Description

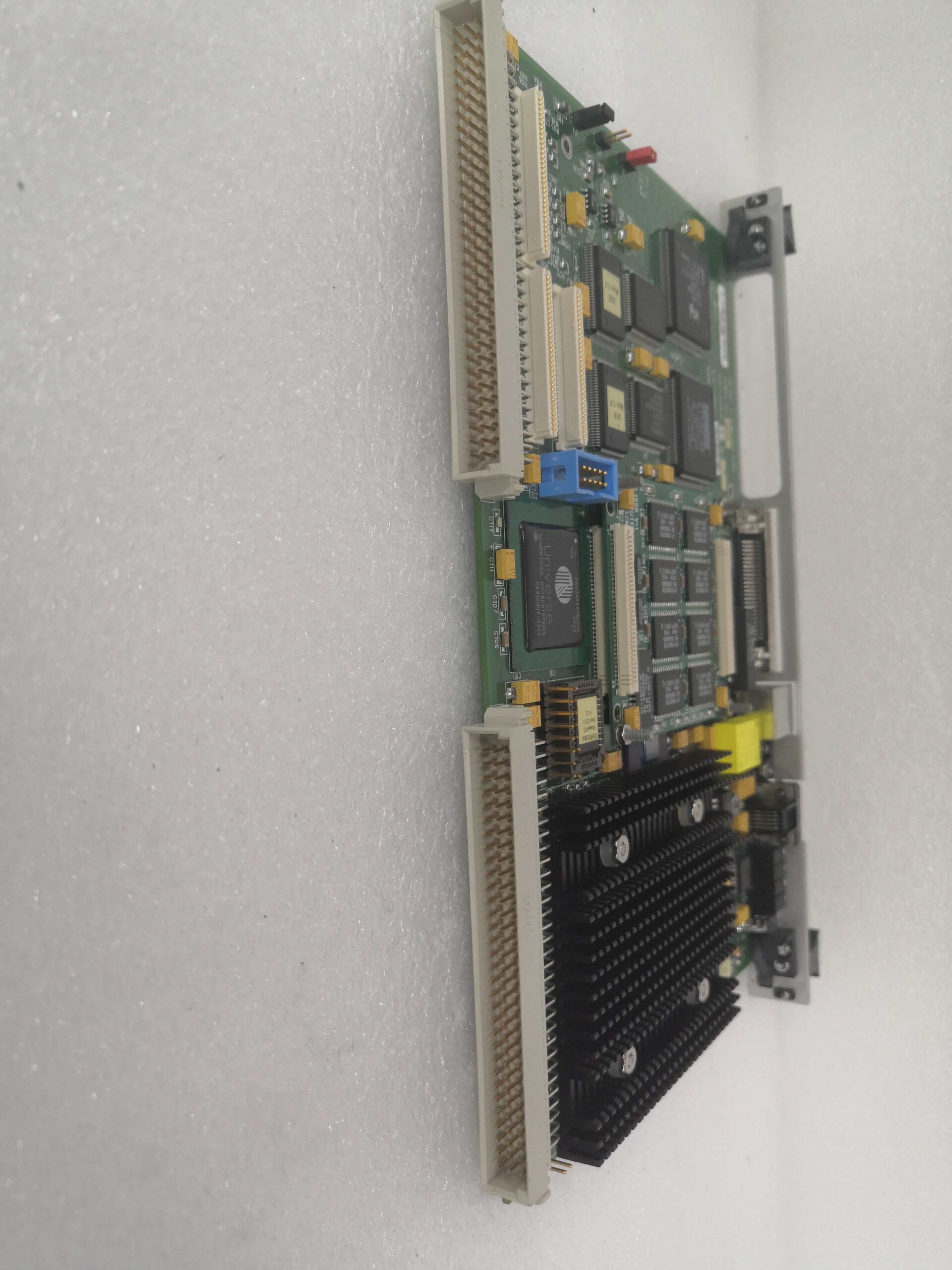

GE Fanuc VMIVME-2540 Intelligent Counter Controller Module

1. Product Description

The GE Fanuc VMIVME-2540 is a high-performance VMEbus slave interface module designed for industrial automation, real-time control, and data acquisition. Engineered by GE Fanuc (now part of Abaco Systems), the VMIVME-2540 excels in high-speed event counting (up to 4 gigaevents), multi-channel digital signal measurement, and signal generation. Its flexible configuration (4/8/16/24 discrete input channels) and robust industrial design make it ideal for demanding environments, including manufacturing, energy, and robotics. Key advantages include precision counting, signal isolation, and compatibility with GE Fanuc VME series single-board computers (SBCs).

2. Product Parameters

| Parameter | Specification |

|---|---|

| Interface | VMEbus slave (6U VME standard) |

| Counting Capacity | Up to 4 gigaevents |

| Channels | 4/8/16/24 programmable discrete input/output channels |

| Output Resolution | 12-bit |

| Voltage Range | ±10V (standard); high-voltage option (600mA sink/source) |

| Signal Isolation | Analog inputs configurable for offline disconnection (external circuit isolation) |

| Compatibility | GE Fanuc VME SBCs (e.g., VMIVME-7591, VMIVME-7698, VMIVME-7740) |

| Physical Dimensions | 6U Eurocard (233.35 mm × 160 mm) |

| Operating Temperature | 0°C to 50°C (operation); -25°C to 60°C (storage) |

| Power Requirements | +5V (2.9A), +3.3V (1.9A), +12V (0.1A) |

VMIVME-2540

3. Advantages and Features

- High-Speed Precision: Counts up to 4 gigaevents with sub-millisecond accuracy, suitable for high-frequency applications (e.g., production line counting).

- Flexible Configuration: Programmable channel options (4/8/16/24) via onboard jumpers, supporting diverse voltage levels.

- Signal Isolation: Disconnects analog inputs from external circuitry for interference-free operation and offline testing.

- Industrial-Grade Reliability: Rugged design with extended temperature range (-25°C to 60°C storage) and IP-rated components (dust/vibration resistance).

- Multi-Protocol Support: Compatible with VMEbus standards and scalable for complex control systems (e.g., PLC integration).

4. Application Areas and Use Cases

- Industry: Manufacturing, energy (power plants), robotics, water treatment, and test systems.

- Scenarios: Event counting (e.g., conveyor belt parts), motion control (robot positioning), and real-time data acquisition.

- Case Study: A automotive assembly line used the VMIVME-2540 to monitor 24 discrete sensors for component placement accuracy. Its 4 gigaevent capacity and 12-bit resolution reduced errors by 98%, improving line efficiency.

5. Competitor Comparison

Compared to similar VMEbus modules, the VMIVME-2540 stands out with:

- Higher Channel Density: Supports up to 24 channels (vs. 16-channel alternatives).

- Extended Counting Range: 4 gigaevent capacity (vs. 1–2 gigaevent limits in legacy models).

- Integrated Isolation: Built-in analog input disconnection (eliminates need for external isolation modules).

- Wide Voltage Range: Optional 600mA high-voltage output (rare in standard counter modules).

VMIVME-2540

6. Selection Recommendations

- Channel Requirements: Choose 4/8/16/24 channels based on sensor/actuator density.

- Environment: Ensure operating temperature (0°C–50°C) matches site conditions; use high-voltage models (600mA) for heavy-duty loads.

- Compatibility: Verify VMEbus SBC compatibility (e.g., GE Fanuc VMIVME series).

- Budget: Balance features (e.g., channel count, isolation) against cost (USD $3,200–$8,900 range).

7. Precautions

-

Installation: Follow ESD (electrostatic discharge) protocols; secure VMEbus connections.

-

Environment: Avoid exposure to moisture/dust; ensure adequate cooling for continuous operation.

-

Maintenance: Schedule annual checks for connector wear; update firmware via GE Fanuc support tools.

-

Voltage Handling: Confirm output current (10mA standard vs. 600mA high-voltage) to prevent overload.

Shanxi Xinyeda International Trade Co., Ltd. is your trusted partner for [GE Fanuc VMIVME-2540] and other automation spare parts. Visit our website www.xydcontrol.com or contact us for sales and technical support.