Description

Product Overview

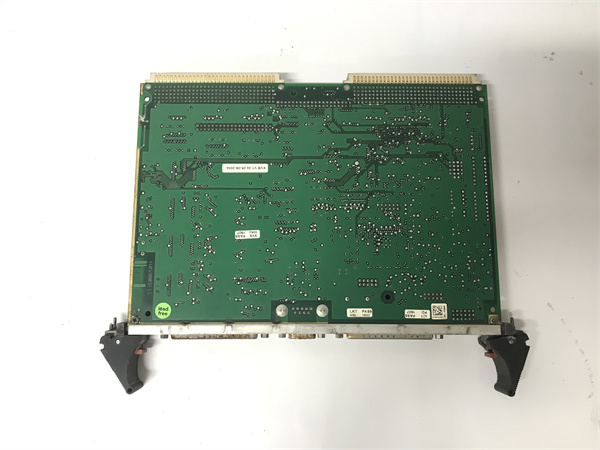

The GE EVMECNTM13 is a high – performance control module tailored for advanced industrial automation systems. As a key component within GE’s comprehensive suite of industrial control products, it stands out for its ability to offer reliable and precise control in diverse industrial settings. This module is designed to seamlessly integrate with existing systems, providing users with enhanced monitoring and control capabilities.

In the realm of industrial automation, the GE EVMECNTM13 plays a pivotal role. It can interface with various sensors and actuators, collecting real – time data and making informed control decisions. Its advanced design enables it to handle complex control algorithms, ensuring smooth operation of industrial processes. Whether in a manufacturing plant, a power generation facility, or an oil and gas refinery, the EVMECNTM13 serves as a crucial link in maintaining the efficiency and integrity of the automation system.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | EVMECNTM13 |

| Manufacturer | GE |

| Product Type | Control Module |

| Operating Voltage | 220 V |

| Input Frequency Range | 47 – 63 Hz |

| Output Frequency Range | 0 – 50 kHz |

| Communication Protocol | Ethernet/IP, Modbus TCP/IP |

| Environmental Rating | IP65 |

| Operating Temperature Range | – 40 °C to + 70 °C |

| Humidity Range | 0 % to 95 %, non – condensing |

| Weight | 1.5 kg |

| Dimensions | 200 mm x 150 mm x 100 mm |

EVMECNTM13

Main Features and Advantages

Robust Build and Environmental Resistance: The GE EVMECNTM13 has an IP65 rating, which means it is highly resistant to dust and water ingress. This makes it suitable for use in harsh industrial environments where exposure to such elements is common. With an operating temperature range from – 40 °C to + 70 °C, it can endure extreme conditions without a drop in performance, ensuring long – term reliability.

Versatile Communication Protocols: It supports multiple communication protocols, including Ethernet/IP and Modbus TCP/IP. This versatility allows the module to communicate effectively with a wide range of devices and systems, enhancing its integration capabilities across different industries. Whether it needs to connect with other control modules, sensors, or 上位机,the EVMECNTM13 can establish seamless data transfer.

Compact and Lightweight Design: Measuring 200 mm x 150 mm x 100 mm and weighing only 1.5 kg, the module is compact and lightweight. This not only makes installation straightforward but also saves valuable space in control cabinets. Its design also contributes to easier handling during maintenance and upgrades.

Precise Control and Monitoring: Engineered for high – precision operation, the EVMECNTM13 can accurately process input data from sensors and execute control commands. It provides real – time monitoring of industrial processes, allowing for quick detection of any anomalies and prompt corrective actions. This level of precision is essential for maintaining product quality and ensuring the efficient operation of industrial systems.

Versatile Communication Protocols: It supports multiple communication protocols, including Ethernet/IP and Modbus TCP/IP. This versatility allows the module to communicate effectively with a wide range of devices and systems, enhancing its integration capabilities across different industries. Whether it needs to connect with other control modules, sensors, or 上位机,the EVMECNTM13 can establish seamless data transfer.

Compact and Lightweight Design: Measuring 200 mm x 150 mm x 100 mm and weighing only 1.5 kg, the module is compact and lightweight. This not only makes installation straightforward but also saves valuable space in control cabinets. Its design also contributes to easier handling during maintenance and upgrades.

Precise Control and Monitoring: Engineered for high – precision operation, the EVMECNTM13 can accurately process input data from sensors and execute control commands. It provides real – time monitoring of industrial processes, allowing for quick detection of any anomalies and prompt corrective actions. This level of precision is essential for maintaining product quality and ensuring the efficient operation of industrial systems.

Application Field

Manufacturing Industry: In manufacturing plants, the GE EVMECNTM13 is used to control production lines. It can interface with sensors that detect the position of parts, the status of machinery, and the flow of materials. By precisely controlling actuators, it ensures smooth operation of conveyor belts, robotic arms, and other manufacturing equipment. For example, it can adjust the speed of a conveyor belt based on the detection of product jams, optimizing production efficiency.

Power Generation: Power plants rely on the EVMECNTM13 to monitor and control various aspects of power generation. It can receive data from sensors that measure parameters such as temperature, pressure, and voltage in generators, turbines, and transformers. Based on this data, it can make control decisions to maintain stable power output, protect equipment from overloading, and ensure the safe operation of the power generation process.

Oil and Gas Sector: In oil refineries and gas processing plants, the module plays a crucial role. It can connect to sensors that monitor the flow rate, pressure, and composition of oil and gas. By controlling valves and pumps, it helps in regulating the flow of these resources, ensuring efficient processing and preventing leaks or other safety hazards. For instance, it can adjust the opening of a pressure – relief valve in response to changing pressure levels in a pipeline.

Power Generation: Power plants rely on the EVMECNTM13 to monitor and control various aspects of power generation. It can receive data from sensors that measure parameters such as temperature, pressure, and voltage in generators, turbines, and transformers. Based on this data, it can make control decisions to maintain stable power output, protect equipment from overloading, and ensure the safe operation of the power generation process.

Oil and Gas Sector: In oil refineries and gas processing plants, the module plays a crucial role. It can connect to sensors that monitor the flow rate, pressure, and composition of oil and gas. By controlling valves and pumps, it helps in regulating the flow of these resources, ensuring efficient processing and preventing leaks or other safety hazards. For instance, it can adjust the opening of a pressure – relief valve in response to changing pressure levels in a pipeline.

EVMECNTM13

Related Products

EVMECNTM12: Likely a previous – generation or related – series product. It may have similar functions but could differ in terms of performance, such as having a lower processing speed or fewer supported communication protocols compared to the EVMECNTM13.

GE IC670MDL240J: A digital input module. While the EVMECNTM13 is a control module, the IC670MDL240J can work in tandem with it. The input module can feed digital signals to the EVMECNTM13, which then processes and uses this data for control operations.

VMIPMC – 5565: An optic reflective memory card. In a complex industrial control system, the EVMECNTM13 may communicate with the VMIPMC – 5565 to share data. The memory card can store and transfer data that the EVMECNTM13 needs for its control algorithms or for long – term data logging.

DS200DPCBG1AAA: A contact input group isolation terminal board. It can be used to interface with sensors and isolate input signals before they reach the EVMECNTM13. This helps in protecting the control module from electrical interference and ensuring the accuracy of input data.

GE IS200WREAS1ADB: A turbine – related control board. In power generation applications involving turbines, the EVMECNTM13 may collaborate with the IS200WREAS1ADB. The latter focuses more on turbine – specific control functions, while the EVMECNTM13 may handle overall system integration and additional control tasks related to other components in the power plant.

GE IC670MDL240J: A digital input module. While the EVMECNTM13 is a control module, the IC670MDL240J can work in tandem with it. The input module can feed digital signals to the EVMECNTM13, which then processes and uses this data for control operations.

VMIPMC – 5565: An optic reflective memory card. In a complex industrial control system, the EVMECNTM13 may communicate with the VMIPMC – 5565 to share data. The memory card can store and transfer data that the EVMECNTM13 needs for its control algorithms or for long – term data logging.

DS200DPCBG1AAA: A contact input group isolation terminal board. It can be used to interface with sensors and isolate input signals before they reach the EVMECNTM13. This helps in protecting the control module from electrical interference and ensuring the accuracy of input data.

GE IS200WREAS1ADB: A turbine – related control board. In power generation applications involving turbines, the EVMECNTM13 may collaborate with the IS200WREAS1ADB. The latter focuses more on turbine – specific control functions, while the EVMECNTM13 may handle overall system integration and additional control tasks related to other components in the power plant.

Installation and Maintenance

Pre – installation preparation: Before installing the GE EVMECNTM13, ensure that the power to the target system is turned off to avoid electrical accidents. Check the module for any visible signs of damage during transit. Verify that the installation location meets the environmental requirements, such as temperature and humidity conditions specified in the technical specifications. Make sure the mounting surface is clean and flat. Also, confirm that the wiring connections are properly planned, and the wires used are of appropriate gauge to handle the electrical load.

Maintenance recommendations: Regularly monitor the performance of the EVMECNTM13 by checking for any abnormal behavior in the control system. Look for signs of overheating, such as unusual warmth or discoloration of the module. Periodically clean the module to remove dust and debris, as these can affect its electrical performance. If any communication issues occur, check the integrity of the communication cables and the configured communication protocols. Keep spare parts on hand, such as replacement modules, to minimize downtime in case of a component failure.

Maintenance recommendations: Regularly monitor the performance of the EVMECNTM13 by checking for any abnormal behavior in the control system. Look for signs of overheating, such as unusual warmth or discoloration of the module. Periodically clean the module to remove dust and debris, as these can affect its electrical performance. If any communication issues occur, check the integrity of the communication cables and the configured communication protocols. Keep spare parts on hand, such as replacement modules, to minimize downtime in case of a component failure.

Product Guarantee

GE offers a comprehensive product guarantee for the EVMECNTM13. The module undergoes strict quality control procedures during manufacturing to meet high – industry standards. In case of any manufacturing defects, GE provides a warranty to cover repairs or replacements. Their global network of technical support teams is available to assist customers. Whether it’s providing guidance on installation, helping with troubleshooting complex issues, or offering advice on maintenance, GE’s experts are committed to ensuring the long – term, reliable operation of the EVMECNTM13. This reflects GE’s confidence in the product’s quality and their dedication to customer satisfaction.