Description

Product Overview

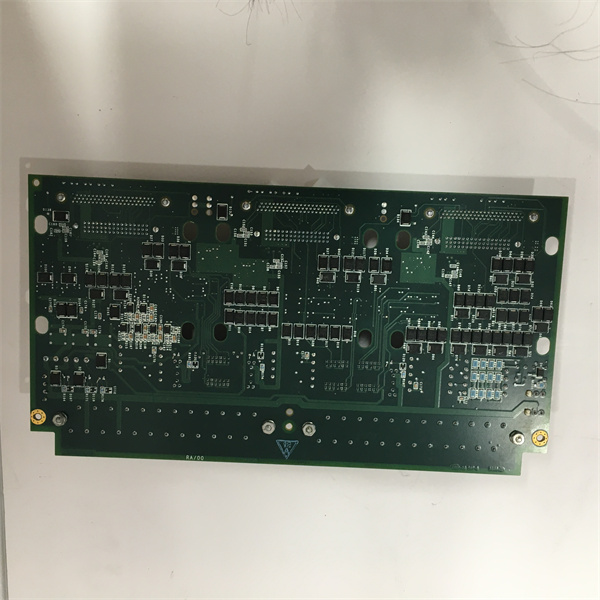

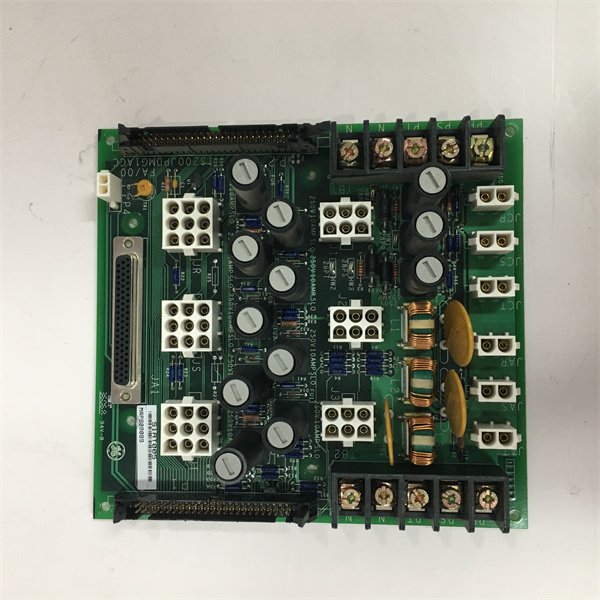

The GE ENK32 is a high – performance control module designed for industrial automation systems. It belongs to GE’s high – performance series of industrial control products, occupying an important position in the field of industrial automation. This module is engineered to provide reliable and efficient control solutions for a variety of industrial applications, including manufacturing, oil & gas, and power generation industries. It offers powerful processing capabilities and precise measurement technology, enabling accurate monitoring and effective control of industrial processes. With its advanced design, the GE ENK32 can seamlessly integrate with existing industrial automation systems, enhancing overall system performance and reliability.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | ENK32 |

| Manufacturer | General Electric |

| Product Type | Control Module |

| Input Voltage Range | 100 – 240 VAC |

| Output Current | Up to 2 A |

| Operating Temperature Range | – 20 °C to + 60 °C |

| Communication Protocol | Modbus TCP/IP, Modbus RTU/ASCII |

| Dimensions | 10 x 15 x 5 cm |

| Weight | 0.5 kg |

| Digital Outputs | 8 |

| Analog Inputs | 16 |

VMICPCI-7632-03310 IS215UCCAH3A 350-657362-003310J

Main Features and Advantages

Reliable and stable: The GE ENK32 is constructed with high – quality materials and advanced manufacturing processes, ensuring high stability and reliability. It can operate stably in harsh industrial environments, withstanding factors such as humidity and dust.

Powerful functionality: It is equipped with 8 digital outputs and 16 analog inputs, which can handle a variety of input and output signals, meeting the diverse needs of different industrial applications. In addition, it supports multiple communication protocols, facilitating easy integration with other devices and systems.

Compact and space – saving: With its compact size and lightweight design, the module can be easily installed in confined spaces without sacrificing functionality or performance, which is especially suitable for space – constrained environments.

User – friendly: The module features an intuitive design and a user – friendly interface, which simplifies installation, setup, and monitoring processes, reducing the workload of operators and being accessible to technicians of all skill levels.

Powerful functionality: It is equipped with 8 digital outputs and 16 analog inputs, which can handle a variety of input and output signals, meeting the diverse needs of different industrial applications. In addition, it supports multiple communication protocols, facilitating easy integration with other devices and systems.

Compact and space – saving: With its compact size and lightweight design, the module can be easily installed in confined spaces without sacrificing functionality or performance, which is especially suitable for space – constrained environments.

User – friendly: The module features an intuitive design and a user – friendly interface, which simplifies installation, setup, and monitoring processes, reducing the workload of operators and being accessible to technicians of all skill levels.

Application Field

The GE ENK32 is widely used in various industrial fields. In the manufacturing industry, it can be used for the control and monitoring of production lines, such as the precise control of robotic arms and the monitoring of conveyor belt speeds. In the oil & gas industry, it plays a crucial role in the control systems of oil extraction platforms and refineries, ensuring the safe and efficient operation of equipment. In the power generation industry, it is used in power plants to monitor and control the operation of generators, boilers, and other equipment. Moreover, it can also be applied in other process industries like chemical and metallurgical industries, helping to improve production efficiency, product quality, and system reliability. Overall, wherever precise control and reliable monitoring are required in industrial automation systems, the GE ENK32 can be a valuable choice.

IS200AEPAH1ACB

Related Products

- GE IC693CPU331: It is a central processing unit module in GE’s PLC system, which works with the ENK32 module to complete the overall control of the system. The CPU331 is responsible for processing and executing control programs, while the ENK32 focuses on input and output signal processing and communication.

- GE IC697ACC722B: This is an analog input/output module. It can be used in conjunction with the ENK32 to expand the analog signal processing capabilities of the system, enabling more precise control and monitoring of analog – related industrial processes.

- GE DS200ADGIH1AAA: It is a digital input module. It can be connected to the ENK32 to increase the number of digital input channels in the system, which is suitable for applications that require a large number of digital signal inputs.

- GE IS220PDIAH1B: It is a power – supply – related module that provides stable power for the ENK32 and other modules in the system, ensuring the normal operation of the entire control system.

- GE IC660ELB912: It is an Ethernet communication module. Similar to the ENK32 in terms of communication function, but may have different application scenarios and performance characteristics. It can be selected according to specific system requirements to achieve efficient data communication within the industrial automation system.

Installation and Maintenance

Pre – installation preparation: Before installing the GE ENK32, make sure the installation environment meets the requirements, with a suitable temperature range from – 20 °C to + 60 °C and low humidity. Check the power supply to ensure that the input voltage is within the range of 100 – 240 VAC. Also, prepare the necessary tools and ensure that the installation location has enough space for the module.

Maintenance recommendations: Regularly check the operating status of the GE ENK32, including the indicator lights and communication connections. Clean the module regularly to remove dust and dirt. When problems occur, refer to the product manual for troubleshooting or contact GE’s professional technical support. It is recommended to perform software upgrades regularly to ensure that the module can adapt to the latest system requirements and improve performance and stability.

Maintenance recommendations: Regularly check the operating status of the GE ENK32, including the indicator lights and communication connections. Clean the module regularly to remove dust and dirt. When problems occur, refer to the product manual for troubleshooting or contact GE’s professional technical support. It is recommended to perform software upgrades regularly to ensure that the module can adapt to the latest system requirements and improve performance and stability.

Product Guarantee

GE stands behind the quality of the ENK32 with a comprehensive product guarantee. The company offers a certain – period quality assurance to ensure that the GE ENK32 is free from defects in materials and workmanship. In case of any quality problems during the warranty period, GE will provide free repair or replacement services. Additionally, GE provides professional after – sales service and technical support. Customers can get timely help and guidance from GE’s technical team when they encounter problems, ensuring the normal operation of the product and giving customers confidence in using the GE ENK32 module.