Description

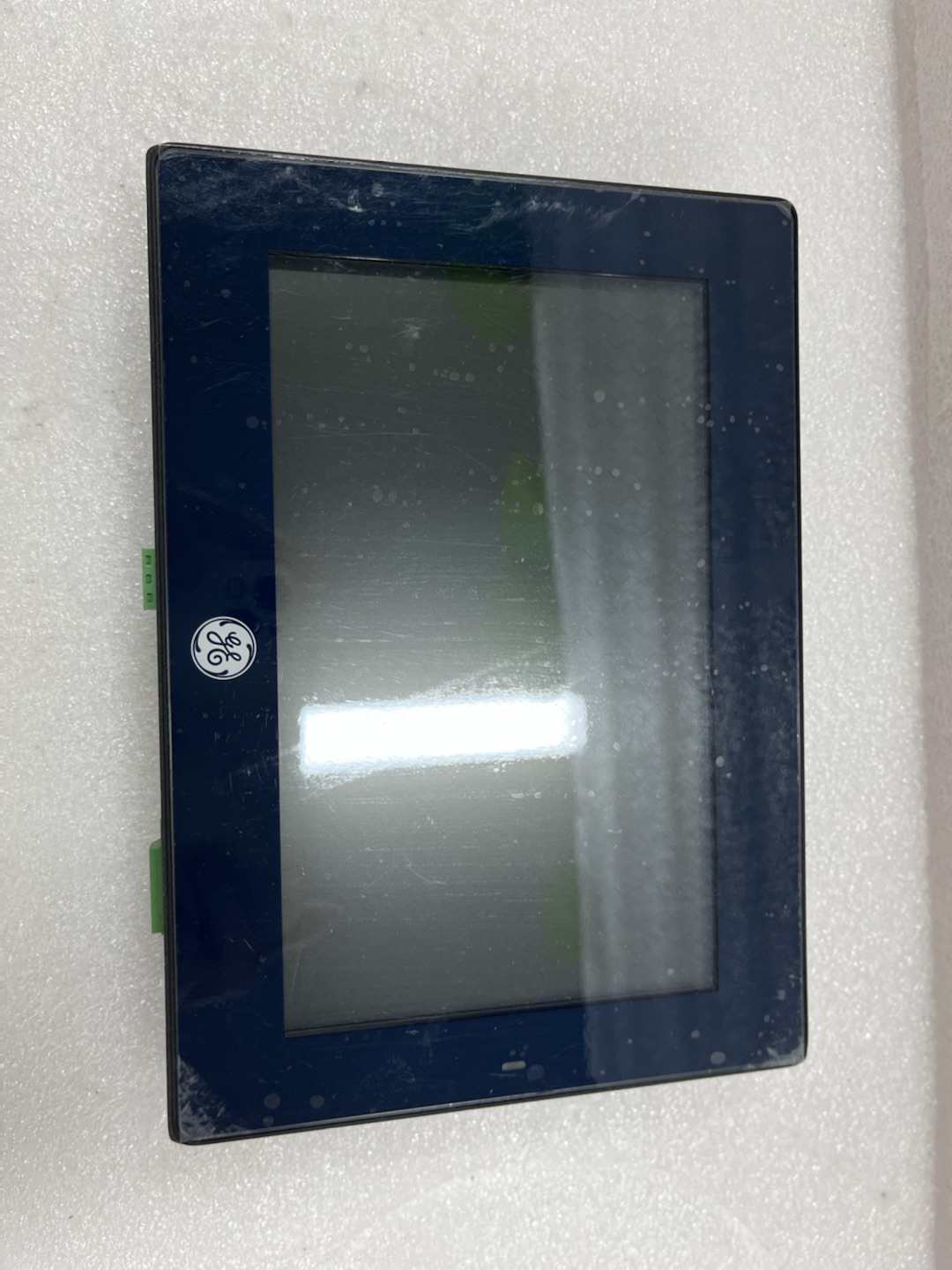

GE Fanuc IC755CSW07CDA

The IC755CSW07CDA is a 7-inch industrial human-machine interface (HMI) designed by GE Fanuc (now part of Emerson Automation Solutions) for real-time monitoring and control in harsh environments. As part of the QuickPanel+ series, it combines advanced touchscreen technology with robust connectivity, making it suitable for applications in manufacturing, energy, and transportation. Below is a detailed technical overview based on available documentation and industry references:

The IC755CSW07CDA is a 7-inch industrial human-machine interface (HMI) designed by GE Fanuc (now part of Emerson Automation Solutions) for real-time monitoring and control in harsh environments. As part of the QuickPanel+ series, it combines advanced touchscreen technology with robust connectivity, making it suitable for applications in manufacturing, energy, and transportation. Below is a detailed technical overview based on available documentation and industry references:

1. Product Description

TheIC755CSW07CDA is engineered to provide intuitive operator interaction and process visualization in industrial settings. Key features include:

- 7-inch Widescreen Display: High-resolution TFT LCD (800 x 480 pixels) with projected capacitive multi-touch support for gloved operation.

- Powerful Processor: Intel Freescale i.MX 535 1 GHz ARM Cortex-A8 processor with 512 MB DDR2 SDRAM and 256 MB NAND flash for smooth graphics and data processing.

- Industrial-Grade Design: IP65-rated enclosure with conformal coating to resist dust, moisture, and vibration.

- Multi-Protocol Connectivity: Supports Ethernet, RS-232, USB 2.0, and SD card expansion for flexible integration with PLCs, drives, and enterprise systems.

2. Technical Specifications

| Parameter | Specification |

|---|---|

| Manufacturer | General Electric (GE) / Emerson Automation Solutions |

| Series | QuickPanel+ |

| Type | Operator Interface Terminal (OIT) / HMI |

| Display | 7-inch TFT widescreen, 800 x 480 pixels, 65k colors |

| Processor | Intel Freescale i.MX 535 1 GHz ARM Cortex-A8 |

| Memory | 512 MB DDR2 SDRAM, 256 MB NAND flash, 512 KB SRAM |

| Communication | 1x Ethernet (10/100 Mbps), 1x RS-232, 2x USB 2.0 (Type-A), 1x USB 2.0 (Mini-B) |

| Power Supply | 12–24 VDC (±20% tolerance), 15 W max power consumption |

| Environmental Ratings | -25°C to 65°C operating temperature; 0–55°C with full touch functionality |

| Certifications | CE, UL, RoHS, EN 61000-6-2/3 (EMC compliance) |

IC755CSW07CDA

3. Functionality and Integration

The IC755CSW07CDA serves as a central hub for industrial automation systems, enabling:

- HMI Operations: Real-time monitoring of process variables, alarm management, and recipe control through a user-friendly interface.

- Programming Flexibility: Supports IEC 61131-3 programming languages (Ladder Logic, Function Block Diagram) via Proficy Machine Edition software.

- Data Handling: Built-in data historian for trend analysis and HTML5 browser for remote access to reports and training materials.

- Safety Compliance: Integrates with safety PLCs (e.g., GE’s IC697 series) to implement emergency stop protocols and overload protection.

4. Application Scenarios

- Manufacturing: Used in assembly lines and packaging equipment for operator guidance and machine status monitoring.

- Energy: Deployed in power plants and refineries to control turbines, boilers, and process valves.

- Transportation: Installed in AGVs and rail systems for route planning and diagnostics.

- HVAC/Building Automation: Manages HVAC systems and lighting controls in smart buildings.

Case Study:

In a petrochemical plant, the IC755CSW07CDA was used to monitor distillation columns, reducing operator errors by 30% through real-time visualization of temperature and pressure data.

In a petrochemical plant, the IC755CSW07CDA was used to monitor distillation columns, reducing operator errors by 30% through real-time visualization of temperature and pressure data.

5. Competitor Comparison

| Feature | IC755CSW07CDA | ABB Panel PC 600 | Siemens SIMATIC IPC427D |

|---|---|---|---|

| Touchscreen Technology | Projected capacitive (multi-touch) | Resistive (single-touch) | Projected capacitive (multi-touch) |

| Native PLC Compatibility | GE 90-70, PACSystems | ABB AC500 | Siemens S7-1200/1500 |

| Environmental Resilience | IP65 | IP65 | IP65 |

| Software Ecosystem | Proficy Machine Edition | ABB Automation Builder | TIA Portal |

| Price Range | Mid-tier ($2,000–$3,500) | High-tier ($3,000–$5,000) | Mid-tier ($2,500–$4,000) |

IC755CSW07CDA

6. Selection Guidelines

- Display Requirements: Opt for the 7-inch model (IC755CSW07CDA) for compact spaces; larger 10-inch variants (e.g., IC755SUE10CTD) are available for complex applications.

- Redundancy: Pair with GE’s PACSystems RX3i for dual-controller configurations in mission-critical processes.

- Environment: Choose the conformal-coated variant (suffix “K”) for corrosive or high-dust environments.

- Budget: Refurbished units (e.g., from Shanxi Xinyeda International Trade Co., Ltd.) offer cost savings without compromising performance.

7. Precautions

- ESD Protection: Handle with anti-static gloves and storage bags to prevent damage to sensitive components.

- Firmware Updates: Regularly update firmware via GE’s Proficy Machine Edition to address security vulnerabilities.

- Mounting: Use VESA 75 brackets for wall or panel installation to ensure stability in high-vibration environments.

- Power Supply: Use filtered power sources to avoid voltage spikes, especially in regions with unstable grids.