Description

Product Overview

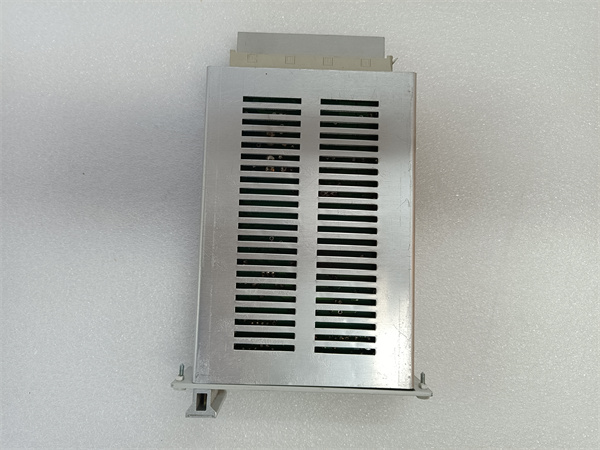

The GE WES5302 – 150 is a high – performance industrial control module by GE, designed to be a linchpin in industrial automation and control systems. This module is engineered to handle a wide array of tasks, making it an essential component for various industrial applications. It serves as a digital quantity control module, adept at processing switching signals, which are crucial for indicating the state of devices or systems, such as on/off or running/stopping status. By continuously monitoring these signal changes, the GE WES5302 – 150 can accurately grasp the real – time operating status of equipment and systems.

It also performs logical operations on received signals. For instance, based on pre – set logic conditions, it can trigger corresponding control actions like starting or stopping a device or adjusting its running state. In addition, the module supports multiple communication interfaces and protocols, enabling seamless data exchange and cooperation with other control systems or devices. This allows for easy integration into broader automation networks, facilitating information sharing and centralized management, thereby enhancing the overall efficiency and reliability of the industrial control setup.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | WES5302 – 150 |

| Manufacturer | GE |

| Product Type | Digital Quantity Control Module |

| Input Voltage Range | 90 – 265 VAC |

| Output Voltage Range | 24 VDC |

| Operating Temperature Range | – 25 °C to + 70 °C |

| Storage Temperature Range | – 40 °C to + 85 °C |

| Humidity Range | 5 % – 95 % (non – condensing) |

| Communication Protocol | Modbus RTU/TCP |

| Control Outputs | 4 x Relay Outputs |

| Analog Inputs | 8 x 0 – 10V or 4 – 20 mA Inputs |

| Power Consumption | Max 20W |

| Dimensions | 175 mm x 90mm x 75mm |

| Weight | 1.5 kg |

GE WES5302-150

Main Features and Advantages

The GE WES5302 – 150 boasts several remarkable features. Its wide input voltage range of 90 – 265 VAC makes it highly adaptable to different electrical setups across various industrial environments. This adaptability reduces the need for complex voltage conversion systems, simplifying installation and maintenance.

The module’s 4 relay outputs provide reliable control over external devices. These outputs can handle a significant load, ensuring stable operation even when controlling power – hungry components such as large motors or solenoid valves. The 8 analog inputs, which can accept signals in the range of 0 – 10V or 4 – 20 mA, enable precise monitoring of process variables. This is crucial for applications where accurate measurement of parameters like temperature, pressure, or flow rate is essential for maintaining product quality and process efficiency.

Moreover, its support for Modbus RTU/TCP communication protocol is a major advantage. Modbus is one of the most widely used industrial communication protocols, and the GE WES5302 – 150‘s compatibility with it allows for seamless integration with other Modbus – enabled devices in the industrial network. This ease of integration promotes interoperability, enabling the module to work harmoniously with a wide range of sensors, actuators, and control systems, ultimately enhancing the overall functionality of the industrial automation system.

Application Field

The GE WES5302 – 150 finds extensive applications in multiple industries. In manufacturing plants, it plays a vital role in controlling production lines. For example, it can monitor the status of conveyor belts through digital inputs, and use its relay outputs to control motors that start or stop the conveyor operation. In a food and beverage factory, the module’s analog inputs can be connected to sensors measuring the filling level of bottles or the temperature of the production process. Based on these measurements, the GE WES5302 – 150 can adjust the speed of filling machines or the heating/cooling systems, ensuring product consistency and quality.

In power generation facilities, this module is used to control and monitor electrical equipment. It can receive digital signals from circuit breakers indicating their open or closed status and use its outputs to remotely operate these breakers if necessary. The analog inputs can be used to measure electrical parameters such as voltage and current, enabling the module to detect any anomalies in the power system and take corrective actions.

Water treatment plants also benefit from the GE WES5302 – 150. It can control the opening and closing of valves based on the water level sensors (connected via analog inputs) and the status of pumps (monitored through digital inputs). This helps in optimizing the water treatment process, ensuring a continuous and clean water supply.

GE WES5302-150

Related Products

- GE WES5302: A related product in the same series, likely sharing some core features with the GE WES5302 – 150. It may have a different configuration in terms of input/output capabilities or communication options, perhaps being more suitable for less complex applications or different industrial sectors.

- GE IC3603A282A: A regulator invertor assembly, which may be used in conjunction with the GE WES5302 – 150 in power – related control systems. It can help in regulating and inverting power, ensuring stable power supply for the module and other connected devices.

- GE IC3603A285A: A source selecter assembly. This can be used to select different signal or power sources for the GE WES5302 – 150, providing flexibility in system design and operation, especially in scenarios where multiple input sources need to be managed.

- GE IC3603A290A: A rectifier filter assembly. It plays a role in rectifying and filtering power, which is crucial for providing clean and stable power to the GE WES5302 – 150, protecting it from power fluctuations and ensuring reliable operation.

- GE IC3603A291A: A rectifier isolater assembly. This product is likely used to isolate the rectified power, adding an extra layer of protection to the GE WES5302 – 150 and the overall system, safeguarding against electrical interference and potential damage.

Installation and Maintenance

Pre – installation preparation: Before installing the GE WES5302 – 150, carefully check the input voltage requirements to ensure they match the available power supply. Inspect the module for any visible damage during transit. Familiarize yourself with the wiring diagrams provided in the product manual. Clean the installation area to prevent dust or debris from affecting the module’s performance. Make sure all the devices that will be connected to the GE WES5302 – 150, such as sensors and actuators, are in proper working condition and their specifications are compatible with the module.

Maintenance recommendations: Regularly monitor the GE WES5302 – 150 for any abnormal behavior, such as overheating, incorrect outputs, or communication errors. Check the connections of all cables and wires to ensure they are secure. Clean the module periodically to remove dust that may accumulate over time, as dust can cause overheating and affect performance. Keep an eye on the power supply to ensure it remains stable. If any issues arise, refer to the troubleshooting section of the product manual or contact GE’s technical support for assistance.

Product Guarantee

GE stands firmly behind the quality of the GE WES5302 – 150. The product comes with a comprehensive quality assurance program. During the specified warranty period, if the module is found to have defects in materials or workmanship, GE will provide free repair or replacement services. Their technical support team is readily available to assist customers with any installation – related queries, troubleshooting, and advice on optimizing the module’s performance. GE’s commitment to product quality and customer satisfaction is evident in their prompt response to customer issues, ensuring that the GE WES5302 – 150 continues to operate reliably and efficiently, contributing to the seamless functioning of industrial control systems.