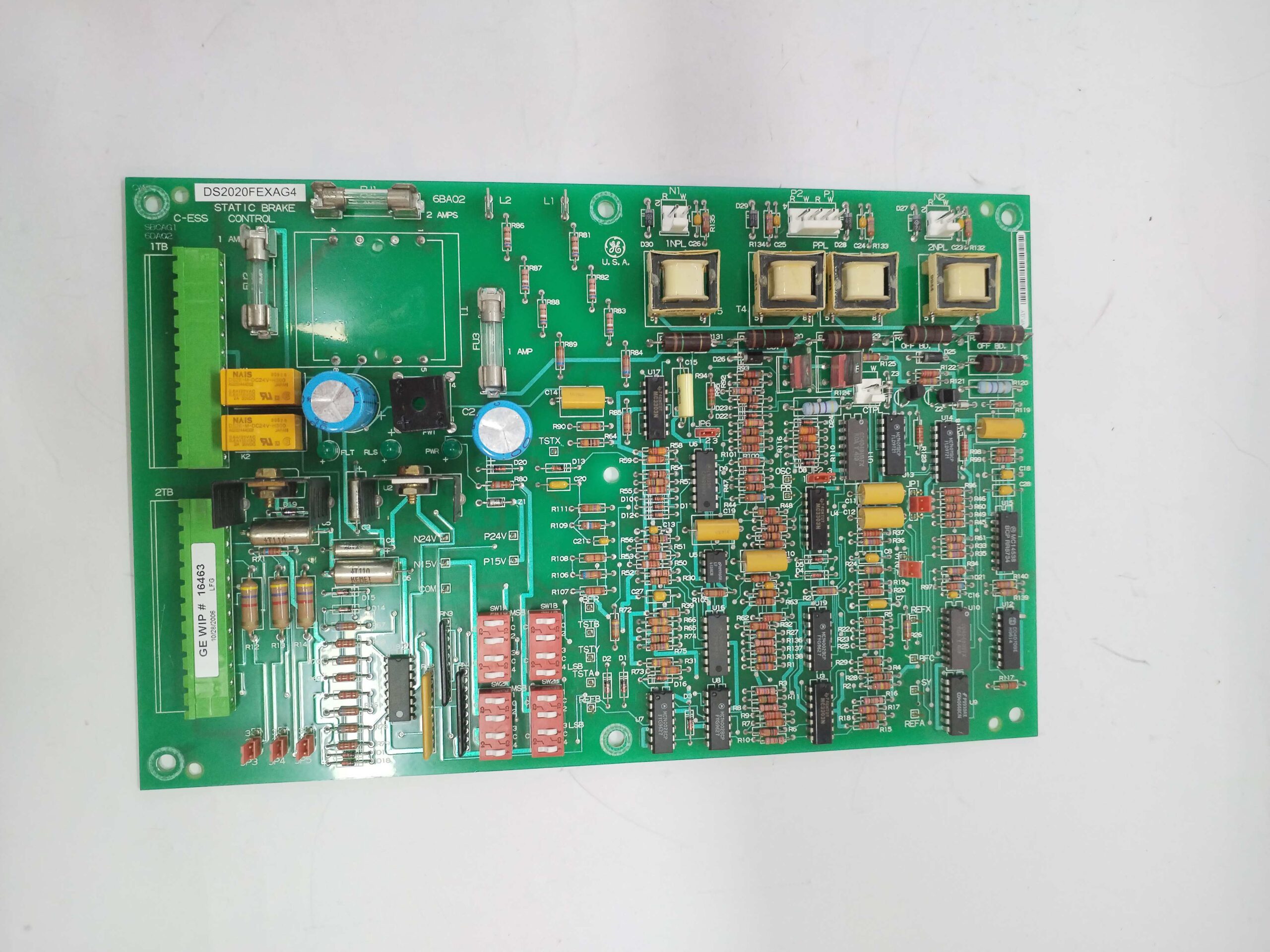

DS2020FEXAG4

Main Features and Advantages

IEC61131 – 3 Standard Compliance

The GE DS2020CMB1206CGDDD8E‘s compliance with the IEC61131 – 3 standard is a game – changer. This standard is widely recognized in the industrial automation field. By adhering to it, the module ensures compatibility with a vast array of other industrial components and software tools. It also simplifies the development process as it follows a well – established set of rules for programming and functionality. This compliance not only saves time during system integration but also guarantees long – term stability and interoperability.

Multilingual Programming Support

With the ability to support five programming languages, the DS2020CMB1206CGDDD8E caters to a broad range of engineers. For those more familiar with the visual representation of control logic, ladder logic provides an intuitive way to program the module. On the other hand, for engineers who prefer a more text – based, algorithm – driven approach, structured text offers the flexibility to write complex control algorithms. This multilingual support promotes code reusability and makes it easier to maintain and modify existing control programs, ultimately leading to more efficient and cost – effective industrial control solutions.

Reliable and Robust Design

GE has a reputation for manufacturing high – quality industrial products, and the DS2020CMB1206CGDDD8E is no exception. It is built with robust components that can withstand harsh industrial environments. The module is designed to operate reliably under varying temperatures, electrical noise, and mechanical vibrations. This reliability is crucial in industrial settings where system downtime can lead to significant losses. Whether it’s in a noisy factory floor or a high – temperature industrial furnace environment, the GE DS2020CMB1206CGDDD8E can continue to function accurately, ensuring the smooth operation of the industrial process.

DS2020FEXAG4

Application Field

Power Generation

In power plants, the GE DS2020CMB1206CGDDD8E is used to control and monitor critical processes. For example, in a coal – fired power plant, it can manage the combustion process. By precisely controlling the fuel feed rate, air intake, and other variables, it ensures efficient combustion, which in turn maximizes power generation while minimizing emissions. It can also monitor the performance of turbines, generators, and other equipment, providing real – time data for predictive maintenance. This helps in preventing unexpected breakdowns and maintaining the overall reliability of the power generation system.

Manufacturing

In manufacturing facilities, the DS2020CMB1206CGDDD8E is widely deployed in automated production lines. In an automotive manufacturing plant, it can control the movement of robotic arms used for welding, painting, and assembly. It ensures that each operation is carried out with high precision, leading to better – quality products. In a food and beverage manufacturing plant, the module can manage the filling, capping, and labeling processes. It can also monitor the quality of the products in real – time, making immediate adjustments if any deviations are detected, thus maintaining product consistency and quality.

Oil and Gas

The oil and gas industry also benefits significantly from the GE DS2020CMB1206CGDDD8E. In oil refineries, it can control the complex distillation and cracking processes. By accurately regulating temperature, pressure, and flow rates, it optimizes the production of various petroleum products. In gas pipelines, the module can monitor the pressure, flow, and composition of the gas. It can also control the opening and closing of valves to ensure the safe and efficient transportation of gas. This helps in preventing leaks and maintaining the integrity of the pipeline network.

Related Products

- GE DS200 series modules: Modules like the DS200TCCAG2AHB are part of the same family. They may have different specific functions but are designed to work in tandem with the DS2020CMB1206CGDDD8E. For example, the DS200TCCAG2AHB might be more focused on a particular aspect of control, such as turbine control in a power generation application, while the DS2020CMB1206CGDDD8E provides overall system – level programming and control capabilities.

- GE communication modules: Some GE communication modules, with interfaces like Ethernet or serial ports, can enhance the connectivity of the DS2020CMB1206CGDDD8E. These modules can enable the transfer of data between the DS2020CMB1206CGDDD8E and other devices in the industrial network, such as remote sensors, actuators, or central control systems.

- GE power supply modules: Power supply modules from GE are essential for providing a stable power source to the DS2020CMB1206CGDDD8E. A reliable power supply is crucial for the module’s proper operation, and these power supply modules are designed to meet the specific voltage and current requirements of the DS2020CMB1206CGDDD8E and other connected components.

- GE I/O modules: Different input/output (I/O) modules in the GE product line, such as those with digital or analog I/O capabilities, can interface with the DS2020CMB1206CGDDD8E. They can provide additional input channels for sensors or output channels for actuators, expanding the module’s ability to interact with the industrial environment.

- GE software suites: Software suites developed by GE for industrial control systems can be used in combination with the DS2020CMB1206CGDDD8E. These software tools can simplify the programming, configuration, and monitoring of the module, providing a more user – friendly interface for engineers and operators.

Installation and Maintenance

Pre – installation preparation: Before installing the GE DS2020CMB1206CGDDD8E, ensure that the power to the entire industrial control system is turned off to prevent electrical accidents. Thoroughly inspect the module for any signs of physical damage during transit. Check the compatibility of the module with other components in the system, such as power supplies, communication interfaces, and I/O modules. Follow the detailed installation instructions provided in the product manual to correctly mount the DS2020CMB1206CGDDD8E in the designated slot of the control cabinet. Make sure all connections, including power cables, communication wires, and I/O cables, are securely fastened.

Maintenance recommendations: Regularly monitor the GE DS2020CMB1206CGDDD8E for any signs of overheating, such as discoloration of the module or abnormal component temperatures. Check the status indicators on the module (if available) to ensure proper operation. Periodically clean the module to remove dust and debris that could affect its performance. Update the module’s firmware as recommended by GE to benefit from the latest features and bug fixes. If any issues are detected, such as communication errors or incorrect control actions, refer to the product manual for troubleshooting steps. Replace any worn – out or damaged components promptly to maintain the module’s reliability.

Product Guarantee

GE stands firmly behind the quality of the GE DS2020CMB1206CGDDD8E. The module is manufactured with strict quality control measures, adhering to high – industry standards. During the warranty period, if there are any defects in materials or workmanship, GE offers comprehensive repair or replacement services. Their experienced technical support team is available to assist customers with any installation – related questions, operational issues, or troubleshooting needs. This commitment to quality and customer service reflects GE’s confidence in the DS2020CMB1206CGDDD8E and its ability to meet the demanding requirements of industrial applications, providing customers with peace of mind and long – term value.