Description

Product Overview

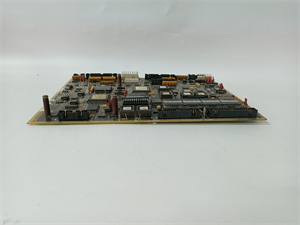

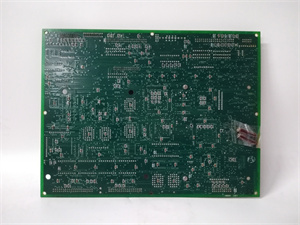

The GE DS200LDCCH1AGA is a discrete input module designed to play a critical role in industrial control systems. As part of GE’s comprehensive suite of industrial automation products, the DS200LDCCH1AGA is engineered to provide reliable and accurate input signal handling. It is widely utilized in various industrial applications where precise monitoring and control of discrete signals are essential.

This module is specifically designed for applications within GE’s Mark VI and Mark VIe distributed control systems (DCS), which are commonly used in industrial settings, especially in power generation and other large – scale automated processes. The DS200LDCCH1AGA interfaces with field devices, collecting and processing discrete input signals for the control system. With 24 dry – contact inputs, it can handle a significant number of input sources, making it suitable for complex industrial setups. It is built to work in harmony with other components in the DCS, ensuring seamless data flow and overall system efficiency.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | DS200LDCCH1AGA |

| Manufacturer | GE |

| Product Type | Discrete Input Module |

| Number of Inputs | 24 dry – contact inputs |

| Input Voltage | Nominal 24 VDC |

| Connection Type | Connected to two barrier – style terminal blocks on the board |

| Isolation | Group isolation for enhanced safety and noise reduction |

| Noise Reduction | Built – in circuits to protect against surges and high – frequency noise |

| Operating Temperature Range | 0°C – 55°C |

| Storage Temperature Range | – 40°C – 85°C |

| Relative Humidity | 5% – 95%, non – condensing |

| Mounting | Suitable for mounting within a VME rack as part of a larger control system |

| Weight | Approximately [specify if available] |

DS200LDCCH1AGA

Main Features and Advantages

High – Density Inputs

The DS200LDCCH1AGA offers 24 dry – contact inputs, providing a high – density solution for industrial control applications. This allows for the connection of numerous field devices, such as sensors and switches, in a single module, reducing the need for multiple modules and simplifying the overall system design.

Group Isolation

With group isolation, the module enhances safety and reduces electrical interference. This isolation feature protects the control system from potential electrical faults in the field devices and helps in maintaining the integrity of the input signals, especially in electrically noisy industrial environments.

Noise – Resistant Design

The built – in noise reduction circuits in the DS200LDCCH1AGA safeguard against surges and high – frequency noise. This ensures that the input signals received by the module are clean and accurate, preventing false readings and incorrect control actions. As a result, the overall reliability of the industrial control system is significantly improved.

Compatibility with DCS

Designed to be an integral part of GE’s Mark VI and Mark VIe DCS, the DS200LDCCH1AGA seamlessly integrates with other components in the system. It can communicate effectively with the central control unit and other I/O modules, enabling smooth data transfer and coordinated control operations across the entire industrial process.

DS200LDCCH1AGA

Application Field

Power Generation

In power plants, the DS200LDCCH1AGA is used to monitor various discrete signals. For example, it can detect the status of switches in turbine control systems, such as the position of inlet valves or the state of emergency stop switches. By accurately relaying these signals to the control system, it helps in ensuring the safe and efficient operation of the turbines. In generator control, it can monitor the status of protective relays, providing real – time information to the operators and enabling quick response in case of any anomalies.

Manufacturing

In manufacturing facilities, the module plays a crucial role in production line control. It can monitor the status of sensors that detect the presence of products on conveyor belts, the open – close status of pneumatic valves in robotic arms, or the operation of limit switches on machinery. Based on these input signals, the control system can make decisions to regulate the speed of conveyors, initiate the next phase of robotic operations, or stop the machinery in case of any malfunctions, thus optimizing the production process and minimizing downtime.

Process Industries

In industries like chemical or petrochemical plants, the DS200LDCCH1AGA is used to monitor the status of various process – related equipment. It can detect the open – close status of isolation valves in chemical reactors, the operation of pumps in the fluid transfer systems, or the state of level sensors in storage tanks. This information is vital for maintaining the proper flow of chemicals, ensuring the safety of the process, and optimizing the overall production efficiency.

Related Products

- GE DS200LDCCH1AKA: Similar to the DS200LDCCH1AGA, it is also part of the same family of modules. It may have some differences in terms of specific features or compatibility, but generally serves a similar purpose of handling discrete inputs within GE’s control systems.

- GE DS200LDCCH1ANA: Another related module that likely shares some design and functionality aspects with the DS200LDCCH1AGA. However, it may have variations in input types, voltage ratings, or the number of channels, offering different options for specific industrial applications.

- GE Mark VI and Mark VIe DCS Processors: These processors work in tandem with the DS200LDCCH1AGA module. They receive the processed input signals from the module and execute control algorithms, making decisions to control the overall industrial process.

- GE I/O Terminal Blocks: Used to connect the field devices to the DS200LDCCH1AGA module. Different types of terminal blocks may be available, providing flexibility in wiring and connection methods.

- GE Power Supply Modules: Provide the necessary power for the DS200LDCCH1AGA to operate. They ensure a stable and reliable power source, which is crucial for the proper functioning of the module in industrial environments.

Installation and Maintenance

Pre – installation preparation: Before installing the DS200LDCCH1AGA, ensure that the power supply voltage is stable and matches the module’s requirement of 24 VDC. Check the VME rack where it will be mounted for any signs of damage or improper wiring. Read the installation manual carefully to understand the correct way to mount the module and connect the input wires. Prepare the necessary tools, such as screwdrivers and wire strippers. Disconnect the power from the entire control system to avoid any electrical hazards during installation.

Maintenance recommendations: Regularly inspect the DS200LDCCH1AGA for any signs of physical damage, like cracks in the casing or loose connections. Monitor the input signals to ensure they are within the expected range and that there are no false readings. Clean the module periodically to prevent dust and debris accumulation, which could affect its performance. If any issues are detected, refer to the troubleshooting guide in the user manual. In case of a malfunctioning input channel, first check the connected field device and wiring before considering replacing the module.

Product Guarantee

GE stands firmly behind the quality of the DS200LDCCH1AGA module. It undergoes rigorous testing during the manufacturing process to meet high – quality standards. GE offers a standard warranty period, during which any defects in materials or workmanship will be rectified free of charge. Their experienced technical support team is always available to assist customers with installation, configuration, and any technical issues that may arise during the product’s lifespan. Whether it’s a problem with input signal handling, noise interference, or general module functionality, GE is committed to providing timely and effective solutions, ensuring the DS200LDCCH1AGA operates smoothly and reliably, giving customers confidence in their investment.