Description

Product Overview

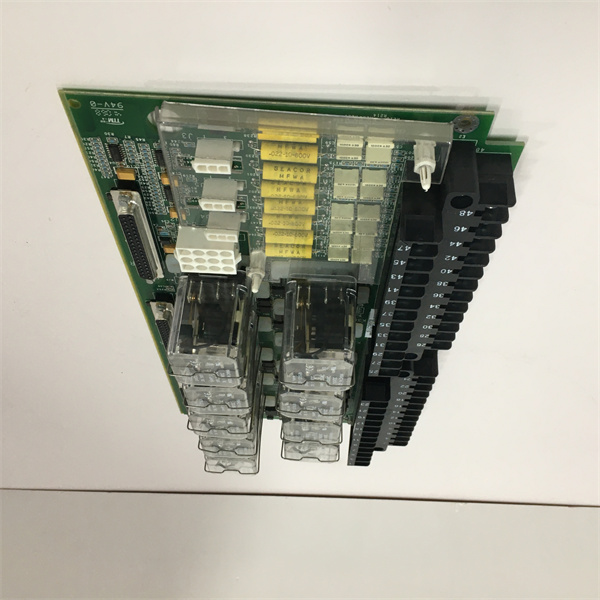

The GE UR6TH is a digital I/O module that belongs to the Multilin family of products, a well – known offering from General Electric. It serves as a critical interface within industrial control systems, playing a pivotal role in establishing connections between GE’s protective relay systems and a wide array of external devices.

This module is engineered to provide highly flexible I/O options. It effectively expands the system’s capacity for handling digital signals, enabling seamless connections to various external components such as pushbuttons, indicator lights, or external relays. With features like isolated inputs and outputs, the UR6TH ensures reliable signal transmission, safeguarding the system from electrical interference that is common in industrial settings. Additionally, it supports multiple communication protocols, including Modbus, DNP 3, and IEC 61850. This multi – protocol support allows for its seamless integration with different control and monitoring systems, making it a versatile choice for diverse industrial applications. Whether in power generation, transmission, or distribution, or in industrial automation and control systems, the GE UR6TH proves to be an essential component for efficient system operation.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | UR6TH |

| Manufacturer | General Electric |

| Product Type | Digital I/O Module |

| Inputs | 8 contact inputs |

| Outputs | 4 form – A (unmonitored) outputs |

| Input Voltage Range | 24 – 250 VAC/DC |

| Output Voltage Range | 0 – 10 VDC |

| Operating Temperature Range | – 40 °C to 70 °C |

| Dimensions | Length: ~7 inches, Width: ~6 inches, Height: ~1.5 inches |

| Weight | ~2 pounds 9 ounces (1.16 kg) |

| Communication Protocols | Modbus, DNP 3, IEC 61850 |

| Isolation | Inputs and outputs are isolated |

| Mounting Type | Suitable for standard industrial panel mounting |

Main Features and Advantages

High – Speed Signal Processing

The GE UR6TH is designed to process digital signals at high speeds. This allows for quick response times in industrial control applications. For example, when connected to sensors in a manufacturing line, it can rapidly detect changes in the production process and send corresponding control signals to actuators. This high – speed processing helps in maintaining smooth and efficient production, reducing the risk of errors and delays.

Versatile Connectivity Options

With 8 contact inputs and 4 form – A (unmonitored) outputs, the UR6TH offers great versatility in connecting to different external devices. The wide input voltage range of 24 – 250 VAC/DC and output voltage range of 0 – 10 VDC make it compatible with a variety of sensors and actuators. This versatility ensures that it can be easily integrated into existing industrial systems without the need for complex voltage conversion mechanisms.

Reliable Signal Isolation

The isolated inputs and outputs of the UR6TH are a key advantage. In industrial environments filled with electrical noise, this isolation feature prevents interference from affecting the signal integrity. It protects the module and the connected systems from voltage spikes and electrical disturbances, ensuring reliable operation over long periods. This reliability is crucial for applications where system downtime can lead to significant losses, such as in power plants or continuous – process manufacturing facilities.

IS220PDIAH1A

Multiple Communication Protocol Support

As mentioned earlier, the support for Modbus, DNP 3, and IEC 61850 communication protocols is a major strength. This enables the UR6TH to communicate with different types of devices and systems. It can interface with other control modules, SCADA systems, or smart grid components, facilitating seamless data exchange and system integration. This multi – protocol compatibility makes it a future – proof solution, adaptable to evolving industrial communication standards.

Application Field

Power Generation Plants

In power generation plants, the GE UR6TH is extensively used. For instance, it can connect various sensors that monitor parameters such as temperature, pressure, and vibration of generators and turbines. The module then sends the processed data to the plant’s control system. In case of any abnormal readings, it can trigger alarms or initiate corrective actions through connected actuators. This helps in ensuring the safe and efficient operation of power – generating equipment, minimizing unplanned outages and optimizing energy production.

Industrial Automation

In manufacturing industries, the UR6TH plays a vital role in automating production lines. It can be connected to pushbuttons used by operators to start or stop production processes, as well as to indicator lights that show the status of different machinery. Additionally, it can interface with robotic arms and conveyor belts, controlling their movements based on the signals received from sensors. This integration of different components through the UR6TH enables smooth and coordinated operation of the entire production line, increasing productivity and product quality.

Power Transmission and Distribution

For power transmission and distribution networks, the UR6TH is used to monitor and control the status of circuit breakers, transformers, and other electrical equipment. It can detect faults in the network, such as overcurrents or short circuits, and send signals to protective relays to isolate the affected sections. By providing real – time data on the health of the power network, it helps utility companies in maintaining grid stability and ensuring reliable power supply to consumers.

Related Products

GE UR6DH

This digital I/O module is part of the same product family as the UR6TH. It has a similar function but may differ in the number of inputs and outputs or the specific communication protocols it emphasizes. It could be a more cost – effective option for applications with less complex I/O requirements.

GE UR9EH

It might be an upgraded version of the UR6TH with enhanced processing capabilities or additional features. For example, it could have a higher – speed processor for even faster signal processing, making it suitable for applications where ultra – rapid response times are crucial.

GE UR8FH

This module could have a different form factor or be optimized for specific industrial environments. It may have better resistance to harsh conditions such as extreme temperatures or high levels of dust, making it more suitable for use in outdoor or industrial settings with challenging operating conditions compared to the UR6TH.

GE URRHH

Designed for high – reliability applications, it may have redundant components or enhanced diagnostic features. In critical systems where continuous operation is essential, like in some aerospace or medical equipment power management systems, the GE URRHH can provide the extra level of reliability that the UR6TH may not offer in such extreme scenarios.

GE UR8NH

With potentially higher accuracy in signal measurement and processing, it can be used in applications where precision is of utmost importance. For example, in scientific research facilities or high – end manufacturing processes that require precise control and monitoring, the GE UR8NH can outperform the UR6TH in terms of measurement accuracy.

Installation and Maintenance

Pre – installation preparation: Before installing the GE UR6TH module, it is crucial to carefully check the compatibility of the module with your existing industrial control system. Ensure that the power supply available meets the input voltage requirements of the UR6TH, which range from 24 – 250 VAC/DC. Measure the physical space in the electrical panel where the module will be installed to ensure a proper fit, as it has dimensions of approximately 7 inches in length, 6 inches in width, and 1.5 inches in height. Clean the installation area thoroughly to prevent any dust or debris from entering the module, as this could affect its performance. Also, verify that all the necessary cables and connectors for the module’s inputs and outputs are in good condition and of the correct type.

Maintenance recommendations: Regularly inspect the GE UR6TH module for any signs of physical damage, such as cracks in the casing or loose connections. Check the input and output signals periodically to ensure they are within the expected ranges. Clean the module gently using a soft, dry cloth to remove any dust that may have accumulated over time, as dust can cause electrical interference. Monitor the operating temperature of the module, as it should remain within the specified range of – 40 °C to 70 °C. If any issues are detected, refer to the product manual for detailed troubleshooting steps. If the problem persists, contact GE’s technical support team for further assistance.

Maintenance recommendations: Regularly inspect the GE UR6TH module for any signs of physical damage, such as cracks in the casing or loose connections. Check the input and output signals periodically to ensure they are within the expected ranges. Clean the module gently using a soft, dry cloth to remove any dust that may have accumulated over time, as dust can cause electrical interference. Monitor the operating temperature of the module, as it should remain within the specified range of – 40 °C to 70 °C. If any issues are detected, refer to the product manual for detailed troubleshooting steps. If the problem persists, contact GE’s technical support team for further assistance.

Product Guarantee

GE stands firmly behind the quality of the UR6TH product. The company ensures that the UR6TH is manufactured using high – quality components and undergoes rigorous testing processes. GE offers a standard one – year warranty for the UR6TH module. This warranty covers any defects in materials or workmanship that may occur during normal use within the warranty period. In case of any product failures during this time, GE’s dedicated after – sales service team is available to provide prompt support. They can assist with troubleshooting, replacement parts, or even on – site repair services if required. GE’s technical support experts are also on – hand to answer any questions related to the installation, configuration, or operation of the UR6TH module, giving customers the confidence that their investment in this product is well – protected.