Description

Product Overview

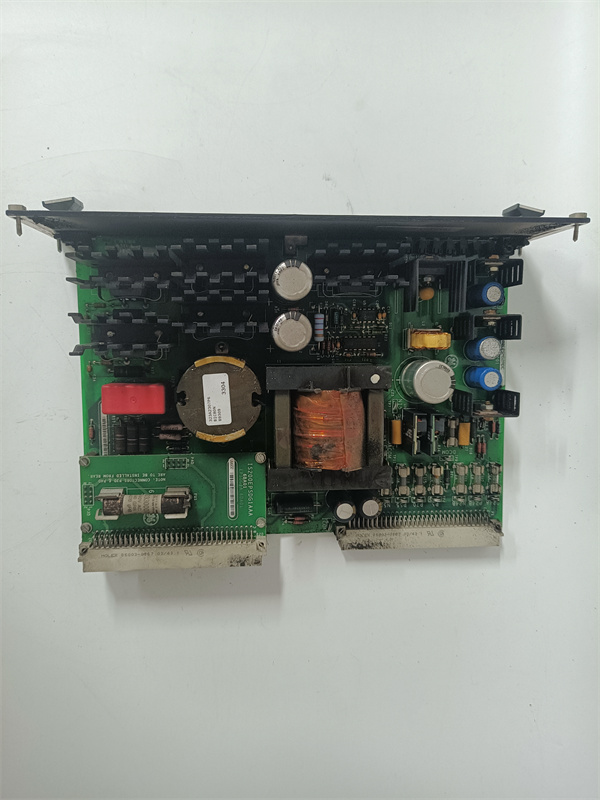

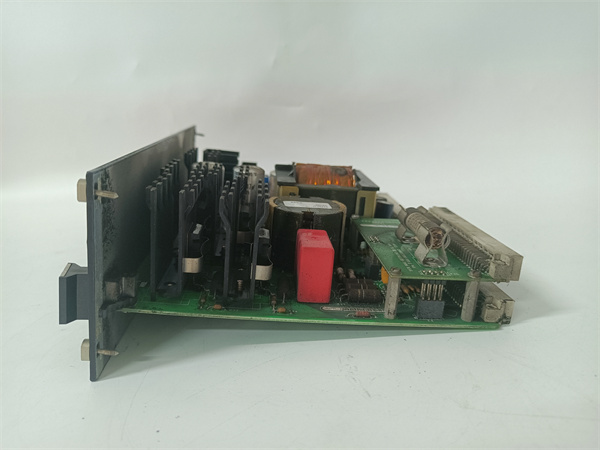

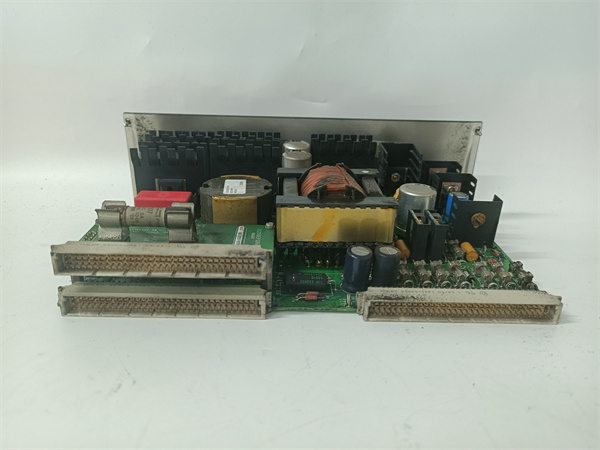

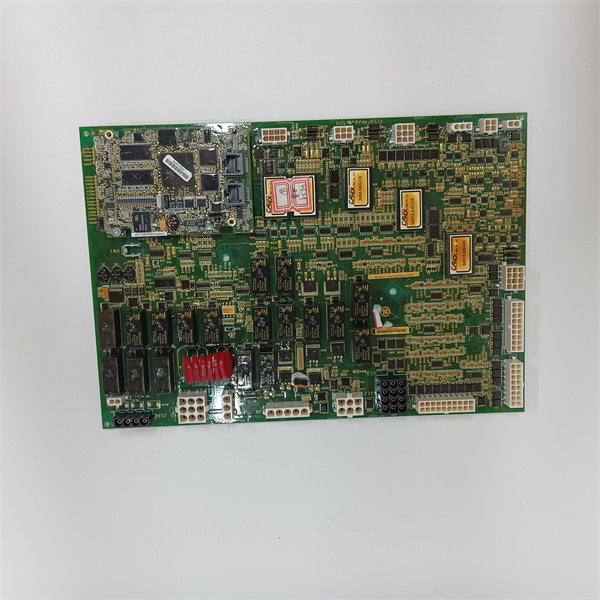

The GE IS200EPMCH1A is a power distribution board designed by General Electric for its Mark VI gas turbine control systems. As a crucial part of the control system, it plays a fundamental role in power management within industrial automation setups, especially those related to gas turbine operations.

This board is part of a collection of interconnected components known as the Mark VI power distribution module (PDM). Its main function is to provide core system power for various aspects such as control electronics, I/O contact wetting, and wiring protection. By distributing power effectively, it ensures that all the components within the gas turbine control system receive the appropriate electrical supply to function correctly. This not only helps in maintaining the stability of the control system but also contributes to the overall efficient operation of the gas turbine. Whether it’s powering the sensitive control electronics that regulate the turbine’s operation or providing power for the I/O contacts to interface with other devices, the GE IS200EPMCH1A is at the heart of reliable power delivery in the Mark VI system.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | IS200EPMCH1A |

| Manufacturer | GE |

| Product Type | Power Distribution Board |

| Series | Mark VI |

| Function | Power distribution for control electronics, I/O contact wetting, wiring protection |

| Power Monitoring | Automatically sends power monitoring and diagnostics to the controller |

| Power Segregation | Segregates control and contact wetting power |

| Fault Protection | Proven method with coordinated fault protection and isolation |

| Redundancy | Flexible redundancy strategies for dual or TMR options in most applications |

| Dimensions | Approximately 15×8×1 cm (length × width × height) |

| Weight | 0.1 kg |

| PCI Interface | Compliant with PCI rev 2.2, supports 3.3 V and 5 V signal levels |

IS215WETAH1BB IS200WETAH1AGC

Main Features and Advantages

Automated Power Monitoring and Diagnostics

The GE IS200EPMCH1A has an advanced feature where power monitoring and diagnostics are automatically transmitted to the controller. This eliminates the need for additional human programming and extra I/O modules dedicated to power monitoring. Operations and maintenance teams are promptly alerted to any power – related issues, allowing for quick intervention. For example, if there is a sudden drop in power supply to a critical control component, the system can immediately detect this and notify the relevant personnel, minimizing the risk of system failures.

Power Segregation for Component Protection

It segregates the power for control and contact wetting. This is a crucial advantage as it prevents field wiring problems from causing damage to the sensitive control components. In industrial environments, where electrical interference and wiring issues can be common, this segregation acts as a safeguard. If there is a short – circuit in the contact wetting power circuit, the control components will remain unaffected, ensuring the continued operation of the control system.

Proven Fault Protection and Isolation

The power distribution method employed by the GE IS200EPMCH1A comes with coordinated fault protection and isolation. In the event of a fault, such as an over – current or short – circuit, the board can quickly isolate the affected area, preventing the fault from spreading to other parts of the system. This not only protects the components within the gas turbine control system but also helps in reducing downtime, as the non – affected parts of the system can continue to operate.

Flexible Redundancy Strategies

For applications that require dual or triple – modular redundant (TMR) options, the board offers flexible redundancy strategies. This means that in critical systems where high availability is essential, the GE IS200EPMCH1A can be configured in a redundant setup. If one power distribution board fails, the redundant board can seamlessly take over, ensuring continuous power supply to the gas turbine control system.

IS200AEPAH1ACB

Application Field

Power Generation

In power plants that use gas turbines for electricity generation, the GE IS200EPMCH1A is an essential component. It powers the control electronics that regulate the speed, temperature, and fuel flow of the gas turbine. By ensuring stable power distribution, it helps in maintaining the efficiency of power generation. For instance, in a combined – cycle power plant, the gas turbine’s control system, powered by the GE IS200EPMCH1A, works in tandem with the steam turbine system to optimize overall power production.

Industrial Manufacturing

Industries that use gas turbines for mechanical drive applications, such as in large – scale manufacturing plants, rely on the GE IS200EPMCH1A. For example, in a petrochemical plant, gas turbines may be used to drive compressors that are crucial for the production process. The GE IS200EPMCH1A provides the necessary power for the control system of these gas turbines, ensuring smooth operation and precise control of the mechanical drives.

Aerospace Ground Support

At airports, gas turbines are often used in ground support equipment for aircraft, such as auxiliary power units (APUs). The GE IS200EPMCH1A is used in the control systems of these gas turbines. It powers the electronics that control the start – up, operation, and shutdown of the APUs, ensuring reliable power supply for aircraft systems during ground operations.

Related Products

GE IS200AEADH1ABA

This is a Mark VI board component, similar to the GE IS200EPMCH1A in terms of being part of the Mark VI system. However, it likely has different functions, perhaps related more to specific control or monitoring tasks rather than power distribution like the GE IS200EPMCH1A. It could be used in conjunction with the GE IS200EPMCH1A in a complete Mark VI control system setup.

GE IS200EROCH1ABB

A module for gas turbine control and monitoring. It may interact with the power distribution function of the GE IS200EPMCH1A as it controls and monitors the overall gas turbine operation. While the GE IS200EPMCH1A focuses on power supply, this module manages other aspects like turbine speed control and performance monitoring.

GE IS220PTURH1B

An analog input module. In a gas turbine control system, it can work in tandem with the GE IS200EPMCH1A. The power from the GE IS200EPMCH1A enables this analog input module to receive and process analog signals from various sensors in the gas turbine, such as temperature and pressure sensors.

GE IC690RFH008

A 射频通信模块. It can be part of a larger gas turbine control network where the GE IS200EPMCH1A provides power. This module is used for communication purposes, allowing different components in the control system, which are powered by the GE IS200EPMCH1A, to communicate with each other wirelessly.

GE DS200LDCCH1AGA

A digital controller module. It may use the power supplied by the GE IS200EPMCH1A to perform digital control functions in the gas turbine control system. While the GE IS200EPMCH1A distributes power, this module controls the operation based on digital signals and algorithms.

Installation and Maintenance

Pre – installation preparation: Before installing the GE IS200EPMCH1A, ensure that the installation area is clean and free from dust, moisture, and any potential sources of electrical interference. Verify that the overall Mark VI system is properly configured and that all the necessary connections for power input and output are correctly identified. Check the physical dimensions of the installation location to ensure a proper fit for the board, considering its approximate size of 15×8×1 cm. When handling the board, use appropriate electrostatic discharge (ESD) protection to prevent damage to its sensitive electronic components.

Maintenance recommendations: Regularly inspect the GE IS200EPMCH1A for any signs of physical damage, such as cracks on the board or loose connections. Monitor the power distribution performance by checking the power levels and diagnostic information sent to the controller. Clean the board gently using a soft, dry cloth to remove any dust that may have accumulated over time, as dust can affect heat dissipation and potentially lead to electrical issues. If any power – related problems are detected, refer to the product manual for detailed troubleshooting steps. Additionally, keep track of any software or firmware updates related to the Mark VI system that may affect the operation of the GE IS200EPMCH1A.

Product Guarantee

GE stands firmly behind the quality of the GE IS200EPMCH1A. The product undergoes rigorous quality control procedures during manufacturing to ensure its reliability and performance. GE typically offers a standard warranty period, often around 12 months, for the GE IS200EPMCH1A. During this time, if the board develops any defects in materials or workmanship, GE will provide repair or replacement services. Their dedicated after – sales service team is available to assist customers with any questions regarding installation, operation, or maintenance. GE’s technical experts can offer remote or on – site support, depending on the customer’s needs, to ensure that the GE IS200EPMCH1A continues to function optimally in gas turbine control applications, giving customers confidence in their investment.