Description

Product Overview

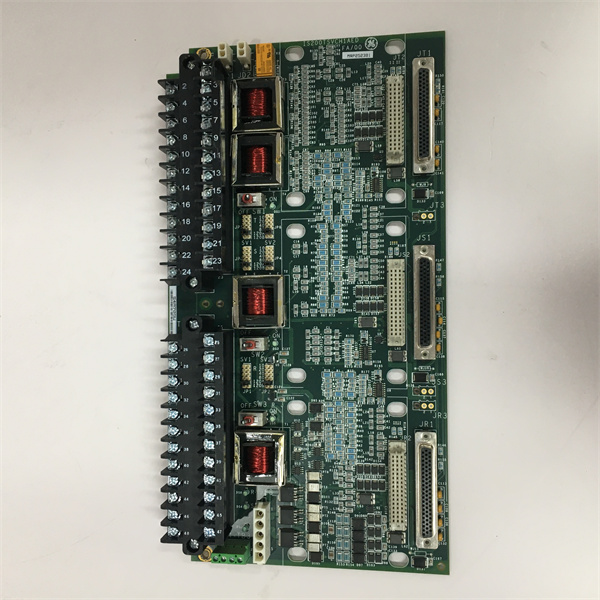

The GE H200I is a high – performance industrial control module designed for advanced automation systems. It belongs to the H200 series, which is known for its reliability and high – precision control capabilities. This module is engineered to meet the demanding needs of various industrial settings, such as manufacturing and process control environments.

With a robust design, the GE H200I offers excellent stability and can operate continuously in harsh conditions. It features an advanced digital signal processor that ensures accurate and consistent control outputs, enabling precise regulation of industrial processes. The module also supports a wide operating voltage range of 220 V and provides a stable output frequency of 50 kHz, making it suitable for different industrial applications. In addition, its ISO 9001 certification guarantees high – quality standards and performance consistency.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | H200I |

| Manufacturer | GE |

| Product Type | Control Module |

| Operating Voltage | 220 V |

| Output Frequency | 50 kHz |

| Certification | ISO 9001 |

| Series | H200 |

| Dimensions | 8×18.6×26.1 cm |

| Weight | 1.14 kg |

| Communication Protocol | Supports common industrial protocols |

| Installation Method | Panel – mountable or rack – mountable |

| Working Temperature | – 10℃ to 55℃ |

| Humidity Range | 5% – 95% non – condensing |

Main Features and Advantages

Reliable and stable: The GE H200I is built with high – quality materials and has a robust construction, which enables it to withstand harsh industrial environments and operate continuously without performance degradation. Its advanced design and excellent heat – dissipation performance ensure stable operation even under high – load conditions.

High – precision control: Equipped with an advanced digital signal processor, the H200I can provide accurate and consistent control outputs, meeting the high – precision control requirements of industrial processes. It can precisely regulate various parameters such as temperature, pressure, and flow rate.

User – friendly interface: This module features a user – friendly interface that simplifies installation and operation. Professionals with different levels of expertise can easily configure and maintain the device, reducing the difficulty of use and improving work efficiency.

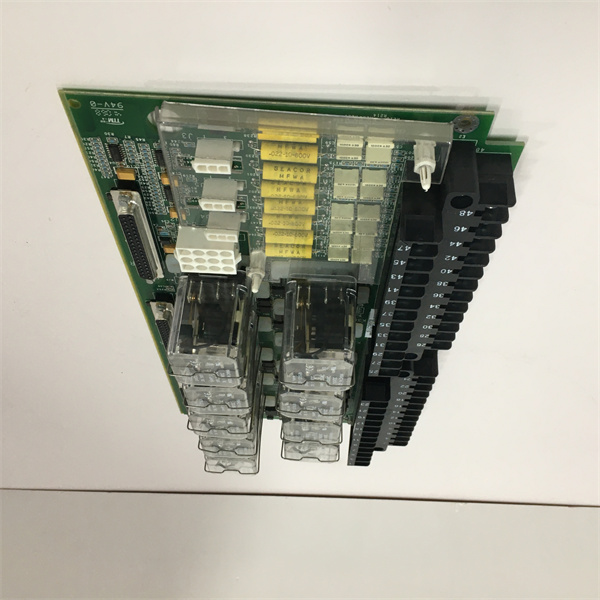

Flexible and scalable: The modular design of the GE H200I allows for easy customization and expansion. It can be easily integrated into existing automation systems and can be upgraded or expanded according to the evolving needs of the production process, providing strong support for the development and transformation of enterprises.

Application Field

The GE H200I has a wide range of applications in various industrial fields. In the manufacturing industry, it is used in production lines to control the operation of machines and equipment, improve production efficiency and product quality. For example, in the automotive manufacturing industry, it can be used to control the assembly process of automobile parts and the operation of robotic arms.

In the process control field, the H200I is suitable for controlling continuous production processes such as chemical, petroleum, and power generation. It can monitor and adjust process parameters in real – time to ensure the stability and safety of the production process. For instance, in a chemical plant, it can be used to control the reaction temperature, pressure, and raw material flow rate to ensure the smooth progress of chemical reactions.

In addition, the GE H200I can also be applied to other industrial fields such as metallurgy, paper – making, and food processing. It can help enterprises improve automation levels, reduce labor costs, and enhance market competitiveness.

IS415UCVGH1A V7666-111000

Related Products

- H200II: The upgraded version of the H200 series, with improved performance and more functions, suitable for more complex industrial automation scenarios.

- H100I: A product in the same series but with different performance parameters and functions. It is mainly used in some industrial occasions with lower requirements, providing a more cost – effective solution.

- GE CABP: The control component backplane is designed to be connected to the H200I, providing a communication interface for other components.

- GE BICH: The H – bridge interface and control board, which works with the H200I to realize the input and output of signals and the control of related equipment.

- GE FOSB: The fiber – optic interface board, most of the input and output of the bridge interface and control board are routed through the sub – components on the H200I to this board to realize long – distance and high – speed data transmission.

Installation and Maintenance

Pre – installation preparation: Before installing the GE H200I, make sure to check the installation environment. The installation location should be dry, well – ventilated, and free from strong electromagnetic interference. At the same time, check whether the power supply voltage is within the specified range of the module to ensure the normal operation of the device. Read the installation manual carefully to understand the installation steps and precautions.

Maintenance recommendations: Regularly clean the surface of the GE H200I to prevent dust and dirt from affecting its heat dissipation and performance. Check the connection of each interface regularly to ensure reliable contact. Monitor the operating status of the module in real – time. If any abnormal situation is found, such as over – temperature, abnormal noise, or incorrect output, stop using it immediately and contact professional technicians for maintenance.

Product Guarantee

GE provides a high – quality guarantee for the H200I. The product is covered by a one – year quality warranty from the date of purchase. During the warranty period, if there is any non – human – caused damage or failure, GE will provide free repair or replacement services. In addition, GE also provides professional technical support and after – sales service. Customers can consult GE’s technical team for any questions or problems that arise during use, and GE will respond in a timely manner to help customers solve problems and ensure the normal operation of the product.