Description

Product Overview

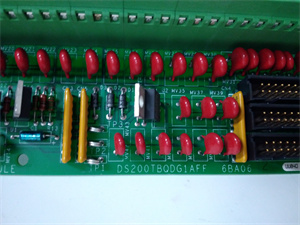

The General Electric DS200TBQDG1AFF is a high – performance RST extended analog terminal board that plays a pivotal role in industrial automation and control systems. As part of GE’s comprehensive lineup of industrial components, it is designed to meet the complex demands of modern industrial applications.

This terminal board is engineered to interface with GE RSTi EP and RSTi EPx modules, providing crucial additional analog input and output capabilities. It serves as a reliable link between different parts of the control system, allowing for seamless integration of analog – based devices. In industrial settings, accurate analog signal handling is essential for processes such as monitoring and controlling temperature, pressure, and flow rates. The DS200TBQDG1AFF enables precise management of these signals, enhancing the overall efficiency and accuracy of industrial operations. Whether in a large – scale manufacturing plant or a power generation facility, this board ensures stable and reliable control, contributing to optimized production processes.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | DS200TBQDG1AFF |

| Manufacturer | General Electric |

| Product Type | RST Extended Analog Terminal Board |

| Terminal Blocks | 2, each with 107 signal line terminals |

| Test Points | 3 (ID: TP1, TP2, TP3) |

| Jumpers | 2 |

| Connectors | 3 34 – pin connectors |

| Input Signals | LVDT input signals |

| Output Signals | Milliamp output |

| Operating Temperature Range | – 40 °C to 85 °C |

| Humidity Range | 5 – 95% non – condensing |

| Dimensions | [Please refer to the official manual for exact dimensions] |

| Weight | [Please refer to the official manual for exact weight] |

| Power Requirements | [Specify power requirements if available] |

DS200TBQDG1AFF

Main Features and Advantages

Reliable Signal Handling: The GE DS200TBQDG1AFF is built to handle analog signals with high precision. Its design ensures minimal signal interference and distortion, which is crucial for accurate control in industrial processes. For example, in a chemical plant where precise temperature and pressure control are essential for product quality, the board’s reliable signal handling capabilities guarantee that the control system receives and processes accurate data, leading to consistent production.

Flexible Configuration: With its two jumpers, the board allows for flexible configuration to meet the specific requirements of different industrial applications. Installers can use the jumpers to define the processing of the board according to the needs of the drive, as per the information provided in the accompanying documentation. This flexibility makes it adaptable to a wide range of industrial setups, from simple manufacturing lines to complex power generation systems.

Multiple I/O Options: Equipped with two terminal blocks containing 107 signal line terminals each, along with multiple test points and three 34 – pin connectors, the DS200TBQDG1AFF offers a rich set of input and output options. This enables it to interface with a large number of analog devices, expanding the functionality of the overall control system. It can be used to connect sensors, actuators, and other analog – based equipment, providing a comprehensive solution for industrial control.

Flexible Configuration: With its two jumpers, the board allows for flexible configuration to meet the specific requirements of different industrial applications. Installers can use the jumpers to define the processing of the board according to the needs of the drive, as per the information provided in the accompanying documentation. This flexibility makes it adaptable to a wide range of industrial setups, from simple manufacturing lines to complex power generation systems.

Multiple I/O Options: Equipped with two terminal blocks containing 107 signal line terminals each, along with multiple test points and three 34 – pin connectors, the DS200TBQDG1AFF offers a rich set of input and output options. This enables it to interface with a large number of analog devices, expanding the functionality of the overall control system. It can be used to connect sensors, actuators, and other analog – based equipment, providing a comprehensive solution for industrial control.

Application Field

Power Generation: In power plants, the GE DS200TBQDG1AFF is used to monitor and control various parameters related to power generation. It can interface with sensors that measure steam pressure, turbine speed, and generator voltage. By accurately handling these analog signals, the board helps in maintaining stable power output, optimizing the efficiency of the power generation process, and ensuring the safe operation of the plant.

Manufacturing Industry: In manufacturing plants, the board is employed in production line control systems. It can be used to manage analog signals from sensors that monitor factors such as product dimensions, machine vibrations, and material flow. For instance, in a precision – machining factory, the DS200TBQDG1AFF can connect to sensors on machine tools to ensure accurate cutting and shaping of parts, thereby improving product quality and production efficiency.

Process Industries: Industries such as chemical, food and beverage, and oil and gas rely on the DS200TBQDG1AFF for process control. It can handle analog signals related to temperature, pressure, and chemical composition in reactors, pipelines, and storage tanks. In a chemical plant, the board can be used to control the flow of reactants based on real – time sensor data, ensuring proper chemical reactions and product quality.

Manufacturing Industry: In manufacturing plants, the board is employed in production line control systems. It can be used to manage analog signals from sensors that monitor factors such as product dimensions, machine vibrations, and material flow. For instance, in a precision – machining factory, the DS200TBQDG1AFF can connect to sensors on machine tools to ensure accurate cutting and shaping of parts, thereby improving product quality and production efficiency.

Process Industries: Industries such as chemical, food and beverage, and oil and gas rely on the DS200TBQDG1AFF for process control. It can handle analog signals related to temperature, pressure, and chemical composition in reactors, pipelines, and storage tanks. In a chemical plant, the board can be used to control the flow of reactants based on real – time sensor data, ensuring proper chemical reactions and product quality.

DS200TBQDG1AFF

Related Products

- GE DS200TBQAG1ABB: It may be another terminal board in the same product family, perhaps with different input/output configurations or performance characteristics. It could be used as an alternative in applications where the specific features of the DS200TBQDG1AFF are not fully required.

- GE RSTi EP Module: The DS200TBQDG1AFF is designed to work in tandem with the GE RSTi EP module. The module provides the computational and control capabilities, while the DS200TBQDG1AFF extends its analog I/O functionality, together forming a more comprehensive control solution.

- GE RSTi EPx Module: Similar to the RSTi EP module, the RSTi EPx module can also be paired with the DS200TBQDG1AFF. The EPx version might offer enhanced features such as higher processing power or additional communication interfaces, allowing for more complex industrial control scenarios when combined with the terminal board.

- GE Other Analog Terminal Boards: There are other analog terminal boards in GE’s product range. They may have different numbers of terminals, different signal handling capabilities, or be designed for specific types of industrial applications. For example, some may be optimized for high – voltage analog signals, while the DS200TBQDG1AFF is more general – purpose for a wide range of analog signal handling in industrial automation.

- GE Control System Software: Software solutions from GE are used to program and manage the operation of the DS200TBQDG1AFF within the overall control system. These software packages provide the user interface, configuration tools, and control logic programming capabilities to fully utilize the board’s features in industrial applications.

Installation and Maintenance

Pre – installation preparation: Before installing the GE DS200TBQDG1AFF, carefully review the installation manual provided by GE. Ensure that the installation environment meets the specified temperature and humidity requirements. Check the integrity of the board and all its components, including the terminal blocks, jumpers, and connectors. Prepare the necessary tools for installation, such as screwdrivers and wire strippers. If replacing an existing board, note the jumper positions on the old board as they need to be replicated on the new DS200TBQDG1AFF for proper functionality.

Maintenance recommendations: Regularly inspect the DS200TBQDG1AFF for any signs of physical damage, such as cracks on the board or loose connections. Clean the board gently to remove dust and debris that could affect its performance. Use appropriate testing equipment to check the functionality of the test points and the integrity of the input/output signals. If any issues are detected, such as abnormal signal readings or communication problems, refer to the troubleshooting guide in the user manual. In case of complex problems, contact GE’s technical support team for assistance.

Maintenance recommendations: Regularly inspect the DS200TBQDG1AFF for any signs of physical damage, such as cracks on the board or loose connections. Clean the board gently to remove dust and debris that could affect its performance. Use appropriate testing equipment to check the functionality of the test points and the integrity of the input/output signals. If any issues are detected, such as abnormal signal readings or communication problems, refer to the troubleshooting guide in the user manual. In case of complex problems, contact GE’s technical support team for assistance.

Product Guarantee

GE stands firmly behind the quality of the DS200TBQDG1AFF. The product undergoes rigorous quality control during the manufacturing process to meet high – industry standards. GE offers a standard warranty on the DS200TBQDG1AFF, covering any defects in materials or workmanship. In the unlikely event of a product failure within the warranty period, GE will provide prompt repair or replacement services. Their dedicated technical support team is available around the clock to assist customers with installation, configuration, and any technical issues that may arise. This comprehensive product guarantee reflects GE’s confidence in the DS200TBQDG1AFF and commitment to ensuring customer satisfaction and long – term reliable operation in industrial applications.