Description

Product Overview

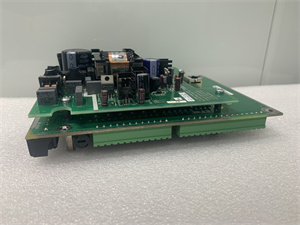

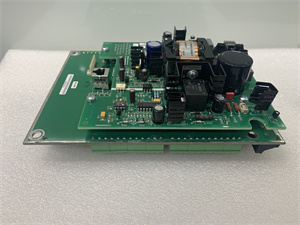

The GE 369 – A200 is a highly specialized communication module within GE’s extensive portfolio of industrial automation products. Designed to play a pivotal role in DCS (Distributed Control Systems) and other industrial setups, it enables seamless data transfer and interaction between different components. This module is engineered to support a wide range of communication protocols, making it adaptable to diverse industrial environments. Its core function is to act as a reliable bridge for sending and receiving data, ensuring that control systems can efficiently manage and monitor various processes. As part of GE’s industrial automation series, the 369 – A200 is positioned as a high – performance solution for industries that demand stable and fast communication capabilities. It significantly enhances the overall functionality of an automation system by enabling better integration of devices, leading to improved productivity and more precise control.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | 369 – A200 |

| Manufacturer | GE |

| Product Type | Communication Module |

| Communication Protocols | Supports common industrial protocols (e.g., Modbus RTU as a standard option in related 369 series, details may vary for this model) |

| Input Voltage | [Specify typical industrial input voltage if available, e.g., 24 VDC] |

| Connector Types | Equipped with front and rear signal connectors for easy connection; may have SCXIbus connector as seen in related products |

| Hold Trigger Signal Source | Software – selectable; can be from front or rear signal connector’s HOLDTRIG signal or inverse of TRIG1 from SCXIbus connector (similar to related 369 series features) |

| Hold Trigger Signal Output | Can be sent out via HOLDTRIG pins of signal connectors or onto TRIG1 in inverted form |

| Dimensions | [If available, provide length x width x height in mm] |

| Weight | [If available, provide weight in kg] |

| Operating Temperature | [Specify suitable temperature range for industrial use] |

| Humidity Range | [State acceptable humidity levels for operation] |

GE 369-A200

Main Features and Advantages

Flexible Communication Configuration: The GE 369 – A200 offers software – selectable options for its hold trigger signal source. This flexibility allows it to be easily integrated into different industrial setups, adapting to the specific requirements of the control system. For example, it can choose between the HOLDTRIG signal from the front or rear signal connectors or the inverse of TRIG1 from the SCXIbus connector, providing multiple choices for seamless communication connection.

Reliable Signal Transmission: It ensures stable data transfer with its well – designed signal output capabilities. The hold trigger signal can be sent out through the HOLDTRIG pins of the signal connectors or onto TRIG1 in an inverted form. Hardware safeguards prevent incorrect signal selections, guaranteeing that the module functions accurately and consistently, minimizing the risk of communication errors in critical industrial processes.

Compatibility with Industrial Standards: As part of GE’s industrial product line, the 369 – A200 is likely to be compatible with common industrial communication standards. This compatibility enables it to work harmoniously with a wide array of devices from different manufacturers, promoting interoperability within industrial automation systems. It can be easily incorporated into existing infrastructure, reducing the need for major system overhauls when upgrading or adding new communication capabilities.

Reliable Signal Transmission: It ensures stable data transfer with its well – designed signal output capabilities. The hold trigger signal can be sent out through the HOLDTRIG pins of the signal connectors or onto TRIG1 in an inverted form. Hardware safeguards prevent incorrect signal selections, guaranteeing that the module functions accurately and consistently, minimizing the risk of communication errors in critical industrial processes.

Compatibility with Industrial Standards: As part of GE’s industrial product line, the 369 – A200 is likely to be compatible with common industrial communication standards. This compatibility enables it to work harmoniously with a wide array of devices from different manufacturers, promoting interoperability within industrial automation systems. It can be easily incorporated into existing infrastructure, reducing the need for major system overhauls when upgrading or adding new communication capabilities.

GE 369-A200

Application Field

In industrial automation, the GE 369 – A200 is widely used in manufacturing plants. For instance, in an automotive manufacturing assembly line, it can communicate with sensors, actuators, and programmable logic controllers (PLCs). It helps in relaying real – time data about the position of robotic arms, the status of conveyor belts, and the quality of parts being assembled. In the energy sector, such as in power generation plants, the module plays a crucial role. It can transmit data between different control systems, like the turbine control system and the overall plant management system. This allows for better monitoring and control of power generation processes, ensuring optimal efficiency and safe operation. Additionally, in chemical processing plants, the 369 – A200 enables communication between process control devices. It can send and receive data related to temperature, pressure, and flow rate sensors, and then transfer this information to the central control room for analysis and decision – making, ensuring smooth and safe chemical production processes.

Related Products

- GE 369 – C100: Likely part of the same product family. It may have different communication capabilities or be designed for specific applications within the industrial control space, perhaps with a different focus on protocol support or interface configuration compared to the 369 – A200.

- GE IC697ACC722B: A different type of module, perhaps a power – related or accessory module. It could be used in conjunction with the 369 – A200 in a larger industrial control system, providing power support or additional functionality to ensure the stable operation of the communication module.

- GE DS200TCPDG1BEC: This might be a control or data – handling module. It may interact with the 369 – A200 in an industrial setup, with the 369 – A200 handling communication while the DS200TCPDG1BEC manages specific data processing or control tasks related to the overall system operation.

- GE VMIVME – 7750: A high – performance embedded communication module. While the 369 – A200 is focused on general industrial communication within DCS and related systems, the VMIVME – 7750 may target more specialized or high – end applications, but they could both be used in complex industrial automation networks at different levels or for different functions.

- GE IC693CPU372 – AE: A CPU module. In an industrial control system, the 369 – A200 can communicate with the IC693CPU372 – AE, providing it with data received from various sensors or devices, and in turn, receiving control commands from the CPU to regulate communication operations.

Installation and Maintenance

Pre – installation preparation: Before installing the GE 369 – A200, ensure that the power supply to the target industrial system is turned off. Thoroughly check the installation environment to confirm it meets the specified temperature, humidity, and electromagnetic interference requirements. Inspect all the connectors on the module and the system where it will be installed to make sure they are clean and free from damage. Familiarize yourself with the module’s user manual to understand the correct connection procedures for different types of signal and power connectors.

Maintenance recommendations: Regularly monitor the communication status of the 369 – A200 by checking for any error messages or inconsistent data transfer. Clean the module periodically to remove dust and debris that could potentially affect its performance. Periodically update the module’s firmware if available, as this can enhance its functionality and compatibility. In case of any communication failures, carefully review the connection settings and check for any loose connectors. If the problem persists, refer to the detailed troubleshooting section in the product manual or contact GE’s technical support for further assistance.

Maintenance recommendations: Regularly monitor the communication status of the 369 – A200 by checking for any error messages or inconsistent data transfer. Clean the module periodically to remove dust and debris that could potentially affect its performance. Periodically update the module’s firmware if available, as this can enhance its functionality and compatibility. In case of any communication failures, carefully review the connection settings and check for any loose connectors. If the problem persists, refer to the detailed troubleshooting section in the product manual or contact GE’s technical support for further assistance.

Product Guarantee

GE stands firmly behind the quality of the GE 369 – A200. The module undergoes strict quality control during the manufacturing process to ensure its reliability and high – performance operation. GE offers a standard warranty period, during which any defects in materials or workmanship will be addressed free of charge. Their team of highly skilled technical experts is available to provide support for installation, configuration, and troubleshooting. Whether it’s a query about the module’s functionality or assistance in resolving a complex technical issue, customers can rely on GE’s prompt and efficient customer service. This commitment not only reflects GE’s confidence in the product but also their dedication to ensuring customers have a seamless experience when using the 369 – A200 in their industrial applications.