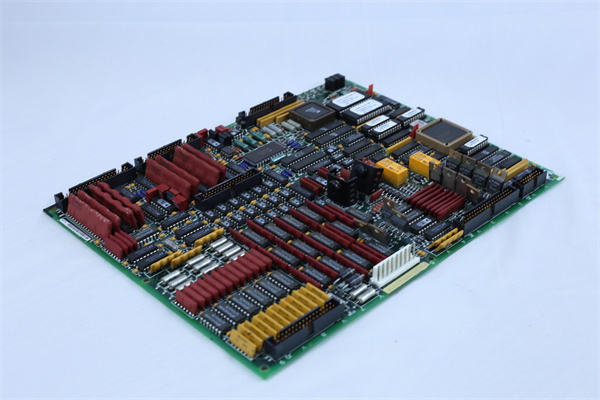

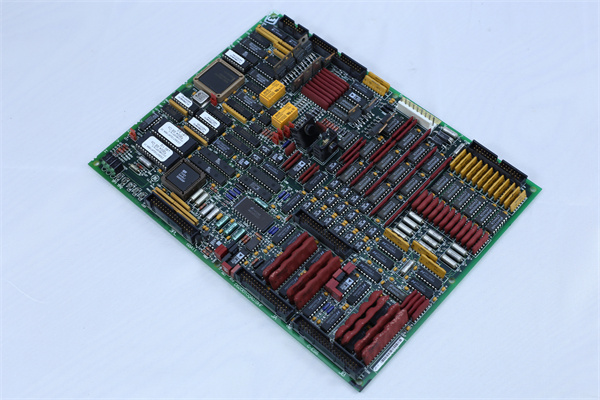

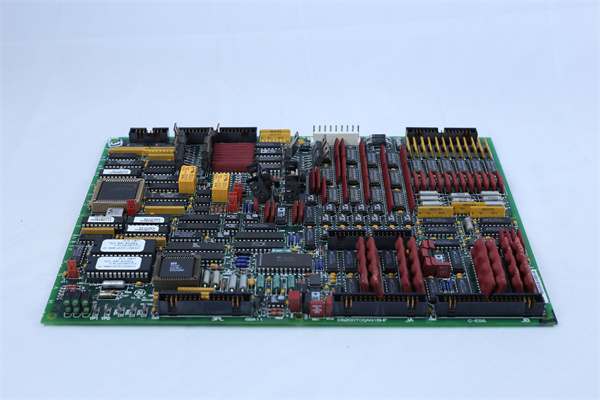

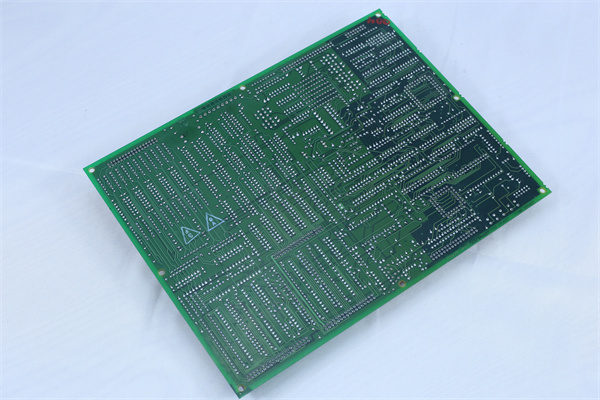

Description

Product Overview

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | DS200TCQAG1BHF |

| Manufacturer | General Electric |

| Product Type | Analog I/O Board |

| Series | Mark V |

| Connector Types | Four 34 – pin connectors, two 40 – pin connectors |

| Jumper Quantity | Six jumpers |

| LED Quantity | Six LEDs |

| Mounting Holes | Six holes for mounting in the drive’s board cabinet |

| Operating Voltage | [Check product manual for exact value, likely in the range of common industrial voltages] |

| Physical Dimensions | [Approximate values: Length – 220mm, Width – 350mm, Height – 25mm] |

| Weight | Approximately 2.2 kg |

| Communication Protocols | Compatible with protocols relevant to the Mark V system (details in product manual) |

| Assembly Type | Normal assembly |

| Protective Coating Style | Normal coating |

| 1st Functional Revision | B |

| 2nd Functional Revision | H |

| Artwork Revision | F |

DS200TCQAG1BHF

Main Features and Advantages

Integrated Diagnostic LEDs: The six LEDs on the DS200TCQAG1BHF serve as a convenient diagnostic tool. They can quickly indicate the operational status of the board, such as power – on, signal reception, and communication link integrity. This feature allows maintenance personnel to quickly identify any potential issues, reducing downtime and enabling prompt troubleshooting.

Application Field

Industrial Manufacturing: In manufacturing plants, the board plays a vital role in controlling production processes. It can interface with sensors on machinery to monitor variables like vibration, position, and force. Based on the processed analog signals, it can trigger actuators to adjust machine settings, ensuring the quality of products and the smooth operation of the production line.

Process Control Industries: Industries such as chemical plants, oil refineries, and water treatment facilities rely on the DS200TCQAG1BHF for process control. It can manage analog signals related to chemical reactions, fluid flow, and water quality parameters. This allows for precise control of processes, maintaining product quality, and ensuring compliance with safety and environmental regulations.

Related Products

DS200TCQCG1BHF: An analog I/O expander board in the Mark V series. It is used to expand the analog I/O capabilities of the system, often working in tandem with the DS200TCQAG1BHF to handle a larger number of analog signals in more complex setups.

DS200DSFBG1A: Another board within the GE product range. While the DS200TCQAG1BHF focuses on analog I/O functions, the DS200DSFBG1A may have different functions, such as digital signal processing or communication interface management, but can be part of an integrated control system with the DS200TCQAG1BHF.

DS200DSPAG1AAB: A board that could be related in terms of system integration. It might handle specific data processing tasks related to the overall control system where the DS200TCQAG1BHF is also installed, working together to achieve seamless control operations.

IC200PWR101: A power supply module. It is essential for providing the necessary power to the DS200TCQAG1BHF and other components in the control system, ensuring stable operation.

DS200TCEAG1BTF: A different type of board, perhaps with specialized functions like turbine control in emergency situations. It can complement the DS200TCQAG1BHF in a comprehensive turbine control setup.

DS200TCQAG1BHF

Installation and Maintenance

Maintenance recommendations: Regularly clean the DS200TCQAG1BHF to remove dust and debris, as these can affect its performance over time. Check the status of the LEDs periodically to monitor the board’s operational health. Inspect the connection points of the connectors to ensure they are secure and free from corrosion. If any issues are detected, such as incorrect signal readings or communication failures, refer to the detailed product manual provided by GE for troubleshooting steps. It’s also advisable to keep spare parts on hand in case a replacement is needed.