Description

Product Overview

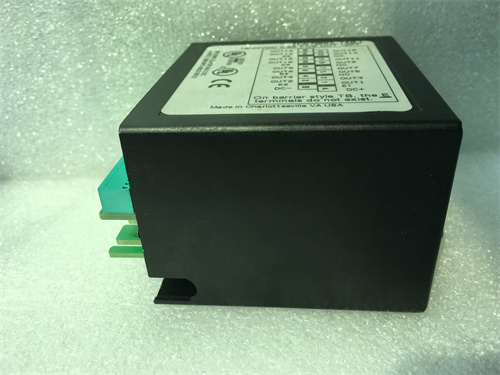

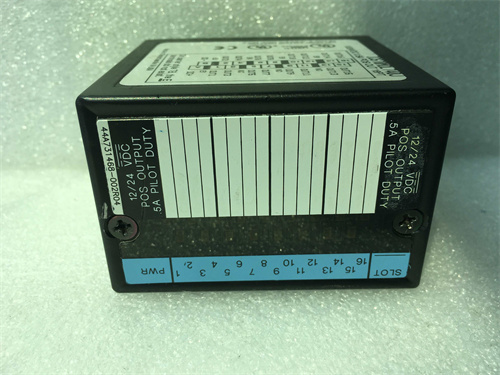

The GE IC670MDL740 is a high – performance discrete output module that plays a crucial role in industrial automation systems. As part of the GE Fanuc’s offerings, it is designed to meet the demanding requirements of various industrial control applications. This 16 – channel module serves as a reliable interface between control systems and actuators, ensuring seamless communication and efficient operation.

With its positive logic output design, the IC670MDL740 is well – suited for powering a wide range of output devices. Whether it’s illuminating indicator lights, energizing relay coils, or driving solenoid – based equipment with low – rated currents, this module can handle the task with ease. Its ability to operate within a voltage range of 9.2 to 29.5 volts DC makes it highly versatile, adaptable to different power supply conditions commonly found in industrial settings.

Technical Specifications

|

Parameter Name

|

Parameter Value

|

|

Product Model

|

IC670MDL740

|

|

Manufacturer

|

General Electric

|

|

Product Type

|

Discrete Output Module

|

|

Series

|

Field Control

|

|

Number of Channels

|

16

|

|

Output Voltage Range

|

9.2 – 29.5 VDC

|

|

Output Voltage Type

|

DC

|

|

Module Circuit Type

|

Sourcing

|

|

User Output Current per Point

|

0.5 A

|

|

Total Output Current per Module

|

4 A

|

|

Current Consumption from BIU Power

|

111 mA

|

|

Surge Current Rating

|

2 A (for 100 ms max)

|

|

Minimum Load Current per Point

|

1 mA

|

|

Output Voltage Drop

|

0.5 V

|

|

Output Leakage Current at 0 VDC

|

5 – 30 mA

|

|

Typical Response Time for Signal Transitions

|

–

|

|

Integrated Wiring Terminals

|

25 – terminal

|

|

Status Indication

|

Separate LED for each output channel’s on/off state, LED for fuse – blown status

|

|

Operating Voltage (mentioned in some sources)

|

220 V (but main operating range is 9.2 – 29.5 VDC for output)

|

|

Output Frequency

|

50 kHz

|

IC670MDL740

Main Features and Advantages

High – Density Output

Featuring 16 output channels, the GE IC670MDL740 offers high – density output capabilities. This allows for the control of multiple devices from a single module, reducing the need for additional modules and thus saving space in control panels. It simplifies the overall system architecture and wiring, making installation and maintenance more efficient.

Wide Voltage Compatibility

The ability to operate over a wide voltage range of 9.2 to 29.5 VDC is a significant advantage. It can be easily integrated into existing industrial systems with different power supply configurations without the need for complex voltage conversion setups. This flexibility makes it suitable for a diverse range of applications, from small – scale industrial setups to large – scale manufacturing plants.

Precise Output Control

With a user – output current of 0.5 A per point and a total of 4 A per module, the IC670MDL740 provides precise control over the power delivered to each output device. This ensures that the connected actuators receive the appropriate amount of power, optimizing their performance and lifespan. The module also has a relatively low output voltage drop of 0.5 V, minimizing power losses during operation.

Robust Design

Built with durability in mind, the GE IC670MDL740 is constructed using high – quality materials that can withstand the harsh conditions of industrial environments. It is designed to resist electrical surges, vibrations, and temperature variations, ensuring reliable operation over an extended period. The module also features advanced protective circuits to safeguard against over – current situations, protecting both the module and the connected devices.

Easy Monitoring

The presence of separate status LEDs for each output channel and an LED for fuse – blown status makes it easy for operators to monitor the module’s operation. At a glance, they can determine whether an output is active or if there is a problem with the fuse, enabling quick troubleshooting and minimizing downtime.

IC670MDL740

Application Field

Manufacturing

In manufacturing plants, the GE IC670MDL740 is used to control a variety of equipment. For example, in an automotive assembly line, it can power the indicator lights that signal the status of different workstations. It can also control the solenoid – driven valves that regulate the flow of hydraulic fluids in machinery, ensuring smooth and accurate operation of the assembly process. In a food and beverage manufacturing facility, the module can be used to control the motors that drive conveyor belts, ensuring the proper movement of products through the production line.

Building Automation

For building automation systems, the IC670MDL740 plays a crucial role. It can control the relays that switch on and off lighting systems in different areas of a building, based on programmed schedules or sensor inputs. It can also be used to operate the solenoid – controlled dampers in HVAC systems, regulating the flow of air and maintaining comfortable indoor conditions. In a large commercial building, the module can manage multiple such functions, contributing to energy – efficient and convenient building operation.

Industrial Machinery Control

In industrial machinery, such as packaging machines and printing presses, the GE IC670MDL740 is used to control various actuators. In a packaging machine, it can control the motors that feed packaging materials, the solenoids that seal the packages, and the sensors that detect the presence of products. In a printing press, it can control the relays that operate the ink – dispensing mechanisms and the motors that move the printing plates, ensuring high – quality and consistent printing output.

Related Products

- GE Fanuc PLC Systems: The IC670MDL740 is designed to be integrated with GE Fanuc’s PLC systems. These PLCs provide the overall control logic for the industrial process, while the IC670MDL740 is responsible for the discrete output functions. Different models of GE Fanuc PLCs, such as those in the Series 90 – 30 or Series 90 – 70, can be paired with the IC670MDL740 depending on the complexity and scale of the application.

- Other GE I/O Modules: GE offers a range of other input/output modules. For example, input modules like the IC670MDL640 (a 16 – point discrete input module) can be used in conjunction with the IC670MDL740. The input module can receive signals from sensors and switches, and the IC670MDL740 can then use these signals to control the output devices, creating a complete control loop.

- GE Power Supplies: To power the IC670MDL740 and the associated control system, GE provides suitable power supplies. These power supplies are designed to deliver stable power within the voltage range required by the module, ensuring reliable operation. The choice of power supply depends on factors such as the power consumption of the module and other components in the system.

- Actuators and Output Devices: The IC670MDL740 is designed to drive various actuators and output devices. This includes indicator lights, relay coils, solenoid – based equipment, and motors. Different types and models of these devices can be connected to the module, depending on the specific application requirements. For example, high – brightness LED indicator lights can be used for better visibility in a noisy industrial environment, while high – torque solenoids can be used to operate heavy – duty valves.

- Communication Modules: In an industrial automation setup, communication modules are often required to enable the IC670MDL740 to communicate with other devices or a central control station. GE offers communication modules that support protocols such as Modbus, Ethernet/IP, or Profibus. These modules can be integrated with the system to allow for remote monitoring and control of the IC670MDL740 and the overall industrial process.

Installation and Maintenance

Pre – installation preparation: Before installing the GE IC670MDL740, ensure that the installation area is clean, dry, and free from excessive dust and electromagnetic interference. Verify the compatibility of the module with the existing control system, especially the PLC and power supply. Check the power supply voltage to ensure it falls within the range of 9.2 – 29.5 VDC. Use appropriate tools to carefully mount the module in the designated slot of the control panel or rack. Connect the 25 – terminal integrated wiring terminals correctly, following the wiring diagram provided in the product manual. Make sure to use proper grounding techniques to protect against electrical hazards.

Maintenance recommendations: Regularly inspect the IC670MDL740 for any signs of physical damage, such as cracks in the casing or loose connections. Monitor the status LEDs to quickly identify any abnormal conditions, such as a blown fuse or a malfunctioning output channel. Clean the module periodically to remove dust and debris that could affect its performance. Check the output voltage and current regularly to ensure they are within the specified limits. In case of any issues, refer to the detailed user manual provided by GE for troubleshooting steps. If the problem persists, contact GE’s technical support team for further assistance. Periodically update the firmware of the module, if available, to ensure it has the latest features and performance improvements.

Product Guarantee

General Electric offers a comprehensive product guarantee for the GE IC670MDL740. The product undergoes strict quality control during manufacturing to meet the highest industry standards. GE provides a standard warranty period, during which any defects in materials or workmanship will be rectified free of charge. Their technical support team is available to assist customers with installation, configuration, and any technical issues that may arise during the product’s lifespan. Whether it’s a query about the module’s wiring, output control, or troubleshooting a performance problem, GE’s experts are committed to ensuring that the IC670MDL740 operates smoothly, providing customers with confidence in their investment in industrial automation solutions.