Description

Product Overview

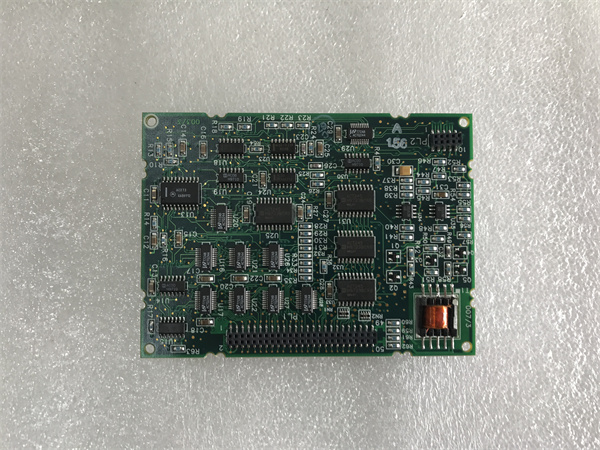

The GE IC660ELB912G is a MicroGENI daughterboard designed by General Electric for use within the Genius I/O systems. This board is an integral part of industrial control setups, acting as a crucial interface that enables seamless communication between the Programmable Logic Controller (PLC) and a wide range of I/O devices such as sensors, switches, and actuators. As a component of the Genius I/O ecosystem, the IC660ELB912G is engineered to offer reliable and efficient data transfer, which is essential for the smooth operation of industrial control systems. With its ability to support up to 30 devices per daughter card, it provides great flexibility in system expansion. The GE IC660ELB912G supports standard baud rates of 38.4 k, 76.8 k, 153.6 k, as well as an extended rate of 153.6 k, catering to diverse industrial applications where different communication speeds are required. This compact and rugged daughterboard is easy to install, allowing for seamless integration into existing control systems, thus enhancing the performance of industrial automation and control processes.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | IC660ELB912G |

| Manufacturer | General Electric |

| Product Type | Daughterboard for Genius I/O systems |

| Power Requirement | 5 volts DC, 400 milliamps |

| Supported Devices | 30 per daughtercard |

| Communication Rates | 38.4 k, 76.8 k, 153.6 k standard, or 153.6 k extended baud rates |

| Input Signal Range | 0 – 20 mA |

| Output Signal Range | 4 – 20 mA |

| Input Response Time | 1 ms |

| Output Response Time | 1 ms |

| Operating Temperature | -20 to 60 °C |

| Dimensions | 4.0″ x 1.0″ x 5.0″ (10.2 cm x 2.5 cm x 12.7 cm) |

IC660ELB912G

Main Features and Advantages

The GE IC660ELB912G stands out for several reasons. Firstly, its high – speed communication capabilities, with support for multiple baud rates, ensure rapid and reliable data transfer between the PLC and I/O devices. This is crucial in industrial environments where timely data exchange is essential for efficient process control. Secondly, the ability to support up to 30 devices per daughter card provides excellent expandability. This means that industrial control systems can be scaled up easily as the production requirements grow or more complex monitoring and control tasks are added. The modular design of the IC660ELB912G also makes it convenient for installation and replacement of components. In case of a component failure, maintenance teams can quickly swap out the affected part, reducing system downtime and associated costs. Additionally, its compact size allows for space – saving installation in control cabinets, which is a significant advantage in facilities where space is at a premium. Finally, being compliant with international standards like UL, CE, RoHS, FCC, and CSA, the GE IC660ELB912G offers assurance of quality and safety in its operation.

Application Field

The GE IC660ELB912G finds wide – ranging applications across various industrial sectors. In the manufacturing industry, it plays a pivotal role in connecting production line equipment. For example, it can link robots, conveyors, and sensors to the control system. By doing so, it enables precise control over the production process, ensuring that products are manufactured with high accuracy and efficiency. In the process control industry, such as in chemical plants or refineries, the IC660ELB912G is used to monitor and control critical process parameters like temperature, pressure, and flow. It helps maintain the stability and reliability of these processes, preventing any potential disruptions that could lead to safety hazards or product quality issues. In the power industry, it is deployed in power generation equipment and power distribution systems. Here, it facilitates the monitoring and control of power generation and power supply processes, ensuring a stable and consistent power output. Moreover, industries like oil and gas, chemical, and water treatment also benefit from the GE IC660ELB912G. In oil and gas, it can be used to monitor pipelines and wellheads, while in water treatment plants, it helps control the water treatment process to ensure clean and safe water supply.

IC660ELB912G

Related Products

- GE DS215UCVBG3A: This might be an I/O module that can work in tandem with the IC660ELB912G to expand the overall I/O capabilities of the system. It could offer additional input or output channels, or different types of interfaces to connect with a wider range of devices.

- GE DS200UCVAG1A: It likely has similar functions to the IC660ELB912G but might have different parameter settings. For instance, it could support a different number of devices or operate at different baud rates, providing users with an alternative option depending on their specific application needs.

- GE IC600CB500A: An intelligent platform component that can be integrated with the IC660ELB912G in an overall control system. It may be involved in more complex control tasks, such as data processing and decision – making based on the data received through the IC660ELB912G.

- GE IS220PRTDH1A: A process control module. It can collaborate with the IC660ELB912G in scenarios where both temperature monitoring (function of IS220PRTDH1A) and I/O communication (function of IC660ELB912G) are required for comprehensive process control.

- GE IS420UCSCH2A: May be related to signal processing and transmission within the control system. It can work in conjunction with the IC660ELB912G to enhance the overall performance of the system, perhaps by optimizing the communication signals or providing additional signal conditioning functions.

Installation and Maintenance

Pre – installation preparation: Before installing the GE IC660ELB912G, it is essential to power off all relevant equipment to avoid any electrical hazards. Check the installation environment to ensure it meets the specified temperature range of -20 to 60 °C and is free from strong electromagnetic interference. Gather all the necessary tools and installation accessories, and carefully review the installation manual. When installing, make sure to leave a minimum of 1/8 ″ space between the modules to allow for proper airflow, which is crucial for cooling.

Maintenance recommendations: Regularly inspect the GE IC660ELB912G for any signs of loose connections. Ensure that all cables are firmly attached to prevent signal disruptions. Clean the module’s surface periodically to remove dust and dirt, as these can affect heat dissipation and overall performance, especially in dusty industrial environments. Continuously monitor the module’s operating status. If any abnormal indicators or malfunctions are detected, promptly refer to the manual for troubleshooting steps or contact professional technical support.

Maintenance recommendations: Regularly inspect the GE IC660ELB912G for any signs of loose connections. Ensure that all cables are firmly attached to prevent signal disruptions. Clean the module’s surface periodically to remove dust and dirt, as these can affect heat dissipation and overall performance, especially in dusty industrial environments. Continuously monitor the module’s operating status. If any abnormal indicators or malfunctions are detected, promptly refer to the manual for troubleshooting steps or contact professional technical support.

Product Guarantee

GE offers a comprehensive product guarantee for the GE IC660ELB912G. The product comes with a one – year warranty, during which GE will replace or repair the product free of charge in case of any quality – related issues. The company’s global technical support team is always available to assist customers. Whether it’s providing guidance during the installation process, helping with system integration, or troubleshooting operational problems, GE’s technical experts are committed to ensuring the optimal performance of the IC660ELB912G. With strict quality control measures implemented during production, GE has full confidence in the reliability of this daughterboard. This product guarantee not only reflects GE’s trust in its product but also its dedication to achieving high levels of customer satisfaction in the industrial automation market.