Description

Product Overview

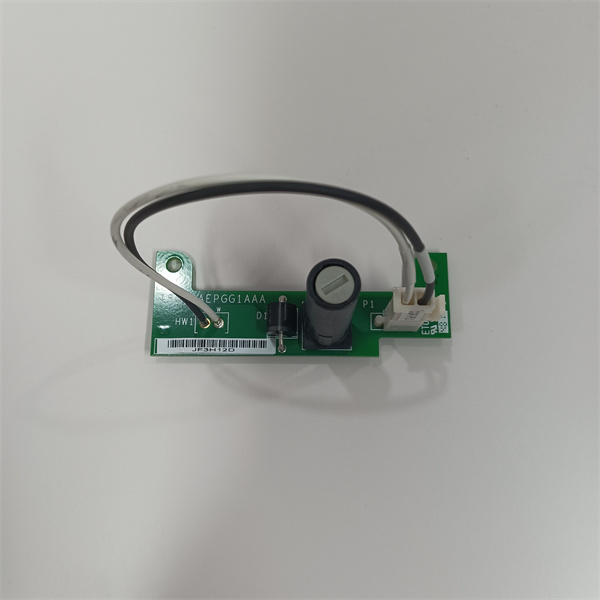

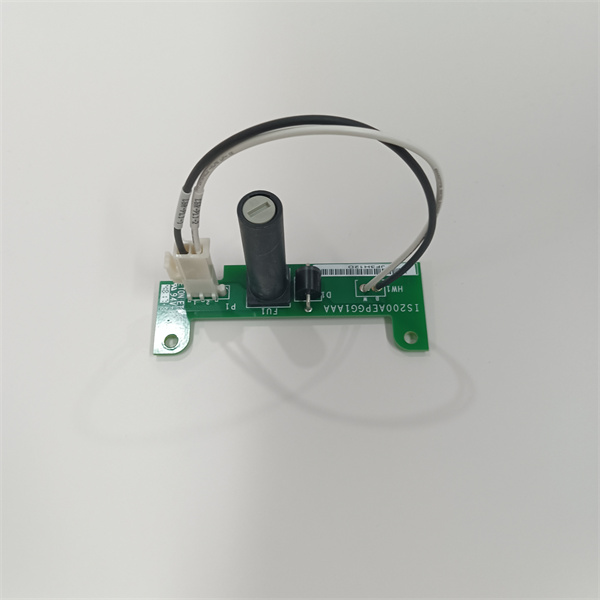

The GE IS200AEPGG1AAA is a specialized Printed Circuit Board (PCB) module meticulously crafted by General Electric. It holds a significant place within the GE Speedtronic Mark VIe Wind turbine control system. This system is designed to ensure the efficient and reliable operation of wind turbines, and the GE IS200AEPGG1AAA plays a crucial role in this setup.

Functionally, the GE IS200AEPGG1AAA serves as an important part of the control infrastructure. It is involved in tasks related to signal processing and communication within the wind turbine control environment. By accurately handling various input and output signals, it enables seamless coordination between different components of the wind turbine system. This ensures that the wind turbine operates at optimal levels, maximizing energy production while maintaining safety and reliability. Its integration within the Mark VIe Wind series underlines its importance in modern wind energy applications, where precision and performance are of utmost importance.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | IS200AEPGG1AAA |

| Manufacturer | GE |

| Product Type | Printed Circuit Board Module |

| Series | Mark VIe Wind |

| Functional Acronym | AEPG |

| Functional Description | AEPG Module PCB |

| PCB Coating | Normal Coating |

| Functional Revision | A |

| Dimensions | Approximately 4 inches lengthwise by 1 inch wide (board itself), requires about 6 inches thickness clearance considering attached wires |

| Mounting Holes | Factory – drilled holes for installation, insulated for safety |

| Connector Cables | Dual selection of wires (labeled “B” and “W” or 1 and 2 at different ports) creating a circuit loop from plug labeled P1 to port labeled HW1 |

| Fuse | Singular fuse (labeled FU1) with a diode for voltage protection |

IS200AEPGG1AAA

Main Features and Advantages

Precise Signal Handling

The GE IS200AEPGG1AAA is engineered to precisely handle input and output signals within the wind turbine control system. This precision is vital as it allows for accurate monitoring and control of the wind turbine’s operations. For example, it can accurately process signals from sensors that detect wind speed, blade position, and generator status. Based on these processed signals, it can send appropriate control commands to ensure the turbine functions optimally, whether it’s adjusting the blade pitch to capture more wind energy or controlling the generator’s speed.

Durable and Reliable Design

With a normal PCB coating and insulated mounting holes, the module is built to withstand the rigors of industrial environments. The durable construction ensures that it can operate reliably even in harsh conditions, such as high humidity, temperature variations, and electrical interference common in wind turbine installations. The use of high – quality components, like the singular fuse with a diode for voltage protection, further enhances its reliability, protecting the module from electrical surges and ensuring long – term stable operation.

Integration within a Robust System

As part of the well – known GE Speedtronic Mark VIe Wind series, the GE IS200AEPGG1AAA benefits from the overall robustness of the system. It can seamlessly integrate with other components in the wind turbine control setup. This integration allows for efficient data sharing and coordinated operation among different parts of the system, such as other control modules, sensors, and actuators. This cohesive operation contributes to the overall high – performance and reliability of the entire wind turbine control system.

Application Field

The GE IS200AEPGG1AAA finds its primary application in wind turbine control systems. In onshore wind farms, it plays a key role in ensuring the smooth operation of individual wind turbines. By processing signals related to wind conditions and turbine performance, it helps in maximizing energy production. For instance, it can analyze wind speed and direction data to adjust the orientation of the turbine nacelle for optimal wind capture.

In offshore wind farms, where the operating environment is even more challenging due to factors like salt – laden air and rough weather, the durability and reliability of the GE IS200AEPGG1AAA become even more crucial. It continues to function effectively, maintaining the control and monitoring of the wind turbines. This ensures that the offshore wind farm can operate efficiently and provide a stable power supply to the grid, despite the harsh offshore conditions. Overall, in the wind energy industry, the GE IS200AEPGG1AAA is an essential component for maintaining the efficiency, reliability, and safety of wind turbine operations.

IS200AEPGG1AAA

Related Products

- GE IS200AEPGG1A: This is likely a base version or an earlier iteration of the GE IS200AEPGG1AAA. The “AAA” version might have some improvements or differences in configuration compared to the “A” version. For example, it could have enhanced signal processing capabilities or a different PCB coating for better protection in specific environments.

- GE IS200AEPCH1A: It is a different PCB module in the GE product line. While the GE IS200AEPGG1AAA is focused on its role within the Mark VIe Wind turbine control system, the GE IS200AEPCH1A might have a different set of functions, perhaps more related to general control or signal processing in other GE – based industrial control systems. It could also have different physical dimensions or connection interfaces.

- GE Mark VIe Wind Turbine Control System Components: There are various other components within the Mark VIe Wind turbine control system, such as sensors and actuators, that work in tandem with the GE IS200AEPGG1AAA. Sensors provide the input signals that the module processes, and actuators receive the control commands generated by the module. For example, wind speed sensors send data to the GE IS200AEPGG1AAA, which then calculates and sends commands to the pitch actuators to adjust the turbine blades.

- GE Speedtronic MKVI Gas Turbine Control Modules: Although designed for gas turbine control, these modules share some similarities with the components in the wind turbine control system. They may use similar signal processing techniques and communication protocols. The GE IS200AEPGG1AAA can offer insights or serve as a reference for the design and operation of these gas turbine control modules, and vice versa, in terms of general control system architecture and component functionality.

- GE MMII – PD – 1 – 2 – 120: This is a motor protection and control device. In a wind turbine, motors are used for various functions like blade pitch adjustment and yaw control. The GE MMII – PD – 1 – 2 – 120 can protect and control these motors, and the GE IS200AEPGG1AAA can interact with it. For example, the GE IS200AEPGG1AAA can send control signals to the GE MMII – PD – 1 – 2 – 120 based on the overall turbine operating conditions, ensuring coordinated operation.

Installation and Maintenance

Pre – installation preparation: Before installing the GE IS200AEPGG1AAA, ensure that the power to the wind turbine control system is switched off to avoid any electrical hazards. Carefully inspect the module for any visible signs of damage during transit, such as cracks on the PCB or loose components. Verify that the installation location meets the environmental requirements in terms of temperature and humidity. Familiarize yourself with the wiring diagram provided in the product manual. Make sure that the connectors on the GE IS200AEPGG1AAA match the corresponding connectors in the control system. Also, check the integrity of the mounting holes and ensure that the necessary mounting hardware is available.

Maintenance recommendations: Regularly monitor the GE IS200AEPGG1AAA for any abnormal behavior. Check for any overheating issues by feeling the temperature of the module (but ensure the power is off when doing so). Look for any signs of corrosion, especially in harsh environments like offshore wind farms. Periodically clean the module gently to remove dust and debris that could affect its performance. Inspect the connection cables for any signs of wear or looseness. If any issues are detected, refer to the troubleshooting section of the product manual. For more complex problems, contact GE’s technical support team, who can provide specialized guidance and assistance to keep the GE IS200AEPGG1AAA in optimal working condition.

Product Guarantee

GE stands firmly behind the quality of the GE IS200AEPGG1AAA. The product comes with a comprehensive quality assurance program. During the specified warranty period, if the module is found to have defects in materials or workmanship, GE will provide free repair or replacement services. Their dedicated technical support team is available around the clock to assist customers. Whether it’s answering installation – related queries, providing troubleshooting advice, or helping with performance optimization, GE’s support ensures that customers can rely on the GE IS200AEPGG1AAA for their wind turbine control needs. This commitment to quality and customer satisfaction reflects GE’s confidence in the reliability and performance of the GE IS200AEPGG1AAA in the demanding wind energy industry.