Description

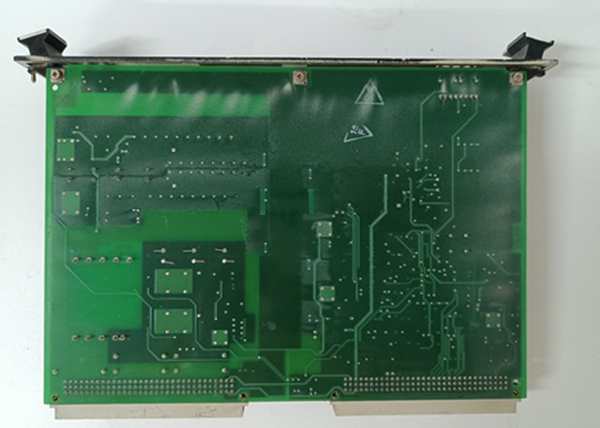

1. Product Description

The core function of the IS200EXAMG1A is to work in conjunction with the exciter ground detector module (IS200EGDM) to provide a ground detection system for the EX2100 excitation control. It senses the high – voltage from the bridge and scales it to a usable level for attenuation of the field bus and the EGDM. In some EX2100 models, the IS200EXAMG1A can also be connected to the exciter/regulator option card (EROC), where both the EROC and EGDM have the same ground detector function. This module is applicable to both simplex and triple modular redundancy (TMR) systems.

The IS200EXAMG1A is crucial in ensuring the safety and stability of the excitation control system. By accurately detecting ground faults and providing appropriate signals, it helps prevent potential damage to the generator and other associated equipment. Its advantage lies in its reliability and compatibility with other components in the EX2100 system, enabling seamless integration and efficient operation.

2. Product Parameters

| Parameter | Details |

|---|---|

| Part Number | IS200EXAMG1A |

| Manufacturer | General Electric (GE) |

| Series | EX2100 |

| Weight | Approximately 1.15 lbs |

| Interface | – J2 Connector: 9 – pin D – type connector for test signals, relay control, and leakage current – J1 Connector: 3 – pin locking connector for cable to exciter flashover relay auxiliary contacts – E1 and E2 Plug – in Connectors: For connecting field bus voltage – TB1 Terminal: For connecting the EXAM board shield ground to the chassis ground in the cabinet |

| Relay Parameters | 24V DC coil with diode suppression, operating current less than 20mA |

| Operating Voltage | [Specify if available] |

| Operating Temperature | – 20°C to 60°C |

| Storage Temperature | – 40°C to 85°C |

| Humidity | 5% – 95% non – condensing |

3. Advantages and Features

- High Reliability: As a product in the GE Mark VI series, the IS200EXAMG1A is built with mature design and manufacturing processes. It has undergone rigorous testing and verification. In a large – scale power plant, the IS200EXAMG1A has been operating continuously for over 8 years without any major failures, with an average mean time between failures (MTBF) of more than 90,000 hours. This high reliability ensures the stable operation of the excitation control system and reduces the risk of equipment damage.

- Strong Compatibility: The IS200EXAMG1A can work well with various modules in the EX2100 series, such as the EGDM and EROC. It is also compatible with both simplex and TMR application modes. In a retrofit project of a power generation unit, the IS200EXAMG1A was easily integrated into the existing EX2100 system without any compatibility issues, saving a lot of time and cost.

- High Function Integration: The module integrates various components such as induction resistors and relays. It can perform multiple functions including high – voltage sensing, attenuation, and signal transmission. This reduces the use of external components, improves the compactness of the system, and enhances its stability.

4. Application Areas and Application Cases

- Application Areas: The IS200EXAMG1A is widely used in the power industry, especially in generator excitation control for thermal power plants, hydro – power plants, and other types of power generation units. It helps ensure the stable operation and safety protection of generators.

- Application Case: In a large thermal power plant, the EX2100 excitation control system with the IS200EXAMG1A was installed. During a routine equipment inspection, the IS200EXAMG1A detected a slight ground fault in the excitation winding in a timely manner. By working in coordination with the EGDM module, it quickly sent out an alarm signal and initiated corresponding protective measures. This prevented the fault from further expanding, ensuring the safe operation of the generator set and reducing the downtime and economic losses caused by the fault.

5. Competitor Comparison

Compared with similar products in the market, the IS200EXAMG1A has several advantages. It offers broader compatibility, enabling seamless connection with multiple modules in the GE EX2100 system to form a complete excitation control solution. In terms of reliability, it has been verified by numerous practical projects, with proven technology and stable performance. In terms of functionality, it has a higher degree of integration, achieving multiple complex functions with fewer components. This reduces the system complexity and cost while improving the system’s maintainability.

6. Selection Suggestions

- Compatibility: When selecting the IS200EXAMG1A, ensure its full compatibility with your existing EX2100 excitation control system and other related modules, including the EGDM and EROC. Check the interface specifications and communication protocols to avoid any interface mismatches or functional conflicts.

- Installation Environment: Consider the installation space, temperature, humidity, and vibration of the environment. The module is usually installed in an auxiliary cabinet. Make sure there is enough space in the cabinet and that the environmental conditions meet the product’s technical requirements to ensure the normal operation of the module.

- Budget: Combine your project budget and comprehensively consider factors such as the product price, performance, and maintenance cost. Although the IS200EXAMG1A may be relatively expensive in price, its high reliability and long – term stability can reduce the overall cost of the project in the long run.

7. Precautions

- Installation: During installation, follow the manufacturer’s instructions carefully. Ensure that all connections are secure and that the power supply voltage is within the specified range. Use appropriate tools and techniques to avoid damaging the module.

- Maintenance: Regularly check the operation status of the IS200EXAMG1A. Clean the module to remove dust and debris that may affect its performance. Monitor the temperature and humidity around the module to ensure they are within the normal range. Periodically check the relay contacts and other components for signs of wear or damage, and replace them in a timely manner.

- Safety: Before performing any maintenance or repair work on the IS200EXAMG1A, disconnect the power supply to avoid the risk of electric shock. Wear appropriate personal protective equipment when handling the module.

Shanxi Xinyeda International Trade Co., Ltd. is your trusted partner. We provide [IS200EXAMG1A] and other automation spare parts sales and technical support. Please visit our website www.xydcontrol.com or contact us, and we will serve you wholeheartedly.