Description

Product Overview

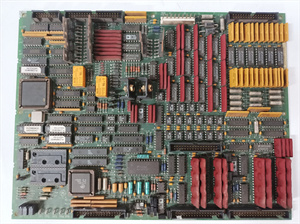

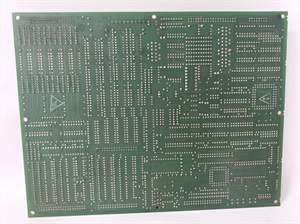

The GE DS215TCQAG1BZZ01A is a circuit board hailing from General Electric, a company with a long – standing reputation in industrial automation and power management. This board is part of the Mark V series, which has been widely utilized in various industrial control applications, especially in turbine control systems.

Within the Mark V series ecosystem, the GE DS215TCQAG1BZZ01A plays a crucial role in handling input and output operations. It interfaces with multiple sensors and actuators, collecting data from the field and transmitting control signals. For instance, in a gas turbine control setup, it can receive temperature and pressure sensor readings. Based on the programmed logic, it then sends appropriate control commands to adjust the fuel supply or the position of valves. This board’s functionality is integral to ensuring the stable and efficient operation of the turbine, making it a key component for maintaining optimal performance in power generation and industrial processes that rely on turbine – driven machinery.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | DS215TCQAG1BZZ01A |

| Manufacturer | GE |

| Product Type | Circuit Board |

| Series | Mark V |

| Function | Input/Output Handling in Turbine Control Systems |

| Mounting Method | Suitable for standard industrial rack or cabinet mounting |

| Operating Temperature | Typically designed for normal industrial ambient temperatures (details may vary, but around 0 – 50°C) |

| Communication Interface | Connects to other components in the Mark V system for data transfer |

| Firmware | Equipped with specific firmware for its operation within the Mark V series |

| PCB Coating | Normal coating to protect against dust and minor environmental factors |

| Artwork Revision | Z (as indicated in the model number) |

DS215TCQAG1BZZ01A

Main Features and Advantages

Reliable in Turbine – Centric Applications

The GE DS215TCQAG1BZZ01A is engineered to be highly reliable in turbine control environments. Its design has been optimized over time to withstand the rigors of continuous operation in power – intensive settings. In power plants, where turbines run for extended periods, this board can consistently perform its input/output functions without significant degradation. It helps maintain the integrity of the control system, ensuring that turbines operate within safe and efficient parameters.

Seamless Integration within Mark V Series

As a part of the Mark V series, it has seamless integration capabilities. It can communicate effectively with other boards and components within the same series. This allows for a cohesive and coordinated control system. For example, it can quickly exchange data with other I/O boards and the central controller in the Mark V setup. This integration reduces the complexity of system design and implementation, as all components are designed to work in harmony, enhancing the overall performance of the turbine control system.

Proven Track Record

The Mark V series, including the DS215TCQAG1BZZ01A, has a long – established track record in the industry. Over the years, it has been deployed in thousands of installations worldwide. This widespread use is a testament to its effectiveness and durability. Operators and engineers trust this board for their turbine control needs, knowing that it has been tested in various real – world scenarios and has consistently delivered reliable performance.

Application Field

Power Generation

In power plants, whether they are gas – fired, coal – fired, or even some types of renewable energy power plants that use turbines, the GE DS215TCQAG1BZZ01A is extensively used. In a gas – turbine – based power plant, it can be used to monitor and control the critical parameters of the turbine. It receives data from sensors that measure the temperature of the combustion gases, the pressure of the air intake, and the rotational speed of the turbine shaft. Based on this data, it controls actuators that adjust the fuel injection rate and the angle of the turbine blades. This ensures efficient power generation, minimizes fuel consumption, and helps maintain the stability of the electrical grid.

Industrial Manufacturing

Industries that rely on turbine – driven machinery for their manufacturing processes also benefit from the DS215TCQAG1BZZ01A. For example, in large – scale chemical plants, turbines are used to drive compressors that are crucial for various chemical reactions. The board can be used to control the operation of these turbines, ensuring that the compressors maintain the required pressure levels. In paper mills, where turbines power the large – scale paper – making machines, the board helps in monitoring and controlling the speed and performance of the turbines, ensuring a consistent and high – quality paper – making process.

DS215TCQAG1BZZ01A

Related Products

- GE DS215TCCBG1BZZ01A: Another board in the Mark V series, it is a common extended analog I/O board. While the DS215TCQAG1BZZ01A focuses on general input/output handling in turbine control, the DS215TCCBG1BZZ01A is more specialized in analog I/O functions, such as handling RTDs and milliamp inputs.

- GE DS200TCQAG1A: Also related to analog input/output in the Mark V setup. It may have different input/output channel configurations or slightly different firmware functionality compared to the DS215TCQAG1BZZ01A, catering to different application requirements within the turbine control systems.

- GE DS200TCQCG1BJF: A processor card in the series. It works in tandem with the DS215TCQAG1BZZ01A, with the processor card handling the data processing tasks based on the input received by the DS215TCQAG1BZZ01A board.

- GE DS200TCPSG1APE: A power supply board for the Mark V system. It provides the necessary power to components like the DS215TCQAG1BZZ01A, ensuring stable operation of the entire control system.

- GE DS200TBCAG1AAB: A transition module in the Mark V series. It can be used to interface between different parts of the control system where the DS215TCQAG1BZZ01A is also a part, enabling smooth communication and data transfer.

Installation and Maintenance

Pre – installation preparation: Before installing the GE DS215TCQAG1BZZ01A, carefully check the installation environment. Ensure that the ambient temperature is within the specified range, and the area is free from excessive dust, moisture, and electromagnetic interference. Verify that the mounting rack or cabinet is properly grounded. Check the connection ports of the board and ensure that the mating connectors on other components are clean and in good condition. Follow the wiring diagrams provided in the official documentation to correctly connect all the input and output cables.

Maintenance recommendations: Regularly inspect the GE DS215TCQAG1BZZ01A for any signs of physical damage, such as cracks on the PCB or loose connections. Clean the board gently to remove any accumulated dust, which can affect its performance. Monitor the data it receives and transmits to ensure that it is functioning correctly. If there are any abnormal readings or control malfunctions, refer to the troubleshooting guide in the product manual. In case of complex issues, contact GE’s technical support team for assistance. Periodically update the board’s firmware if new versions are available to ensure optimal performance and compatibility with other components in the Mark V system.

Product Guarantee

GE stands firmly behind the quality of the GE DS215TCQAG1BZZ01A. The board undergoes rigorous testing during the manufacturing process to meet high – quality standards. GE offers a standard warranty period, during which any defects in materials or workmanship will be rectified free of charge. Their experienced technical support team is available to assist customers with installation, configuration, and any technical issues that may arise during the product’s lifespan. Whether it’s a problem with the board’s input/output functionality, communication with other components, or any other aspect, GE is committed to providing timely and effective solutions. This gives customers confidence in their investment and ensures the long – term, reliable operation of the DS215TCQAG1BZZ01A in various industrial applications.

We've got you covered

We give you access to a global supply of automation parts at your fingertips, ensuring that manufacturers around the world can avoid unnecessary downtime and continue to do what they do best – making our world possible.

Full 12-month warranty on all components

Dedicated after-sales support

Same-day dispatch on 1000s of parts

All units are fully tested

Continue Searching

We're here when you need us

What happens next?

- 1. Email confirmation

You will get an email confirming that we have received your enquiry. - 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition. - 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide Full 12-month warranty on all components

Full 12-month warranty on all components