Description

Product Overview

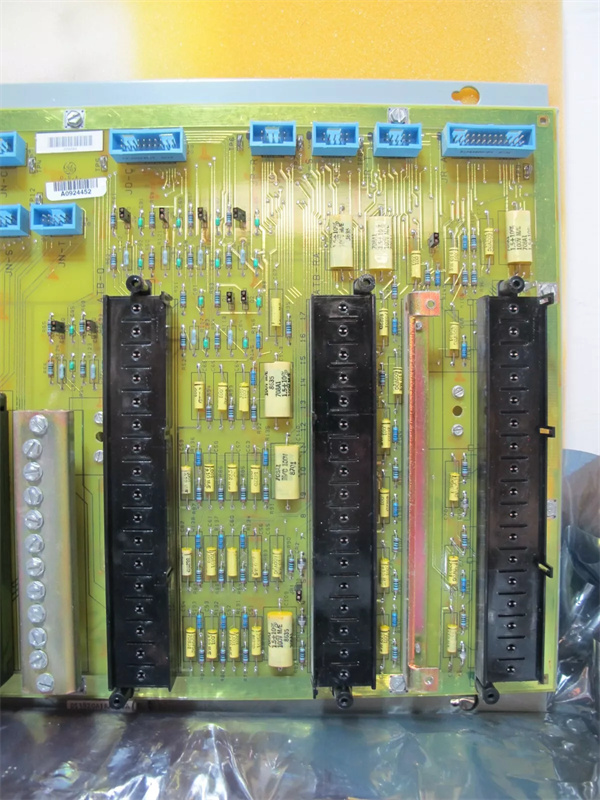

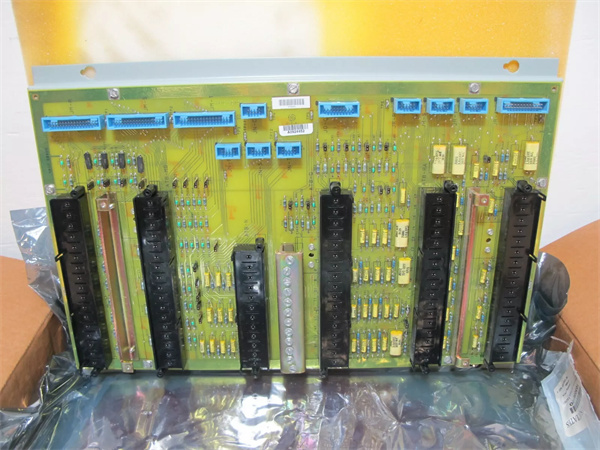

The GE DS3800XTFP1E1C is a highly specialized thyristor fan – out board, an integral part of GE’s renowned Speedtronic Mark IV series. This series is widely used in controlling and operating gas and steam turbines, playing a crucial role in energy – generation and industrial – process – related applications.

The DS3800XTFP1E1C board is designed to distribute and manage signals related to thyristor control within the turbine control system. It features eight red – colored plastic rectangles, each equipped with twelve circular ports, known as logic gates. These logic gates are labeled as js, jt, jy, jx (sense), jr, jq, jp, jn (sense), allowing for direct connection of a specific number of gate inputs without the need for additional wiring or interfacing circuitry. This design simplifies the signal – handling process and enhances the overall efficiency of the turbine control system. By ensuring accurate signal distribution, the DS3800XTFP1E1C contributes to the stable and reliable operation of gas and steam turbines, making it a vital component in industrial automation setups.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | DS3800XTFP1E1C |

| Manufacturer | GE |

| Product Type | Thyristor Fan – Out Board |

| Logic Gates | 8, each with 12 circular ports |

| Logic Gate Labels | js, jt, jy, jx (sense), jr, jq, jp, jn (sense) |

| Terminal Port | Small white plastic male with 6 metal prongs |

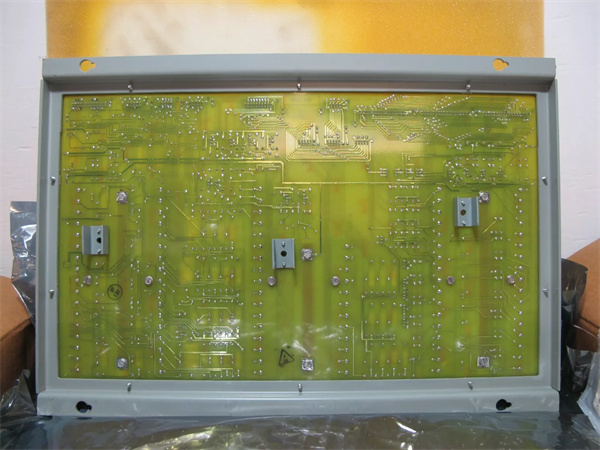

| Mounting Holes | 4 large pre – drilled holes in each corner, 2 small pre – drilled holes along bottom edge |

| Application | GE Speedtronic Mark IV gas and steam turbine control systems |

| Power Requirements | Dependent on the overall Mark IV system setup |

| Communication Interface | Integral to the Mark IV system’s internal communication network |

| Operating Temperature Range | Not specified in available data (assumed to be suitable for typical industrial environments, around 0 – 50°C) |

DS3800XAIC1C1C03

Main Features and Advantages

Simplified Signal Distribution

The DS3800XTFP1E1C‘s logic – gate – based design simplifies signal distribution. With its clearly labeled logic gates, it enables easy connection of gate inputs, reducing the complexity of wiring and minimizing the chances of connection errors. In a large – scale power – generation plant with numerous components in the turbine control system, this straightforward signal – distribution mechanism ensures that thyristor – related signals are accurately routed, enhancing the system’s reliability.

Robust Construction

Featuring pre – drilled holes in its corners and along the bottom edge, the board can be securely mounted within the control system. This robust construction not only ensures stable installation but also protects the internal components from vibrations and mechanical stress. In industrial settings where turbines operate under harsh conditions, the DS3800XTFP1E1C‘s durable build can withstand the environment, contributing to its long – term performance.

Integration with Mark IV System

As part of the Mark IV series, the DS3800XTFP1E1C is seamlessly integrated with other components in the system. It works in harmony with the overall control architecture, allowing for efficient communication and coordination. This integration means that it can be easily incorporated into existing Mark IV setups during upgrades or maintenance, providing flexibility for plant operators to enhance their turbine control capabilities without major system overhauls.

Application Field

The GE DS3800XTFP1E1C finds its primary application in power – generation plants that utilize gas and steam turbines. In gas – fired power plants, it plays a crucial role in controlling the thyristors that manage the electrical output of the turbines. By accurately distributing signals, it helps optimize the combustion process, ensuring efficient power generation.

In steam – turbine – based power plants, the DS3800XTFP1E1C is involved in regulating the speed and power output of the turbines. It receives and distributes signals related to steam flow, pressure, and temperature, which are then used to control the thyristors for precise turbine operation. This is essential for maintaining grid stability and ensuring a consistent power supply.

Industrial facilities that use turbines for mechanical drives, such as in the oil and gas industry for pumping and compression applications, also benefit from the DS3800XTFP1E1C. It enables reliable control of the turbines, which in turn ensures the smooth operation of critical industrial processes.

DS3800XAIC1C1C03

Related Products

- DS3800NAS1B1C: Another PCB in the GE lineup, part of the high – speed electronics in the Mark IV system. While the DS3800XTFP1E1C focuses on thyristor fan – out functions, the DS3800NAS1B1C may have different functions related to overall system performance optimization, like minimizing downtime in the Mark IV system.

- GE Mark IV Speedtronic Controllers: These controllers are the central units of the Mark IV system. The DS3800XTFP1E1C interfaces with them, receiving control commands and distributing relevant signals to the thyristors, working in tandem to control the gas and steam turbines.

- DS3800NFCF1E: A GE controller that might operate in a different aspect of the Mark IV system. It could be involved in overall system management, while the DS3800XTFP1E1C is more specialized in thyristor – related signal distribution.

- 173C8427CAG05: This product, when used with the DS3800XTFP1E1C, is part of a load – commutated inverter setup in the Mark IV system. It likely works together with the DS3800XTFP1E1C to control the electrical characteristics of the turbine – related power systems.

- GE Turbine – related Sensors: These sensors provide input data such as temperature, pressure, and speed to the Mark IV system. The DS3800XTFP1E1C uses this sensor data, processed by the system, to accurately distribute signals for thyristor control in gas and steam turbines.

Installation and Maintenance

Pre – installation preparation: Before installing the GE DS3800XTFP1E1C, ensure that the entire Mark IV turbine control system is powered off to prevent any electrical accidents. Check the board for any visible signs of damage during transit, such as bent pins or cracked components. Verify that the mounting location within the control cabinet has the appropriate space and is free from dust and debris. When installing, carefully align the board with the mounting holes and use the appropriate screws to secure it firmly. Connect the terminal ports according to the wiring diagram provided in the product manual, making sure all connections are tight.

Maintenance recommendations: Regularly inspect the DS3800XTFP1E1C for any signs of wear or loose connections. Check the logic gates and terminal ports for any corrosion or physical damage. Clean the board gently using a soft, dry brush to remove dust that could potentially affect its performance. In case of any abnormal behavior in the turbine control system related to thyristor control, start by checking the DS3800XTFP1E1C for possible faults. If a problem is detected, refer to the GE – provided troubleshooting guide or contact their technical support for further assistance.

Product Guarantee

GE stands behind the quality of the DS3800XTFP1E1C with a comprehensive product guarantee. The board is manufactured under strict quality – control measures to meet high – standard industrial requirements. In case of any defects in materials or workmanship, GE offers a reliable after – sales service. Their technical support team is available to provide remote diagnostic services and, if necessary, on – site assistance. GE typically provides a warranty period during which, if the DS3800XTFP1E1C fails due to quality – related issues, they will repair or replace the board free of charge. This reflects GE’s confidence in the product’s reliability and their commitment to customer satisfaction in industrial automation applications.