Description

Product Overview

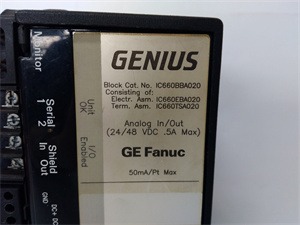

The GE IC660BBA020 is an analog I/O block in the GE Fanuc Genius I/O series, now part of Emerson Automation. It is a high – performance module designed for industrial automation systems. This module serves as a crucial interface between field devices and the control system, enabling the conversion and transmission of analog signals. With its 4 analog inputs and 2 analog outputs, the IC660BBA020 can handle a variety of signal types, including voltages from 0 – 10 VDC, – 10 to + 10 VDC, – 5 to + 5 VDC, 0 – 5 VDC, and currents from 4 – 20 mA (or 1 – 5 VDC). It offers 12 – bit resolution, ensuring accurate signal conversion, and has a fast update rate of 4 ms, allowing for real – time data processing. The module is powered by 24/48 VDC and supports the Genius communication protocol, making it suitable for use as a stand – alone remote I/O module in distributed control systems.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | IC660BBA020 |

| Manufacturer | General Electric |

| Product Type | Analog I/O Block |

| Rated Voltage | 24/48 VDC |

| Input Range | 0 – 10 VDC, – 10 to + 10 VDC, – 5 to + 5 VDC, 0 – 5 VDC, 4 – 20 mA |

| Output Range | 0 – 10 VDC, – 10 to + 10 VDC, – 5 to + 5 VDC, 0 – 5 VDC, 4 – 20 mA |

| Operating Voltage | 18 – 56 VDC |

| Points per Common | One group of 4 inputs and one group of 2 outputs |

| Input Resolution | 12 – bit + sign |

| Output Resolution | 12 – bit + sign |

| Update Frequency | Once every 4 ms |

| Input Filter Ranges | None, 8, 16, 32, 64, 128, 256, 512, 1024 ms |

| Output Load | Voltage mode: ≥ 2000 Ω; Current mode: 0 – 300 Ω |

| Operating Temperature | 0 – 60 °C (32 – 140 °F) |

| Storage Temperature | – 40 – 100 °C (- 40 – 212 °F) |

| Humidity | 5% – 95% (non – condensing) |

| Vibration | 5 – 10 Hz, 0.2″ (5.08 mm) displacement; 10 – 200 Hz at 1 g |

IC660BBA020

Main Features and Advantages

The GE IC660BBA020 offers several notable features and advantages. It provides independent scaling for each input and output, allowing for precise customization to meet specific application requirements. Fault reports can be enabled or disabled for individual input and output channels, enhancing the module’s diagnostic capabilities. The selectable input filter time, which can be set up to 1024 ms, helps to reduce noise and improve signal quality. Each input can operate in normal analog input mode or report only its alarm status, providing flexibility in monitoring and control. Additionally, the module offers low and high alarm limits for each input, as well as power – up default values for each output. It also has the ability to hold the last state or default if CPU communications are lost, ensuring the stability and reliability of the system.

Application Field

The GE IC660BBA020 is widely used in various industrial automation applications. In manufacturing plants, it can be used to monitor and control process variables such as temperature, pressure, and flow. For example, in a chemical processing plant, the module can be used to measure the temperature and pressure of a reaction vessel and send the data to a central control system for analysis and control. In power generation facilities, it can be used to monitor the voltage and current of generators and transformers, ensuring the safe and efficient operation of the power grid. In addition, the module is also suitable for use in water treatment plants, oil and gas production facilities, and other industrial fields where analog signal monitoring and control are required. Its high – speed update rate and accurate signal conversion make it an ideal choice for applications that require real – time data processing and precise control.

Related Products

- IC660BBA100: Similar to the IC660BBA020, it is also an analog I/O block in the GE Fanuc Genius I/O series, but may have some differences in configuration or performance.

- IC660TSA020: This is another model in the Genius I/O series, which may have different terminal arrangements or signal processing capabilities compared to the IC660BBA020.

- IC660EBA020: It belongs to the same family of products, but may have different functions or features, such as different power supply options or communication interfaces.

- IC693/IC695/IC697/IC698/IC200: These are CPU modules, communication modules, and analog – digital modules in the GE series, which can be used in combination with the IC660BBA020 to form a complete industrial control system.

- IC66HHM500/IC66HHM501: Handheld monitors that are compatible with the IC660BBA020. The HHM500 is directly compatible, while the HHM501 requires a configuration change.

IC660BBA020

Installation and Maintenance

Pre – installation preparation: Before installing the GE IC660BBA020, make sure the power supply is within the rated voltage range of 18 – 56 VDC. Check the wiring connections to ensure that the terminals are properly connected and that there are no short circuits or open circuits. Also, make sure the installation environment meets the requirements of the module, with an operating temperature of 0 – 60 °C and a humidity of 5% – 95% non – condensing.

Maintenance recommendations: Regularly check the operating status of the IC660BBA020 through the I/O enabled and unit OK LEDs. If any fault messages are displayed, refer to the troubleshooting guide in the product manual to identify and resolve the problem. Clean the module regularly to prevent dust and dirt from accumulating, which could affect its performance. Additionally, check the wiring connections periodically to ensure they are secure.

Product Guarantee

GE provides a comprehensive product guarantee for the IC660BBA020. The company ensures high – quality products, standing behind the reliability and performance of the module. In case of any quality issues, customers can rely on GE’s after – sales service commitment for timely support and solutions. Technical support is also available to assist customers with installation, configuration, and troubleshooting. This comprehensive guarantee gives customers the confidence that their investment in the IC660BBA020 is protected, ensuring smooth operation and long – term use in industrial automation applications.