Description

Product Overview

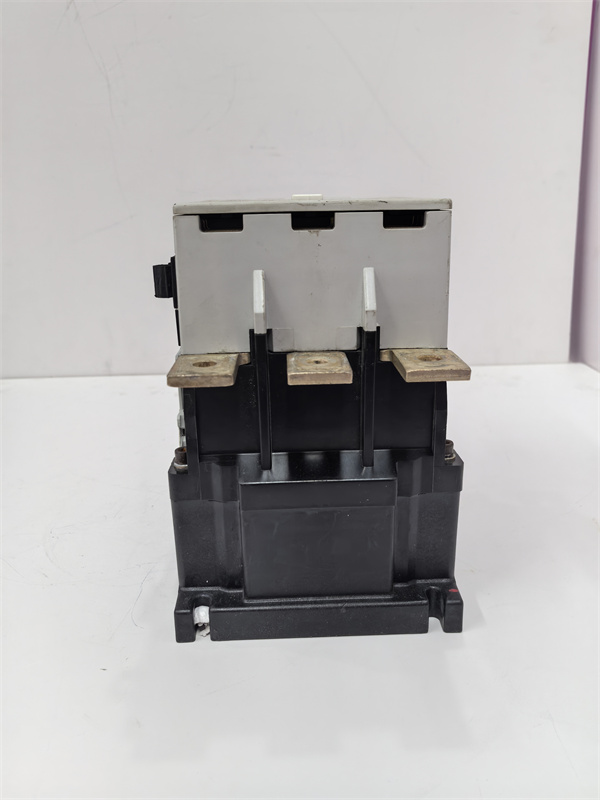

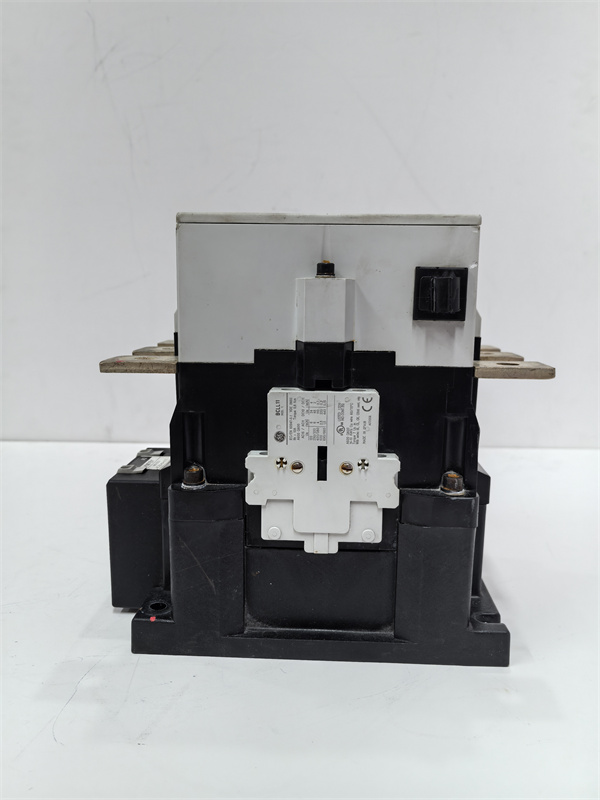

The GE CK11CE300 is a high – performance 3 – pole contactor by General Electric, designed for critical industrial power – control applications. As part of GE’s extensive CK series, it is engineered to meet the demanding requirements of industrial automation systems. This contactor is a crucial component in power distribution setups, enabling the efficient connection and disconnection of high – power electrical circuits.

With a maximum current rating of 600A and the ability to handle voltages up to 600V, the GE CK11CE300 can manage large – scale electrical loads. Its coil voltage range of 440 – 500V at a frequency of 50 – 60Hz offers flexibility in different power supply environments. In industrial settings, it plays a key role in controlling motors, pumps, and other heavy – duty equipment, ensuring stable operation and contributing to overall system reliability. Its robust design allows it to withstand harsh industrial conditions, making it a reliable choice for long – term use in various industrial applications.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | CK11CE300 |

| Manufacturer | General Electric |

| Product Type | Contactor |

| Number of Poles | 3 |

| Rated Current | 600A |

| Rated Voltage | 600V |

| Coil Voltage | 440 – 500V |

| Frequency | 50 – 60Hz |

| Max HP Rating | 500HP |

| Contact Material | High – quality alloy |

| Enclosure Type | Standard industrial |

| Mounting Style | Panel – mountable |

| Weight | Not specified |

GE CK11CE300

Main Features and Advantages

High – Current Handling Capacity: The GE CK11CE300 is designed to handle large currents, with a 600A rating. This makes it suitable for controlling high – power equipment such as large – scale motors in manufacturing plants or powerful pumps in industrial processes. It can ensure stable power supply to these high – load devices, preventing issues like voltage drops and electrical malfunctions.

3 – Pole Design for Three – Phase Applications: Its 3 – pole configuration is ideal for three – phase power systems, which are widely used in industrial applications. This design enables efficient power distribution and control in three – phase equipment, ensuring balanced operation and reducing the risk of phase – related problems.

Wide Coil Voltage Range: With a coil voltage range of 440 – 500V, the contactor can adapt to different power supply conditions. This flexibility is beneficial in industrial facilities where power supply voltages may vary slightly. It eliminates the need for additional voltage – conversion equipment in many cases, simplifying the electrical setup and reducing costs.

Durable Construction: Built with high – quality materials, the GE CK11CE300 is designed to withstand harsh industrial environments. It can endure factors like dust, vibration, and temperature fluctuations. The contactor’s high – quality alloy contact material ensures excellent electrical conductivity and long – term durability, reducing the need for frequent replacements and minimizing maintenance requirements.

Application Field

Manufacturing Industry: In manufacturing plants, the GE CK11CE300 is used to control the power supply of large – scale motors. For example, in a car manufacturing factory, it can control the motors of conveyor belts that transport car parts along the assembly line. It also manages the power for industrial pumps that are used in coolant circulation systems or for moving various fluids within the manufacturing process.

Power Generation Sector: In power plants, the GE CK11CE300 plays a role in controlling auxiliary equipment. It can switch on and off the power – consuming devices in the power generation process, such as the motors that operate the fans for cooling the generators or the pumps that supply water for steam production.

Mining Industry: Mines rely on heavy – duty machinery for extraction and transportation. The GE CK11CE300 is used to control crushers that break large rocks into smaller pieces and conveyor belts that transport the mined materials. Its high – current – handling capacity is crucial for powering these large – scale mining machines.

Oil and Gas Industry: In the oil and gas sector, the GE CK11CE300 is used to manage the power of pumps and compressors. Pumps are used for extracting oil and gas from wells and for transporting them through pipelines. Compressors are used to increase the pressure of the gas for efficient transportation. The contactor ensures reliable power control for these critical operations.

GE CK11CE300

Related Products

CK08CE311J: A smaller – capacity contactor in the same series. It is suitable for applications with lower power requirements compared to the GE CK11CE300. For example, it may be used to control smaller motors or less power – intensive equipment in industrial settings.

CK09BE311D: Another contactor with different coil voltage options and horsepower ratings. It can be used in applications where the power supply characteristics or the load requirements are different from those suitable for the GE CK11CE300.

CK11CE311J: Shares similarities with the GE CK11CE300 but has a different coil voltage specification. This provides an alternative for scenarios where a different coil voltage is more appropriate for the electrical system.

CK12BE311J: A contactor with a higher horsepower rating. It can be used in applications that require even more power – handling capacity than the GE CK11CE300, such as controlling extremely large motors or high – power industrial equipment.

CK75CE311W24 – 60: This contactor has specific voltage and current ratings that differ from the GE CK11CE300. It may be used in applications where the electrical parameters need to be more precisely matched to the equipment’s power requirements.

CK09BE311D: Another contactor with different coil voltage options and horsepower ratings. It can be used in applications where the power supply characteristics or the load requirements are different from those suitable for the GE CK11CE300.

CK11CE311J: Shares similarities with the GE CK11CE300 but has a different coil voltage specification. This provides an alternative for scenarios where a different coil voltage is more appropriate for the electrical system.

CK12BE311J: A contactor with a higher horsepower rating. It can be used in applications that require even more power – handling capacity than the GE CK11CE300, such as controlling extremely large motors or high – power industrial equipment.

CK75CE311W24 – 60: This contactor has specific voltage and current ratings that differ from the GE CK11CE300. It may be used in applications where the electrical parameters need to be more precisely matched to the equipment’s power requirements.

Installation and Maintenance

Pre – installation preparation: Before installing the GE CK11CE300 contactor, ensure that the power supply is completely turned off. Check the physical dimensions of the contactor to ensure it can be properly mounted on the designated panel. Verify that the power supply voltage and frequency match the specified range of the GE CK11CE300. Inspect the mounting area for any signs of damage or instability. Make sure all the necessary tools and hardware for installation are at hand.

Maintenance recommendations: Regularly inspect the GE CK11CE300 for any signs of wear, such as burned contacts or loose connections. Clean the contactor periodically to remove dust and debris, as these can affect its performance over time. Monitor the coil voltage regularly to ensure it remains within the specified range. If any abnormal noises or overheating is detected, immediately stop the operation and investigate the cause. Replace any damaged components promptly to maintain the normal operation of the GE CK11CE300.

Product Guarantee

GE stands firmly behind the quality of the GE CK11CE300 contactor. The product undergoes strict quality control during manufacturing to ensure it meets high – industry standards. GE offers a standard warranty period, during which any manufacturing defects will be rectified free of charge. Their global network of technical support teams is available to assist customers with installation, configuration, and troubleshooting. Whether it’s answering questions about the contactor’s operation or providing guidance on maintenance, customers can rely on GE’s expertise. This guarantee reflects GE’s confidence in the product and its commitment to providing reliable industrial power – control solutions, giving customers peace of mind when using the GE CK11CE300 in their critical applications.