Description

Product Overview

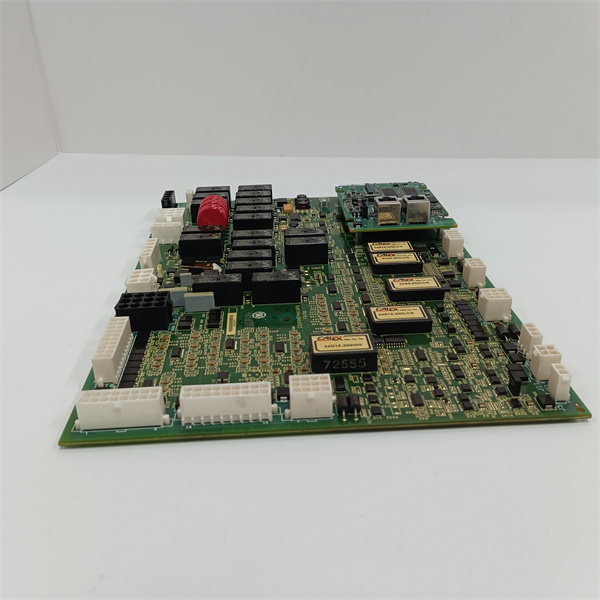

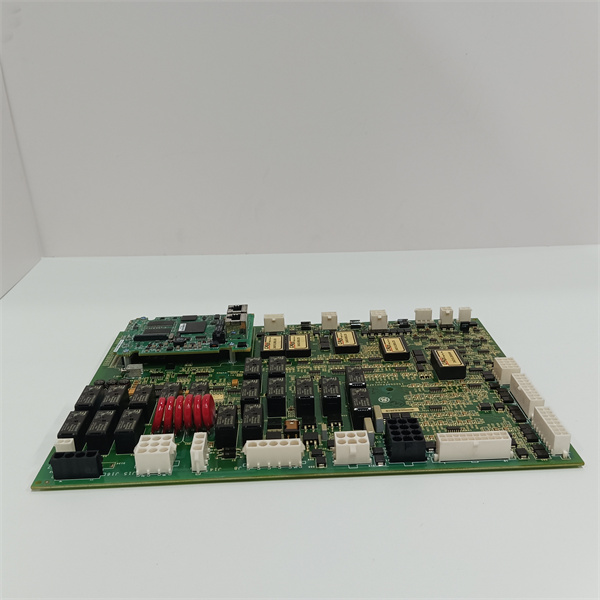

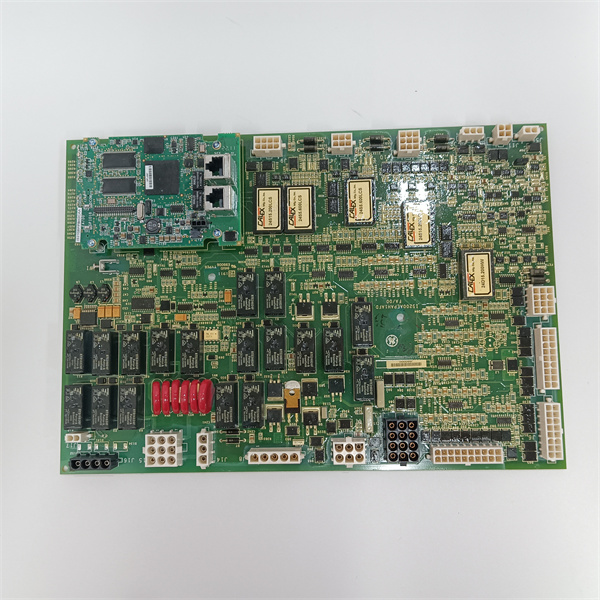

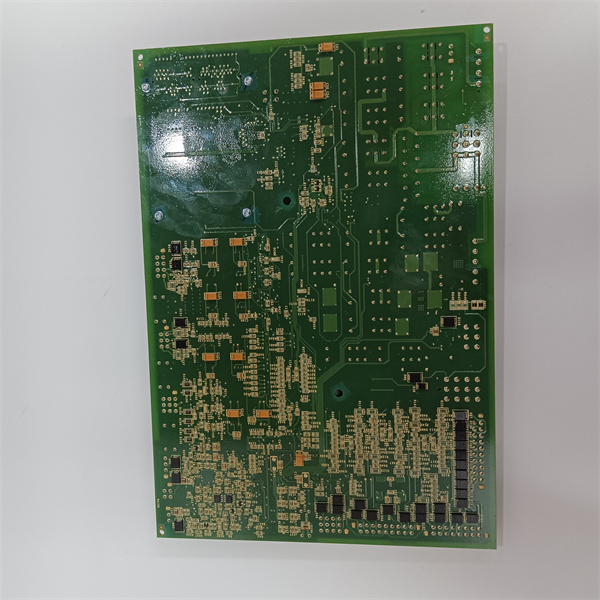

The GE IS200AEPAH1AFD is a printed circuit board crafted by General Electric (GE) for its esteemed Mark VI turbine control system. As a key part of the Mark VI series, which is renowned for its application in controlling and managing GE – geared gas, wind, and steam turbine automated drive assemblies, the IS200AEPAH1AFD holds significant importance.

This board, with its AEPA (Exciter Power Amplifier Board) functionality, is designed to distribute and manage power within the system. It plays a critical role in ensuring stable power supply to other modules, which is essential for the seamless operation of the entire turbine control setup. Whether it’s in a power generation plant where gas or steam turbines are in use or in a wind energy farm with wind turbines, the GE IS200AEPAH1AFD contributes to the reliable and efficient control of these vital energy – producing assets.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | IS200AEPAH1AFD |

| Manufacturer | GE |

| Product Type | Printed Circuit Board |

| Ambient Temperature Range | – 40 to + 70 °C |

| Functional Acronym | AEPA |

| Model Type | Printed Circuit Board |

| Original Manufacturer | General Electric Company USA, GE Industrial Systems |

| Series Manual | GER – 4193 A GE Power Systems Manual |

| Weight | Approximately 3 lbs |

| Connector Type | 2 sub – D pin connectors, 2 three – plug connectors, male pin connectors for auxiliary board (in top left corner) |

| Redundancy Support | Compatible with simplex, dual, and triple redundancy |

| Communication Protocols | Ionet or Unit Data Highway (UDH) |

| Component Configuration | Equipped with six metal oxide varistors (MOVs) |

IS200AEPAH1AFD

Main Features and Advantages

Redundancy and Flexibility

The GE IS200AEPAH1AFD offers support for simplex, dual, and triple redundancy configurations. This adaptability allows it to be used in various operational scenarios, from less – critical systems with simplex redundancy to highly reliable setups requiring triple modular redundancy (TMR). This flexibility ensures that the board can meet the specific reliability needs of different industrial applications.

Communication Capabilities

With support for both Ionet and Unit Data Highway (UDH) communication protocols, the board enables seamless communication within the Mark VI system. Additionally, it can communicate with other GE components such as Fanuc PLCs and EX2000 generator excitation controls. This extensive communication compatibility makes it easier to integrate into complex industrial networks, enhancing overall system connectivity and control.

Auxiliary Board Connectivity

Designed to connect with an optional auxiliary board through male pin connectors located in the top left corner, the IS200AEPAH1AFD can enhance its functionality. The ability to expand with an auxiliary board allows for customization based on specific application requirements, providing additional processing power or interface options as needed.

Component Configuration

Equipped with components like two three – plug connectors and six metal oxide varistors (MOVs), the board is built for reliable performance. The MOVs, which are lined up in the upper right – hand corner, help protect the board from voltage surges, ensuring its durability and long – term stable operation, even in environments with electrical fluctuations.

Application Field

Power Generation

In power plants using gas or steam turbines, the GE IS200AEPAH1AFD is crucial for controlling the turbine operations. It manages power distribution to various components involved in the power generation process, ensuring stable and efficient electricity production. For example, it can supply power to control modules that regulate the fuel supply to the gas turbine, optimizing combustion and power output.

Wind Energy

In wind farms, the board is used in the control systems of wind turbines. It helps in managing the power amplification and distribution for the various electrical components within the turbine, such as the generator control system. By ensuring stable power supply and control, it contributes to the reliable operation of wind turbines, maximizing energy capture and conversion.

Industrial Automation

In industrial settings where turbines are used for mechanical drive applications, the IS200AEPAH1AFD plays a key role. It can be part of a system that controls the speed and operation of turbines driving large – scale industrial machinery, like compressors in a chemical plant. The board’s ability to manage power and communicate with other components enables precise control of the industrial process.

IS200AEPAH1AFD

Related Products

IS200AEPAH1AHD: Another printed circuit board in the same family, likely with similar functionality but may have different revisions or specific application – targeted features compared to the IS200AEPAH1AFD.

GE IS200ACLEH1BCB: A PCB for the GE Mark VI Speedtronic series. While the IS200AEPAH1AFD focuses on power amplification and distribution, the ACLEH1BCB may handle other aspects of the control system, such as signal conditioning or communication within the system.

GE IS200AEPCH1A: A 电路板组件 that might be used in a related control system, perhaps with different input/output capabilities or control logic, but still part of the GE’s suite of products for industrial control.

GE IS200STCIH6ADD: This component is related to the Mark VI Speedtronic turbine control system. It could be involved in different functions like providing protection and monitoring in mechanical drive applications, complementing the power – related functions of the IS200AEPAH1AFD.

GE IS200EHPAG1AFD: A semi – height module, which might have different form factor and functionality. It could be used in different parts of the control system, such as for specific input/output tasks or as a more compact solution in space – constrained environments compared to the IS200AEPAH1AFD.

GE IS200ACLEH1BCB: A PCB for the GE Mark VI Speedtronic series. While the IS200AEPAH1AFD focuses on power amplification and distribution, the ACLEH1BCB may handle other aspects of the control system, such as signal conditioning or communication within the system.

GE IS200AEPCH1A: A 电路板组件 that might be used in a related control system, perhaps with different input/output capabilities or control logic, but still part of the GE’s suite of products for industrial control.

GE IS200STCIH6ADD: This component is related to the Mark VI Speedtronic turbine control system. It could be involved in different functions like providing protection and monitoring in mechanical drive applications, complementing the power – related functions of the IS200AEPAH1AFD.

GE IS200EHPAG1AFD: A semi – height module, which might have different form factor and functionality. It could be used in different parts of the control system, such as for specific input/output tasks or as a more compact solution in space – constrained environments compared to the IS200AEPAH1AFD.

Installation and Maintenance

Pre – installation preparation: Before installing the GE IS200AEPAH1AFD, ensure that the power to the Mark VI turbine control system is turned off. Check the VME rack where it will be installed to confirm there is an available slot. Inspect the board for any visible physical damage, such as cracks or bent connectors. Clean the connection ports and the VME slot to remove any dust or debris that could affect the connection.

Maintenance recommendations: Regularly monitor the IS200AEPAH1AFD for any signs of overheating, which could be indicated by unusual discoloration of the board or components. Check the MOVs periodically to ensure they are functioning properly and have not been damaged by voltage surges. If there are any communication issues within the system related to the board, refer to the product manual for troubleshooting steps. In case of hardware failures, contact GE’s technical support for repair or replacement options.

Product Guarantee

GE stands firmly behind the quality of the GE IS200AEPAH1AFD. The company conducts rigorous testing during the manufacturing process to ensure the board meets high – industry standards. In terms of after – sales service, GE offers comprehensive technical support. If the product experiences any quality – related issues within the warranty period, GE will provide repair or replacement services free of charge. This commitment reflects GE’s confidence in the product, giving customers peace of mind when using the IS200AEPAH1AFD in their industrial applications.