Description

Product Overview

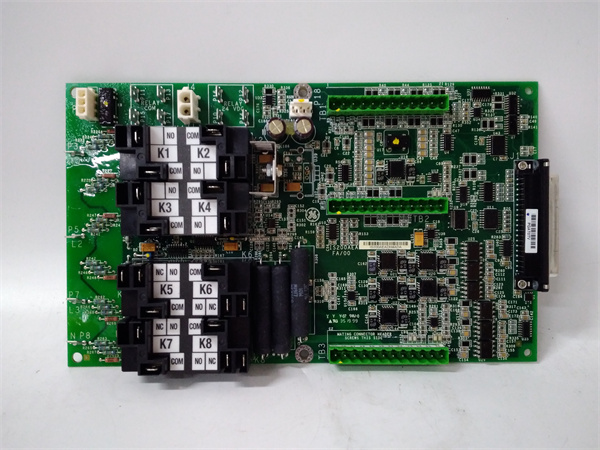

The GE IS200AEADH4ADA is a high – performance analog input/output (AIO) board by GE, designed specifically for the Mark VI turbine control system. As a crucial component in this system, it plays a pivotal role in ensuring the efficient and reliable operation of gas turbines. This board is engineered to precisely measure and control various turbine parameters, which is essential for maintaining the optimal performance of the turbine.

With its advanced design, the GE IS200AEADH4ADA can interface directly with a wide range of sensors and actuators related to the turbine. It enables real – time monitoring of critical factors such as fuel supply, ignition, rotational speed, temperature, and pressure. By providing accurate data and control signals, it helps in making sure the gas turbine operates smoothly under different conditions. Whether it’s in a power generation plant or an industrial process that relies on gas turbines, this board contributes significantly to the overall stability and safety of the operation.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | IS200AEADH4ADA |

| Manufacturer | GE |

| Product Type | Analog Input/Output Board for Turbine Control |

| Input Voltage Range | [Specify if available, not found in given data] |

| Output Voltage Range | [Specify if available, not found in given data] |

| Temperature Rating | 30 °C – 65 °C |

| Size | 17.8 cm wide x 33.02 cm high |

| Number of Relay Channels | 12 |

| Series | Drive Control (associated with Mark VI turbine control system) |

| Communication Interfaces | Multiple (for data exchange with other systems, details not given) |

| Input/Output Signal Types | Analog and digital (capable of handling signals from various sensors and actuators) |

| Installation Type | [Details on how it’s installed in the system, not given] |

| Weight | 1000g |

IS200AEADH4ADA

Main Features and Advantages

The GE IS200AEADH4ADA offers several distinct features and advantages. Its ability to precisely measure and control multiple turbine parameters is a key strength. For example, it can accurately monitor the fuel supply to ensure the turbine is running on an optimal fuel – air ratio, which not only maximizes efficiency but also reduces emissions.

The board has a high – quality construction and is designed to withstand the harsh environments often found in industrial settings. With a temperature rating of 30 °C – 65 °C, it can operate reliably even in areas with significant temperature fluctuations. Additionally, its 12 relay channels provide versatility in controlling different devices associated with the turbine system. These relay channels can handle a variety of loads, making it suitable for a wide range of applications within the turbine control setup.

Moreover, the GE IS200AEADH4ADA supports multiple communication interfaces. This allows for seamless integration with other control systems, data acquisition devices, and monitoring systems. It can easily exchange data, enabling centralized control and monitoring of the gas turbine operation. This connectivity feature also makes it possible to implement advanced control strategies and perform in – depth data analysis for predictive maintenance, enhancing the overall lifespan and performance of the turbine.

Application Field

The GE IS200AEADH4ADA is predominantly used in power generation facilities where gas turbines are a core component. In large – scale power plants, it monitors and controls the gas turbines that generate electricity. By precisely regulating parameters like fuel flow and rotational speed, it ensures the turbines produce a stable and consistent power output. This is crucial for maintaining grid stability and meeting the electricity demands of consumers.

It also finds applications in industrial processes that rely on gas turbines for mechanical power. For instance, in oil and gas refineries, gas turbines are used to drive compressors and pumps. The GE IS200AEADH4ADA board helps in controlling these turbines, ensuring the efficient operation of the refinery’s production processes. In manufacturing plants that use gas – fired heating systems with turbine – driven blowers, this board can regulate the turbines to maintain the desired temperature and air circulation, optimizing the manufacturing process. Overall, wherever gas turbines are used, the GE IS200AEADH4ADA plays an essential role in ensuring their safe, stable, and efficient operation.

IS200AEADH4ADA

Related Products

- GE IS200AEPCH1BAA: Likely part of the same Mark VI turbine control system family. It may have complementary functions, perhaps focusing more on a different aspect of turbine control, such as a specific type of signal processing or control algorithm implementation compared to the GE IS200AEADH4ADA which is mainly an AIO board.

- GE IS200DS: Could be a data storage or data – handling module related to the turbine control system. It might work in tandem with the GE IS200AEADH4ADA to store the data collected from the sensors connected to the AIO board, enabling historical data analysis for performance evaluation and troubleshooting.

- GE IS200TPROH1BBB: This could be a terminal protection – related component. It may protect the connections and interfaces of the GE IS200AEADH4ADA board, safeguarding it from electrical surges or short – circuits, thus enhancing the overall reliability of the system.

- GE IS215VCMIH2CA: Another board within the GE industrial control product range. It may have similar applications in industrial control systems, but perhaps with different input/output capabilities or targeted at a different subset of industrial processes compared to the GE IS200AEADH4ADA which is centered around gas turbine control.

- GE IS210WSVOH1AE: A single – channel servo I/O terminal board. While its function is more focused on servo control and sensor interface for specific applications like turbine servo – based systems, it can be used in combination with the GE IS200AEADH4ADA in a more complex gas turbine control setup, where both analog I/O and servo – related control are required.

Installation and Maintenance

Pre – installation preparation: Before installing the GE IS200AEADH4ADA, it is essential to ensure the target system is powered off. Thoroughly inspect the board for any visible signs of damage during transit. Familiarize yourself with the board’s layout, connectors, and pin – outs as described in the product manual. Check the compatibility of the GE IS200AEADH4ADA with other components in the Mark VI turbine control system, including power supply requirements and communication interface settings. Make sure all the sensors and actuators that will be connected to the board are in proper working condition and their specifications match those of the board.

Maintenance recommendations: Regularly monitor the GE IS200AEADH4ADA for any abnormal behavior. Check for any signs of overheating, such as discoloration of components or abnormal fan noise (if applicable). Periodically inspect the connections of all cables to ensure they are secure. Clean the board gently to remove dust and debris, as these can accumulate over time and affect the board’s performance. Keep an eye on the data readings from the sensors connected to the board to detect any anomalies. If any issues arise, refer to the detailed troubleshooting guide in the product manual or contact GE’s technical support for assistance.

Product Guarantee

GE stands firmly behind the quality of the GE IS200AEADH4ADA. The product comes with a comprehensive quality assurance program. During the specified warranty period, if the board is found to have defects in materials or workmanship, GE will provide free repair or replacement services. Their highly skilled technical support team is always available to assist customers. Whether it’s answering installation – related questions, helping with troubleshooting complex issues, or providing advice on optimizing the board’s performance, GE ensures that customers get the best possible service. This commitment to quality and customer satisfaction reflects GE’s confidence in the GE IS200AEADH4ADA and its ability to perform reliably in demanding industrial applications.