Description

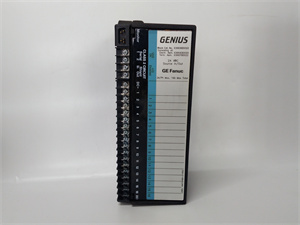

Product Overview

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | IC660BBD022 |

| Manufacturer | General Electric |

| Product Type | Digital Input Module |

| Number of Input Points | 16 |

| Input Voltage | 24V DC |

| Input Current | 8 mA per point |

| Input Logic | Sinking |

| Response Time | ≤ 1 ms |

| Operating Temperature | – 40°C to + 85°C |

| Storage Temperature | – 40°C to + 100°C |

| Dimensions | 22.44 cm x 8.89 cm x 10.00 cm |

| Weight | 4 lbs |

| Communication Protocol | Genius Protocol |

IC660BBD022

Main Features and Advantages

High – speed response: The GE IC660BBD022 boasts an incredibly fast response time of ≤ 1 ms. This rapid response ensures that the control system receives up – to – date information about the status of field devices in real – time. In high – speed industrial processes, such as those in automated assembly lines or high – speed packaging machines, this feature is crucial for maintaining precise control and preventing errors.

Reliable performance in harsh environments: With an operating temperature range from – 40°C to + 85°C and a storage temperature range from – 40°C to + 100°C, the module can withstand extreme temperatures. It is also designed to resist electrical noise, vibrations, and dust, making it suitable for use in a wide variety of industrial settings, including mines, steel mills, and outdoor facilities.

Flexible configuration: The module has 16 input points, which can be configured to suit different application requirements. This flexibility allows it to be used in a diverse range of industrial applications, from simple monitoring tasks to complex control systems. Additionally, the sinking input logic provides compatibility with a wide range of field devices.

Genius Protocol compatibility: The IC660BBD022 supports the Genius Protocol, which enables seamless communication with other devices in the GE Genius I/O system. This protocol ensures reliable and efficient data transfer, allowing for easy integration into existing industrial control networks.

IC660BBD022

Application Field

Automotive industry: In automotive manufacturing, the module is employed to monitor various processes, such as the stamping, welding, and painting operations. It can detect the presence of parts on the assembly line, the position of welding guns, and the status of paint sprayers. By providing accurate real – time data, the IC660BBD022 helps to improve the quality and efficiency of automotive production.

Food and beverage industry: In this industry, the module is used to monitor the operation of food processing and packaging equipment. It can detect the level of ingredients in storage tanks, the status of filling machines, and the position of packaging materials. This ensures that the food and beverage products are produced and packaged in a hygienic and efficient manner.

Related Products

- GE IC660BBD012: A similar digital input module in the same series, but with a different number of input points. It may be more suitable for applications where fewer input signals need to be monitored.

- GE IC660BBD032: Another related digital input module that might offer additional features or a different input voltage range. It could be used in applications where specific input requirements need to be met.

- GE IC661BBD022: A digital output module that can be used in conjunction with the IC660BBD022 to form a complete input – output control system. It is designed to send control signals to actuators based on the input signals received by the IC660BBD022.

- GE IC660BBD023: An upgraded version of the IC660BBD022 with enhanced performance or new features. It can be a good choice for applications that require higher – level functionality.

- GE Genius I/O communication modules: These modules are used to enable communication between the IC660BBD022 and other devices in the industrial network. They support the Genius Protocol and can expand the communication capabilities of the module.

Installation and Maintenance

Maintenance recommendations: Regularly inspect the GE IC660BBD022 for any signs of damage or wear. Check the status of the input signals and the communication with the control system. Clean the module periodically to remove dust and debris. If any faults are detected, refer to the troubleshooting section of the product manual or contact GE’s technical support team for assistance. Keep the module’s firmware up – to – date to ensure optimal performance.