Description

Product Overview

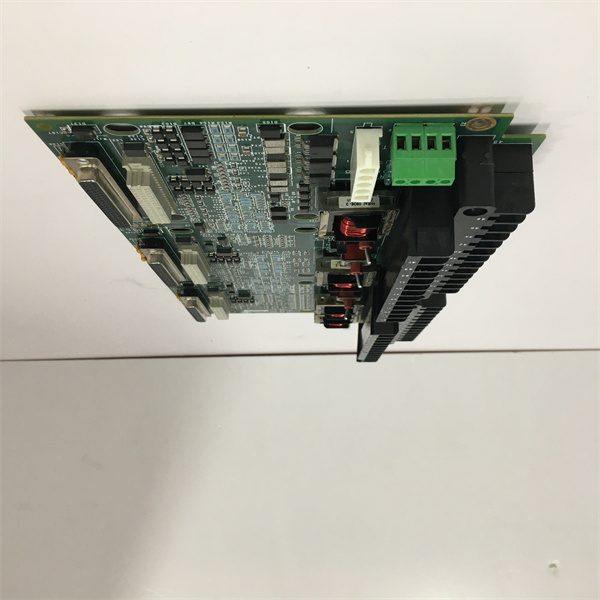

The GE WES13 – 3 is a multifunctional and high – performance module in the industrial automation domain, proudly developed by GE. It serves as a critical component within industrial control systems, playing a central role in ensuring smooth operations.

Functionally, it acts as a nerve center, handling communication, control, and data processing tasks. For instance, it communicates effectively with various input/output (I/O) modules. These I/O modules gather essential data from sensors spread across industrial setups, such as temperature sensors in a chemical plant or proximity sensors in a manufacturing assembly line. The WES13 – 3 then processes this data and sends out appropriate control signals to actuators, like circuit breakers in a power substation or robotic arms in a factory. It’s also designed to be the central hub for monitoring overall system conditions, enabling operators to keep a close eye on the state of industrial processes.

In terms of its series and platform, it is part of GE’s comprehensive range of industrial control products, which are known for their reliability and adaptability. This module is well – positioned for use in a wide array of industrial applications, from small – scale machine control to large – scale process control in industrial complexes. Its value lies in its ability to enhance the efficiency, reliability, and precision of industrial automation systems, ultimately leading to increased productivity and reduced downtime in industrial operations.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | WES13 – 3 |

| Manufacturer | GE |

| Product Type | Field Controller Master Unit Module (suspected based on functionality) |

| Input Voltage | 12 – 24 VDC |

| Memory | 2 MB battery – backed SRAM, 64 MB SDRAM, 16 MB flash memory |

| Communication Ports | Ethernet, RS – 232, RS – 485, Modbus |

| Operating Temperature | – 40 °C to + 70 °C |

| Humidity | 5 – 95% non – condensing |

| Weight | 0.45 kg (0.99 lbs) |

| I/O Expansion | Can support addition of I/O modules (details vary by configuration) |

| Compatibility | Works with GE – related control systems and some third – party compatible devices |

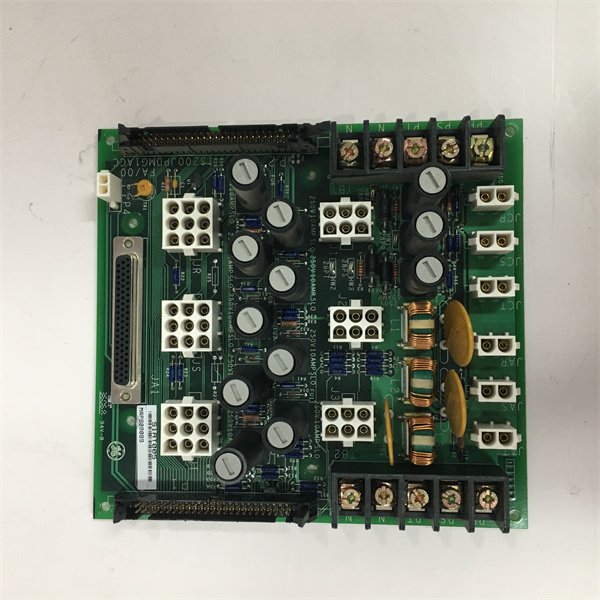

IS200JPDMG1ACC S1AT005

Main Features and Advantages

High – Performance Processing

The GE WES13 – 3 is equipped with a powerful processor that can efficiently handle complex data processing and control tasks. This enables it to quickly analyze data from multiple sensors simultaneously. In a high – speed manufacturing line where numerous sensors are constantly feeding data on product quality, speed, and position, the module can process this data in real – time. It then makes rapid control decisions, ensuring that the production process runs smoothly and any issues are addressed immediately, thus minimizing production errors and waste.

Versatile Communication Capabilities

With multiple communication ports including Ethernet, RS – 232, RS – 485, and support for Modbus protocol, the WES13 – 3 can easily interface with a wide range of devices. This versatility allows it to integrate seamlessly into existing industrial networks. For example, it can communicate with other control modules, 上位机 (host computers), and various field devices. In a large – scale industrial plant with a complex network infrastructure, the module can establish stable communication channels, facilitating the transfer of data and commands across different parts of the system, which is crucial for coordinated operation.

Robust and Reliable Design

Built with industrial – grade components, the GE WES13 – 3 is designed to withstand harsh operating conditions. It can endure temperature fluctuations from extremely cold – 40 °C to hot + 70 °C environments, as well as high humidity levels up to 95% non – condensing. In addition, it is resistant to mechanical vibrations and electromagnetic interference, which are common in industrial settings. In a power generation facility, where there are strong electromagnetic fields and constant vibrations from generators, the module continues to function reliably. Its robust design ensures long – term, trouble – free operation, reducing the need for frequent maintenance and replacement, and ultimately saving costs for industrial users.

IS215WETAH1BB IS200WETAH1AGC

Application Field

Manufacturing Industry

In manufacturing plants, the GE WES13 – 3 is extensively used for machine control. It can manage the operation of conveyor belts, ensuring the smooth movement of products along the production line. For example, it controls the speed and direction of conveyor belts based on the production rate and the position of products detected by sensors. It also plays a crucial role in controlling robotic arms used for tasks like picking and placing components during assembly. By accurately processing sensor data and sending control signals, it enables precise and efficient operation of these manufacturing devices, improving overall production efficiency and product quality.

Power and Energy Sector

In power generation and distribution, the WES13 – 3 is utilized for substation automation. It monitors and controls various aspects of substation equipment. For instance, it receives data from sensors that measure voltage, current, and temperature in transformers. Based on this data, it can send control signals to circuit breakers to protect the substation from overcurrents or abnormal temperatures. In a power grid, where the stable operation of substations is vital for continuous power supply, the GE WES13 – 3 helps in ensuring the reliable and safe operation of these critical infrastructure components.

Process Control in Industries

Industries such as chemical, food and beverage, and pharmaceuticals rely on precise process control. The GE WES13 – 3 is used to monitor and regulate processes in these industries. In a chemical plant, it can control the flow rate of reactants based on temperature and pressure sensor data, ensuring that chemical reactions occur under optimal conditions. In a food processing factory, it can manage the speed of filling machines and the temperature of cooking equipment, maintaining product quality and consistency throughout the production process.

Related Products

- GE WES5162 – 9101: Likely part of the same product family, it may have different memory configurations or communication capabilities compared to the WES13 – 3. It could be designed for more specialized applications within industrial control, perhaps with a focus on a particular type of process or a higher – end version for more demanding tasks.

- GE WES5123 – 1200: Another module in the series, it might have distinct features such as different I/O capacities or a different form factor for easier integration in certain setups. It could be optimized for use in smaller – scale industrial systems or those with specific space constraints.

- GE WES5120 5120 – 1106: This product may offer alternative functionality, like enhanced diagnostic features or a different approach to data storage and retrieval. It can be used in parallel with the WES13 – 3 in complex industrial control systems where different aspects of control and monitoring are required.

- GE WESDAC D20ME: It is a different component within the GE industrial control ecosystem. While the WES13 – 3 focuses on overall control and communication, the WESDAC D20ME may be more involved in data acquisition and processing at a lower level, and they can work together to form a complete industrial control solution.

- GE WES5302 – 111: May have its own unique selling points, such as better compatibility with certain types of sensors or actuators. It could be a complementary product to the WES13 – 3, used in situations where specific sensor – actuator interfaces are needed in the industrial control setup.

Installation and Maintenance

Pre – installation preparation: Before installing the GE WES13 – 3, ensure that the installation area is clean, dry, and free from excessive dust and debris. Verify that the power supply voltage matches the module’s requirement of 12 – 24 VDC. Familiarize yourself with the wiring diagrams provided in the product manual to ensure correct connection of communication ports and I/O lines. Check the compatibility of the WES13 – 3 with other components in the control system, such as I/O modules and host computers. Make sure all the necessary tools, like screwdrivers and wire strippers, are readily available for a smooth installation process.

Maintenance recommendations: Regularly inspect the GE WES13 – 3 for any signs of physical damage, such as cracks on the casing or loose connections. Clean the module periodically to remove accumulated dust, as dust can affect its performance and potentially cause overheating. Monitor the temperature of the installation environment to ensure it remains within the specified – 40 °C to + 70 °C range. Check the communication ports for any signs of corrosion or poor connection. If the module has diagnostic indicators, keep an eye on them for any abnormal readings. In case of any issues, refer to the product manual provided by GE for troubleshooting steps or contact their technical support team.

Maintenance recommendations: Regularly inspect the GE WES13 – 3 for any signs of physical damage, such as cracks on the casing or loose connections. Clean the module periodically to remove accumulated dust, as dust can affect its performance and potentially cause overheating. Monitor the temperature of the installation environment to ensure it remains within the specified – 40 °C to + 70 °C range. Check the communication ports for any signs of corrosion or poor connection. If the module has diagnostic indicators, keep an eye on them for any abnormal readings. In case of any issues, refer to the product manual provided by GE for troubleshooting steps or contact their technical support team.

Product Guarantee

GE stands firmly behind the quality of the GE WES13 – 3. The module comes with a comprehensive quality assurance program. In the event of any manufacturing defects within the specified warranty period, GE will provide free repair or replacement services. Their team of highly skilled technical experts is available around the clock to offer support for installation, operation, and any technical queries related to the WES13 – 3. This demonstrates GE’s confidence in the reliability and performance of the product, ensuring that industrial users can rely on it for their critical industrial applications. Whether it’s in a high – speed manufacturing line or a complex power generation system, customers can have peace of mind knowing that GE is committed to the long – term functionality of the GE WES13 – 3.