Description

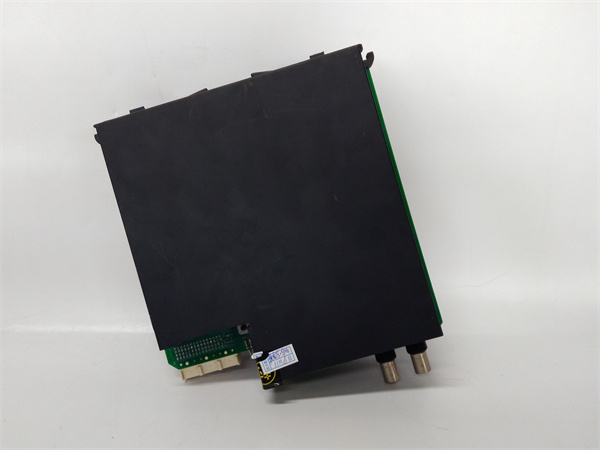

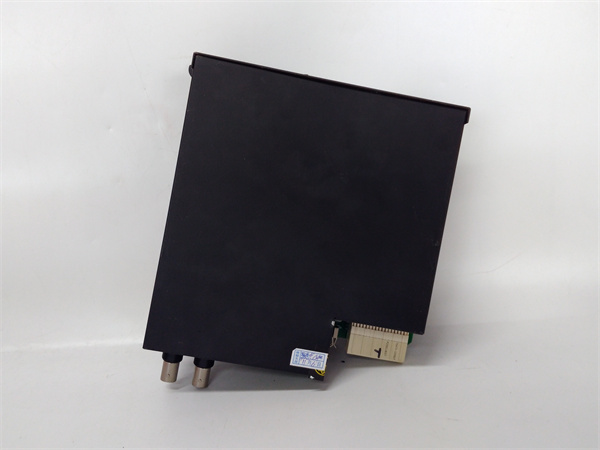

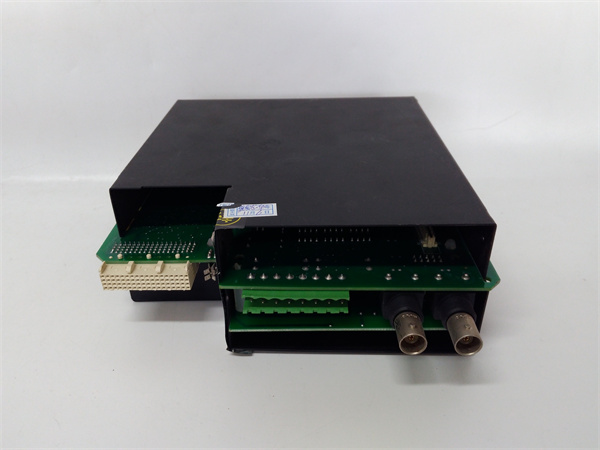

Product Overview

The GE UR9EV is a high – performance industrial control module that plays a pivotal role in various industrial automation setups. As part of GE’s comprehensive portfolio of industrial control products, the UR9EV is designed to offer reliable and precise control solutions. It serves as a crucial component within industrial control systems, functioning as a central processing unit for protective relay systems.

This module is engineered to analyze sensor data in real – time and make critical decisions to safeguard electrical equipment. With its advanced processing capabilities, the UR9EV can efficiently handle complex protection algorithms and relay logic, ensuring the safe and smooth operation of electrical systems. Whether in a large – scale manufacturing plant or a power generation facility, the UR9EV provides the necessary intelligence to manage and protect industrial processes, making it an essential element for modern industrial operations.

Technical Specifications

|

Parameter Name

|

Parameter Value

|

|

Product Model

|

UR9EV

|

|

Manufacturer

|

GE

|

|

Product Type

|

CPU Module (acts as control module in protective relay systems)

|

|

Operating Voltage

|

600 – 1500V AC

|

|

Operating Frequency

|

47 – 63 Hz

|

|

Communication Protocols

|

DNP 3, Modbus, IEC 61850, SEL 334, etc.

|

|

Physical Dimensions

|

Precise measurements for compatibility (size allows for easy integration)

|

|

Operating Temperature

|

– 40 °C to 85 °C

|

|

Relative Humidity

|

5% – 95% non – condensing

|

|

Memory

|

1 GB DDR3 SDRAM

|

|

Processor

|

Dual – core ARM Cortex – A9

|

|

Protection Functions

|

Overcurrent, overvoltage, ground fault protection

|

GE UR9EV

Main Features and Advantages

High – Performance Processing

The UR9EV is equipped with a dual – core ARM Cortex – A9 processor, enabling high – speed and efficient handling of complex protection algorithms and relay logic. This powerful processing core ensures that the module can quickly analyze sensor data and make accurate decisions, even in high – stress industrial environments.

Comprehensive Protection Functions

It offers a wide range of protection functions such as overcurrent, overvoltage, and ground fault protection. These features safeguard electrical equipment from potential damage, minimizing downtime and maintenance costs in industrial operations.

Versatile Communication Capabilities

With support for multiple communication protocols like DNP 3, Modbus, IEC 61850, and SEL 334, the UR9EV can easily network with other devices. This allows for seamless data exchange and system monitoring, enhancing the overall efficiency and connectivity of the industrial control system.

Compact and Durable Design

The module’s compact size makes it suitable for installation in various electrical panels, saving valuable space. Additionally, it is constructed with high – quality materials, ensuring durability and longevity even in harsh industrial conditions.

Application Field

In the power generation industry, the GE UR9EV is extensively used to protect and control power transformers, generators, and motors. It continuously monitors the electrical parameters of these critical components, providing real – time protection against faults and abnormal conditions. This helps in maintaining the stability and reliability of power generation processes, ensuring a consistent power supply.

Within manufacturing plants, the UR9EV plays a crucial role in controlling automated production lines. It coordinates the operation of various machinery and equipment, ensuring that they function smoothly and safely. For example, it can monitor the performance of motors driving conveyor belts, protecting them from overloading and ensuring continuous production flow.

In the oil and gas sector, where reliable operation in harsh environments is essential, the UR9EV is used to control and protect pumping stations, compressors, and other equipment. Its ability to withstand extreme temperatures and operate in high – humidity conditions makes it an ideal choice for this industry, safeguarding the integrity of the oil and gas production and transportation processes.

GE UR9EV

Related Products

- GE UR series universal relays: These are related products in the same family as the UR9EV. They share similar functions of protection and control but may have different levels of complexity and features. Some models in the UR series might be more suitable for smaller – scale applications or have different communication capabilities compared to the UR9EV.

- GE – compatible I/O modules: These modules can be integrated with the UR9EV to expand its functionality. They provide additional input and output channels, allowing the UR9EV to interface with a wider range of sensors and actuators in the industrial field.

- GE software for configuration and programming: This software is designed to work specifically with the UR9EV and other GE industrial control products. It simplifies the process of customizing the module’s settings, programming protection algorithms, and configuring communication protocols, making it easier for engineers to deploy the UR9EV in different applications.

- GE power monitoring devices: These devices can work in tandem with the UR9EV to provide more comprehensive power monitoring capabilities. They can measure and analyze power quality parameters, and the UR9EV can then use this data to make more informed decisions regarding protection and control.

- GE replacement parts for UR9EV: In case of component failures in the UR9EV, these replacement parts are available to ensure quick repairs and minimize downtime. They are designed to be fully compatible with the UR9EV, maintaining its performance and reliability.

Installation and Maintenance

Pre – installation preparation

Before installing the UR9EV module, ensure that the electrical panel where it will be installed is clean and free from dust and debris. Check the power supply to confirm that it meets the specified voltage and frequency requirements of the UR9EV. Also, plan the layout of the module within the panel, considering proper ventilation and access for future maintenance. When handling the UR9EV, use appropriate electrostatic discharge (ESD) protection to prevent damage to the sensitive components.

Maintenance recommendations

Regularly check the status indicators on the UR9EV to monitor its operation. If any abnormal lights are displayed, refer to the product manual for troubleshooting guidance. Periodically update the module’s firmware to benefit from the latest bug fixes and performance improvements provided by GE. Also, clean the module gently to remove any accumulated dust, as this can affect its heat dissipation and overall performance. Conduct routine tests of the protection functions to ensure that the UR9EV is still providing effective protection to the electrical equipment it controls.

Product Guarantee

GE stands firmly behind the quality of the UR9EV industrial control module. The product comes with a comprehensive quality assurance program. GE ensures that each UR9EV is manufactured to the highest industry standards, using top – grade materials and advanced manufacturing processes. In the event of any product – related issues during the warranty period, GE offers prompt and reliable after – sales service. Their team of experienced technical experts is available to provide remote or on – site support. Whether it’s a hardware malfunction or a software – related problem, GE is committed to resolving the issue quickly to minimize disruptions to the customer’s industrial operations. This not only demonstrates GE’s confidence in the quality of the UR9EV but also their dedication to customer satisfaction.