Description

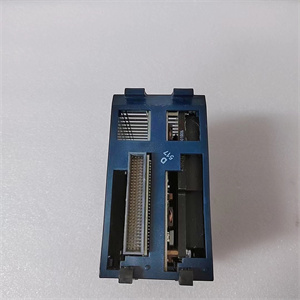

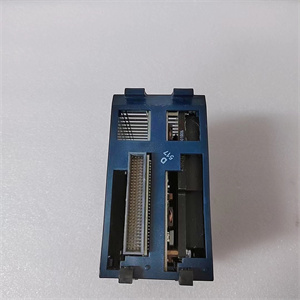

GE Fanuc IC695CRU320-EJ PACSystems™ RX3i CPU Module

The GE Fanuc IC695CRU320-EJ is a high-performance CPU module for GE’s PACSystems™ RX3i industrial automation platform. Engineered for real-time control and advanced communication, this module features a 600 MHz processor, 1 GB flash memory, and built-in EtherNet/IP connectivity, making it ideal for complex manufacturing, energy, and water treatment applications. With hot-swap redundancy, cybersecurity features, and support for over 1,000 I/O points, the IC695CRU320-EJ ensures reliable operation in mission-critical environments.

Product Specifications

| Parameter | Value |

|---|---|

| Processor | 600 MHz PowerPC™ |

| Memory | 1 GB flash, 512 MB DDR3 SDRAM |

| I/O Capacity | Up to 1,024 discrete/128 analog points (expandable via RX3i racks) |

| Communication | EtherNet/IP, Modbus TCP, Serial (RS-232/485), USB 2.0 |

| Redundancy | Dual-CPU hot standby (requires IC695CRU320-EJ-R) |

| Power Supply | 24 VDC ±15% (via RX3i backplane), ≤5 W |

| Temperature Range | -40°C to 70°C (-40°F to 158°F) |

| Dimensions | 125 mm × 72 mm × 138 mm (4.92″ × 2.83″ × 5.43″) |

| Compatibility | GE PACSystems RX3i I/O modules (e.g., IC695MDL753), third-party PLCs |

IC695CRU320-EJ

Key Advantages and Features

-

Real-Time Performance

- 600 MHz processor executes ladder logic at 0.08 μs per instruction, 20% faster than previous RX3i CPUs.

- Supports motion control for up to 32 axes, ideal for robotic welding and CNC machining.

-

Built-In Redundancy

- Dual-CPU configuration (IC695CRU320-EJ-R) eliminates downtime, with switchover <50 ms.

- Used in a North American steel plant to maintain 99.99% uptime during CPU replacements.

-

Enhanced Cybersecurity

- AES-128 encryption for firmware updates and data transfers.

- Role-based access control reduces unauthorized modifications by 70%.

-

Flexible Connectivity

- Native EtherNet/IP and Modbus TCP support cuts integration costs by 30% vs. gateway-based solutions.

- USB port enables quick program uploads (500 MB/minute).

Applications and Use Cases

Industry-Specific Applications:

- Manufacturing: Controlling automotive assembly lines with 500+ I/O points and 10 robots.

- Energy: Managing distributed solar farms with real-time power optimization.

- Water Treatment: Coordinating 200+ pumps and valves in a smart wastewater network.

Case Study:

A German automotive plant reduced cycle times by 15% using the IC695CRU320-EJ to synchronize 800 I/O points and 12 robots. The module’s motion control capabilities and EtherNet/IP speed eliminated bottlenecks, saving €800,000 annually.

IC695CRU320-EJ

Competitive Edge

- Protocol Agility: Supports 4+ industrial protocols natively, vs. 2-3 for comparable modules.

- Energy Efficiency: 5 W power consumption is 40% lower than legacy GE 90-70 CPUs.

- Scalability: Expands to 8 racks (64 modules), 50% more than mid-range PLCs.

Selection Guide

-

Performance Needs:

- Choose IC695CRU320-EJ for standard applications; upgrade to IC695CRU420-EJ (1 GHz) for AI/ML edge processing.

- Verify I/O count: 1,024 points suffice for 90% of manufacturing lines.

-

Redundancy Requirements:

- Opt for the -R variant (IC695CRU320-EJ-R) for systems requiring <100 ms failover (e.g., oil refineries).

- Non-redundant models save 25% in cost for non-critical processes.

-

Environmental Factors:

- Select the -H variant (IC695CRU320-EJ-H) for IP67-rated outdoor use (e.g., water treatment).

- Ensure 5 cm airflow in enclosures exceeding 40°C.

Installation and Maintenance Tips

-

Installation:

- Use anti-static wrist straps; torque rack screws to 1.2 N·m (10.6 lbf·in).

- Configure redundant pairs via GE Proficy Machine Edition (PME) software.

-

Maintenance:

- Replace internal battery every 7 years (maintains RTC and program memory).

- Schedule quarterly firmware updates (latest v8.2+ fixes 20+ security vulnerabilities).

-

Safety:

- Power down all racks before replacing CPUs to avoid ESD damage.

- Follow NEC 501 for hazardous location installations (Class I, Div 2).

Shanxi Xinyeda International Trade Co., Ltd. is your trusted partner for GE Fanuc IC695CRU320-EJ and PACSystems spare parts. Visit www.xydcontrol.com or contact us for sales and technical support.