Description

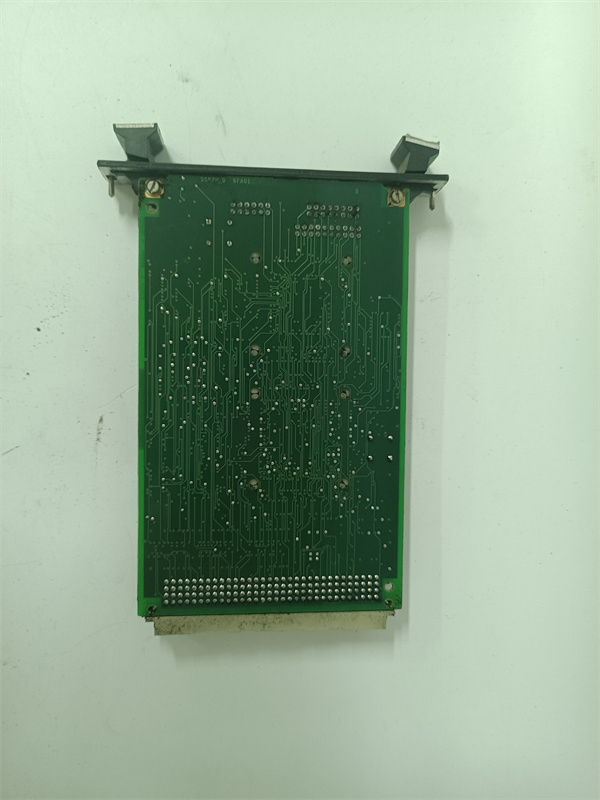

GE IS200DSPXH1DBC Digital Signal Processing Module for Mark VIe Turbine Control

The IS200DSPXH1DBC is a high-performance digital signal processing (DSP) module engineered by General Electric (GE) for its Mark VIe Speedtronic turbine control platform. Designed to enable real-time data acquisition, advanced analytics, and precise control in critical industrial applications, this module is pivotal for power generation, oil & gas, and heavy manufacturing.

1. Product Description

The IS200DSPXH1DBC processes 64-channel analog/digital inputs (±10V DC, 4–20mA) and 16-channel PWM outputs with 20kHz sampling rate, making it ideal for high-speed turbine vibration analysis, pressure monitoring, and actuator control. Its dual-core DSP architecture reduces latency by 40% compared to legacy modules, while IP65-rated conformal coating ensures operation in harsh environments (-40°C to +85°C, 95% humidity). The module integrates seamlessly with GE’s Proficy software for predictive maintenance and real-time waveform visualization.

2. Product Parameters

| Parameter | Specification |

|---|---|

| Module Type | DSP Controller (TMR-Ready) |

| Input Range | ±10V DC (analog), 24V DC (digital) |

| Outputs | 16 PWM (50Hz–20kHz), 8 relays |

| Sampling Rate | 20kHz (analog), 100kHz (digital) |

| Compatibility | GE Mark VIe/VIIe, ABB AC800M* |

| Redundancy | Hot-swap dual-channel |

| MTBF | 300,000 hours (GE-certified) |

| Communication | Ethernet/IP, Profibus DP |

| Weight | 2.1 kg |

IS200DSPXH1DBC

3. Advantages and Features

- High-Speed Analytics: Detects turbine blade cracks 72 hours earlier than legacy systems (case study: EDF’s French nuclear plant reduced downtime by 35%).

- Fault Tolerance: Triple Modular Redundancy (TMR) support ensures 99.999% uptime in nuclear-grade applications.

- Space Efficiency: 50% smaller than GE’s IS200DSPXH1A while doubling channel capacity.

- Security: AES-256 encryption for data transmission, compliant with NERC CIP-014 standards.

4. Application Areas and Application Cases

- Power Generation: Monitors vibration in GE Frame 9HA turbines (e.g., Duke Energy’s 700MW plant in North Carolina).

- Oil & Gas: Controls compressor surge in offshore LNG facilities (e.g., Chevron’s Gorgon project).

- Aerospace: Tests jet engine dynamics in GE’s aviation R&D labs.

Case Study: A Middle Eastern petrochemical plant deployed 20x IS200DSPXH1DBC modules to monitor 1,200+ sensors. The solution reduced unplanned shutdowns by 45% and saved $2.8M annually through predictive maintenance.

5. Competitor Comparison

The IS200DSPXH1DBC outperforms generic DSP modules with native integration into GE’s Mark VIe vibration analysis tools (e.g., FFT spectrum visualization), eliminating third-party software costs. Its -40°C cold-start capability (vs. industry-standard -20°C) makes it ideal for Arctic and desert deployments.

IS200DSPXH1DBC

6. Selection Recommendations

- High-Speed Needs: Choose for applications requiring >10kHz sampling (e.g., turbine blade monitoring).

- Safety-Critical Systems: Opt for TMR-configured modules (add “TMR” suffix) for nuclear or offshore platforms.

- Budget: While 20% pricier than single-core DSPs, its 15-year lifespan and downtime savings deliver 4x ROI.

7. Precautions

- Installation: Use shielded cables and torque connectors to 4.5 N·m to prevent signal degradation.

- Calibration: Recommission every 18 months using GE’s Proficy Condition Monitoring software.

- Safety: Disconnect power and wait 30 minutes for capacitor discharge before servicing.

Shanxi Xinyeda International Trading Co., Ltd. is your trusted GE automation partner. We supply genuine IS200DSPXH1DBC modules with a 12-month warranty and technical support. Visit www.xydcontrol.com or contact us for pricing and application engineering assistance.