Description

Product Overview

The GE IC695ALG508-AA is a highly specialized analog input module, an integral part of the PACSystems RX3i family. Initially developed by GE Intelligent Platforms and now under Emerson Automation, this module is designed to precisely support the input of resistance temperature detector (RTD) signals. It serves as a crucial component in industrial automation and process control systems where accurate temperature measurement is of utmost importance. With its advanced features, the IC695ALG508-AA can directly interface with RTD sensors, making it an ideal choice for applications that demand high – precision temperature monitoring. In an industrial setup, it plays a key role in ensuring the stable operation of various processes by providing reliable temperature data to the overall control system.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | IC695ALG508-AA |

| Manufacturer | Emerson Automation (formerly GE Intelligent Platforms) |

| Product Type | Analog Input Module (RTD Input) |

| Number of Channels | 8 isolated, differential input channels |

| Supported RTD Sensor Types | Platinum 385/391.6, Nickel 618/672, Nickel – Iron 518, Copper 426; also supports various Pt100, Pt1000 and other RTDs with different accuracy levels and temperature ranges |

| Temperature Measurement Range | Generally – 200 °C to + 850 °C (depends on the RTD sensor used) |

| Accuracy and Resolution | Usually 16 – bit resolution for high – precision temperature measurement |

| Resistance Input Range | Accepts direct resistance inputs from 0 – 260 ohms to 0 – 4200 ohms |

| Power Dissipation | Maximum 2.5 W |

| Internal Power | 3.3V @ 400 mA; 5.1V @ 200 mA |

| Humidity | 5 – 95 %, non – condensing |

| Hot – swap Capability | Yes, allows removal and insertion under power (RIUP) for uninterrupted system operation |

| Data Format | Configurable as 16 – bit integer or 32 – bit real number |

| Data Units | Configurable for °C, °F, or ohms |

| Fault Monitoring | Includes watchdog, RAM fail, and flash fail statuses |

| Dimensions | Approx. 200 × 150 × 20 mm |

| Weight | 1.8 kg |

| Country of Origin | United States |

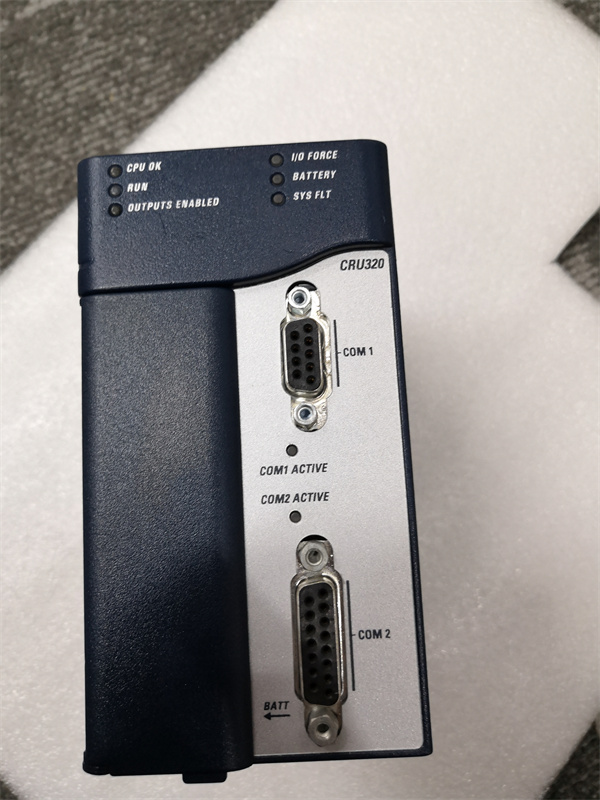

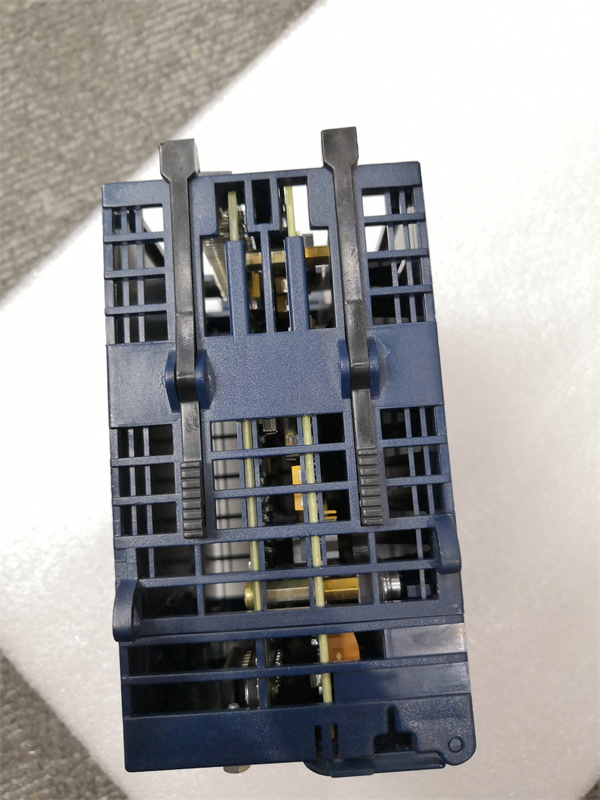

IC695CPU315-BB

Main Features and Advantages

Wide Compatibility: The IC695ALG508-AA supports a diverse range of RTD sensor types, including platinum, nickel, nickel – iron, and copper RTDs such as platinum 385/391.6, nickel 618/672, nickel – iron 518, and copper 426. This wide compatibility ensures that it can be used in various industrial applications with different sensor requirements.

Direct Resistance Measurement: It has the ability to accept direct resistance inputs within a wide range from 0 – 260 ohms to 0 – 4200 ohms. This feature enables it to be used not only for temperature measurement via RTDs but also for applications where direct resistance measurement is needed.

Flexible Wiring: The module is compatible with 2 – wire, 3 – wire, or 4 – wire RTD configurations. This flexibility in wiring allows for easy integration into existing systems and different installation scenarios, providing convenience for engineers during the setup process.

Hot – swap Capability: The hot – swap feature of the IC695ALG508-AA is a significant advantage. It allows for the removal and insertion of the module while the system is powered (RIUP). This means that maintenance or replacement of the module can be carried out without shutting down the entire system, minimizing downtime and ensuring continuous operation in critical industrial processes.

Configurable Data Format and Units: It offers the flexibility to configure data output in either 16 – bit integer or 32 – bit real number formats. Additionally, the measurement units can be set to °C, °F, or ohms, making it adaptable to different user preferences and system requirements.

Direct Resistance Measurement: It has the ability to accept direct resistance inputs within a wide range from 0 – 260 ohms to 0 – 4200 ohms. This feature enables it to be used not only for temperature measurement via RTDs but also for applications where direct resistance measurement is needed.

Flexible Wiring: The module is compatible with 2 – wire, 3 – wire, or 4 – wire RTD configurations. This flexibility in wiring allows for easy integration into existing systems and different installation scenarios, providing convenience for engineers during the setup process.

Hot – swap Capability: The hot – swap feature of the IC695ALG508-AA is a significant advantage. It allows for the removal and insertion of the module while the system is powered (RIUP). This means that maintenance or replacement of the module can be carried out without shutting down the entire system, minimizing downtime and ensuring continuous operation in critical industrial processes.

Configurable Data Format and Units: It offers the flexibility to configure data output in either 16 – bit integer or 32 – bit real number formats. Additionally, the measurement units can be set to °C, °F, or ohms, making it adaptable to different user preferences and system requirements.

Application Field

Industrial Process Control: In industrial manufacturing processes such as chemical production, food and beverage processing, and metalworking, precise temperature control is crucial. The IC695ALG508-AA can be used to monitor the temperature of reactors, furnaces, and heat exchangers. For example, in a chemical plant, accurate temperature measurement in a reaction vessel ensures that the chemical reactions occur at the optimal temperature, leading to higher product quality and yield.

HVAC Systems: In heating, ventilation, and air – conditioning systems, maintaining the right temperature is essential for comfort and energy efficiency. The module can be used to monitor the temperature of air handlers, chillers, and boilers. In large commercial buildings, it helps in controlling the temperature in different zones, ensuring a comfortable indoor environment for occupants while optimizing energy consumption.

Power Generation: Power plants, whether they are coal – fired, gas – fired, or nuclear, require precise temperature monitoring for various components. The IC695ALG508-AA can be used to monitor the temperature of turbines, generators, and cooling systems. In a gas – fired power plant, monitoring the temperature of the turbine blades helps in preventing overheating and ensuring the safe and efficient operation of the power generation process.

Environmental Monitoring: In environmental monitoring stations, accurate temperature measurement is important for studying weather patterns, air quality, and climate change. The module can be integrated into sensor networks to collect temperature data from different locations. For example, in a forest area, it can be used to monitor the temperature to detect any abnormal changes that could indicate a potential wildfire risk.

HVAC Systems: In heating, ventilation, and air – conditioning systems, maintaining the right temperature is essential for comfort and energy efficiency. The module can be used to monitor the temperature of air handlers, chillers, and boilers. In large commercial buildings, it helps in controlling the temperature in different zones, ensuring a comfortable indoor environment for occupants while optimizing energy consumption.

Power Generation: Power plants, whether they are coal – fired, gas – fired, or nuclear, require precise temperature monitoring for various components. The IC695ALG508-AA can be used to monitor the temperature of turbines, generators, and cooling systems. In a gas – fired power plant, monitoring the temperature of the turbine blades helps in preventing overheating and ensuring the safe and efficient operation of the power generation process.

Environmental Monitoring: In environmental monitoring stations, accurate temperature measurement is important for studying weather patterns, air quality, and climate change. The module can be integrated into sensor networks to collect temperature data from different locations. For example, in a forest area, it can be used to monitor the temperature to detect any abnormal changes that could indicate a potential wildfire risk.

IC695CRU320-BB

Related Products

IC695ALG506: This is also an analog input module, but it may have differences in the number of channels or supported sensor types compared to the IC695ALG508-AA. It could be a more cost – effective option for applications that require fewer channels or have different sensor compatibility needs.

IC695ACC302: A different type of module within the same product family, perhaps focused on communication or control functions rather than RTD input like the IC695ALG508-AA. It may work in tandem with the IC695ALG508-AA to transfer the temperature data collected by the latter to other parts of the control system.

IC695CHS390: This module might be related to high – speed counting or some other specific function. While it has a different primary function from the IC695ALG508-AA, in a complex industrial automation setup, both modules could be used together to meet the diverse requirements of the system, such as counting events related to temperature – controlled processes.

IC695MDL655: Another module that could be part of the PACSystems RX3i family. It may have its own set of features, like digital input/output capabilities, which can complement the analog RTD input functionality of the IC695ALG508-AA in an overall industrial control system.

IC695CMM008: A communication – related module that may be used to ensure seamless data transfer between the IC695ALG508-AA and other components in a networked industrial environment. It can enhance the connectivity of the IC695ALG508-AA to other modules or control stations.

IC695ACC302: A different type of module within the same product family, perhaps focused on communication or control functions rather than RTD input like the IC695ALG508-AA. It may work in tandem with the IC695ALG508-AA to transfer the temperature data collected by the latter to other parts of the control system.

IC695CHS390: This module might be related to high – speed counting or some other specific function. While it has a different primary function from the IC695ALG508-AA, in a complex industrial automation setup, both modules could be used together to meet the diverse requirements of the system, such as counting events related to temperature – controlled processes.

IC695MDL655: Another module that could be part of the PACSystems RX3i family. It may have its own set of features, like digital input/output capabilities, which can complement the analog RTD input functionality of the IC695ALG508-AA in an overall industrial control system.

IC695CMM008: A communication – related module that may be used to ensure seamless data transfer between the IC695ALG508-AA and other components in a networked industrial environment. It can enhance the connectivity of the IC695ALG508-AA to other modules or control stations.

Installation and Maintenance

Pre – installation preparation: Before installing the IC695ALG508-AA, carefully read the installation manual provided by Emerson (formerly GE Intelligent Platforms). Ensure that the installation environment meets the specified temperature (0 – 60 °C for operation, – 40 – 85 °C for storage), humidity (5 – 95 %, non – condensing), and other environmental requirements. Check the compatibility of the module with the existing PACSystems RX3i setup, including the backplane and other connected components. Mount the module securely in the appropriate slot on the backplane, following the correct orientation. Connect the RTD sensors to the module using the appropriate wiring configuration (2 – wire, 3 – wire, or 4 – wire) as per the sensor requirements.

Maintenance recommendations: Regularly inspect the IC695ALG508-AA for any signs of physical damage, such as cracks or loose connections. Monitor the module’s fault status indicators, which include watchdog, RAM fail, and flash fail statuses. If any faults are detected, refer to the troubleshooting guide in the manual. Periodically check the accuracy of the temperature measurements by comparing the readings with calibrated reference sensors. Clean the module and its connection points to remove dust and debris that could affect its performance. If the module needs to be replaced, take advantage of its hot – swap capability to minimize system downtime.

Maintenance recommendations: Regularly inspect the IC695ALG508-AA for any signs of physical damage, such as cracks or loose connections. Monitor the module’s fault status indicators, which include watchdog, RAM fail, and flash fail statuses. If any faults are detected, refer to the troubleshooting guide in the manual. Periodically check the accuracy of the temperature measurements by comparing the readings with calibrated reference sensors. Clean the module and its connection points to remove dust and debris that could affect its performance. If the module needs to be replaced, take advantage of its hot – swap capability to minimize system downtime.

Product Guarantee

Emerson stands firmly behind the quality of the IC695ALG508-AA module. The product typically comes with a 12 – month warranty, during which any defects in materials or workmanship will be addressed. Their global technical support network is available to assist customers with installation guidance, operation advice, and troubleshooting. Whether it’s answering questions about sensor compatibility or helping to resolve issues related to data output, Emerson’s technical experts are ready to provide solutions. This strong product guarantee gives customers the confidence that the IC695ALG508-AA will perform reliably in their industrial applications, contributing to the long – term stability and efficiency of their automation systems.