Description

Product Overview

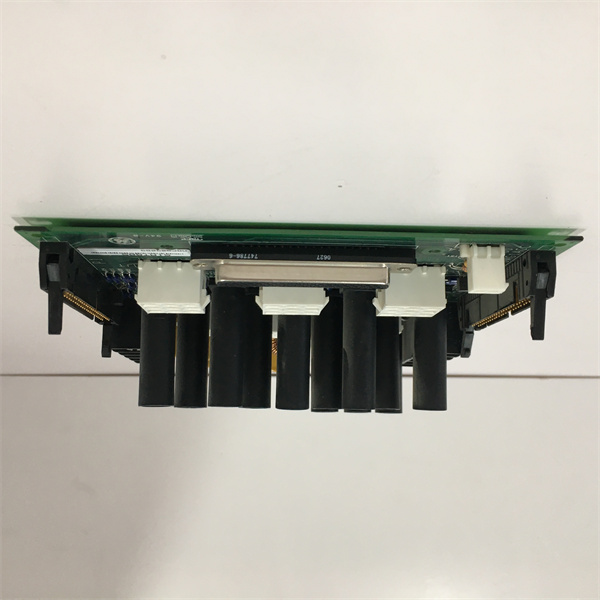

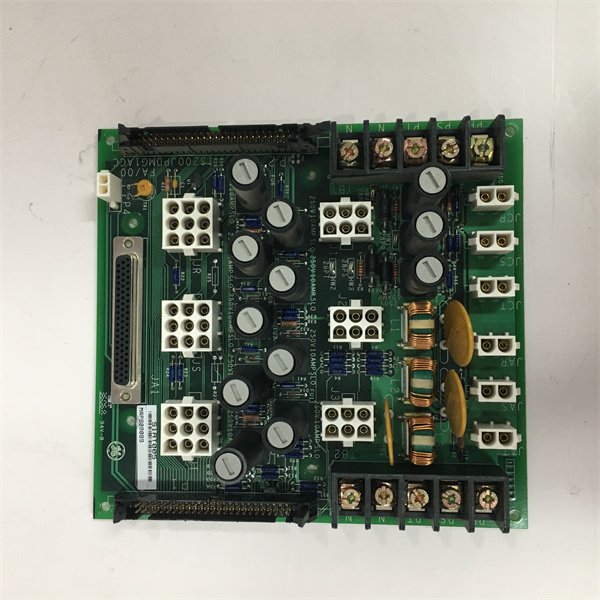

The GE IS200JPDMG1ACC S1AT005 is a high – performance printed circuit board developed by General Electric, a globally recognized leader in industrial automation and power solutions. It is an integral component within the renowned Mark VI Speedtronic turbine control system, which is at the forefront of modern turbine control technology. This system is designed to provide comprehensive control, protection, and monitoring capabilities for a wide range of GE turbines, including those used in gas and steam power generation, as well as mechanical drive applications.

The GE IS200JPDMG1ACC S1AT005 board plays a crucial role in the Mark VI system’s architecture. It is engineered to handle and process various signals, ensuring seamless communication and coordination between different components of the turbine control system. This board is responsible for facilitating the transfer of digital and analog data, enabling precise control over the turbine’s operations. For example, it may receive input signals from sensors that monitor parameters such as temperature, pressure, and rotational speed of the turbine. Based on these inputs, it processes the data and sends out appropriate control signals to actuators, such as valves and governors, to optimize the turbine’s performance.

Technical Specifications

|

Parameter Name

|

Parameter Value

|

|

Product Model

|

IS200JPDMG1ACC S1AT005

|

|

Manufacturer

|

General Electric

|

|

Product Type

|

Printed Circuit Board

|

|

Series

|

Mark VI Speedtronic

|

|

Input Signal Types

|

Multiple (Digital and Analog, depending on application requirements)

|

|

Output Signal Types

|

Multiple (Digital and Analog, for control purposes)

|

|

Operating Voltage

|

[Specified voltage range, check product manual for exact values]

|

|

Power Consumption

|

[Typical power consumption value]

|

|

Communication Interface

|

[List specific communication protocols or interfaces, e.g., Serial, Ethernet]

|

|

Operating Temperature Range

|

– 40 °C to + 70 °C

|

|

Storage Temperature Range

|

– 55 °C to + 85 °C

|

|

Humidity Range

|

5% to 95% non – condensing

|

|

Dimensions (L x W x H)

|

[Provide exact dimensions in millimeters]

|

|

Weight

|

[Specify weight in grams or kilograms]

|

|

Number of Connectors

|

[Number of connectors on the board]

|

|

Connector Types

|

[Describe the types of connectors, e.g., D – Sub, RJ45]

|

|

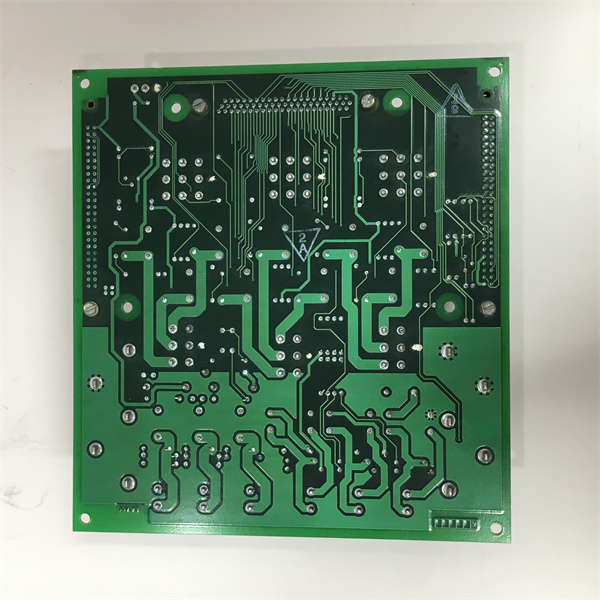

Board Material

|

[Specify the material of the printed circuit board, e.g., FR – 4]

|

IS200JPDMG1ACC S1AT005

Main Features and Advantages

High – Quality Construction: The GE IS200JPDMG1ACC S1AT005 is constructed using high – quality materials, such as a durable FR – 4 printed circuit board material. This ensures its reliability and long – term performance, even in harsh industrial environments. The board’s components are carefully selected and soldered to withstand high temperatures, vibrations, and electrical stress.

Versatile Signal Processing: It has the ability to handle a diverse range of input and output signals, both digital and analog. This versatility allows it to interface with a wide variety of sensors and actuators in the turbine control system. For instance, it can accurately process analog signals from temperature sensors and convert them into digital values for further processing by the control system.

Robust Communication Capabilities: Equipped with specific communication interfaces, this board enables seamless data transfer within the Mark VI system. Whether it’s communicating with other printed circuit boards, controllers, or external devices, the GE IS200JPDMG1ACC S1AT005 ensures fast and reliable data exchange. This is essential for maintaining real – time control and monitoring of the turbine.

Wide Temperature Tolerance: With an operating temperature range of – 40 °C to + 70 °C, the board can be deployed in various geographical locations and industrial settings. From cold regions where gas turbines are used for power generation in winter to hot and humid environments in some industrial plants, the GE IS200JPDMG1ACC S1AT005 can maintain its performance without any degradation.

Compatibility with Mark VI System: As an integral part of the Mark VI Speedtronic turbine control system, it is fully compatible with other components within the system. This compatibility simplifies the installation and integration process, reducing the risk of compatibility issues and ensuring smooth operation of the entire turbine control setup.

Application Field

Power Generation – Gas Turbines: In gas turbine power plants, the GE IS200JPDMG1ACC S1AT005 is used to control and monitor the gas turbine’s operation. It plays a vital role in adjusting the fuel – air mixture ratio, controlling the turbine’s speed, and ensuring efficient power generation. For example, it can receive signals from sensors that detect the temperature of the combustion chamber and adjust the fuel flow accordingly to optimize combustion efficiency.

Power Generation – Steam Turbines: In steam turbine power plants, this board is involved in controlling the steam inlet valves, governing the turbine’s speed, and monitoring various parameters such as steam pressure and temperature. It helps in maintaining the stability and efficiency of the steam turbine, which is crucial for reliable power generation.

Mechanical Drive Applications: In industrial processes where turbines are used for mechanical drive purposes, such as in oil and gas pipelines for pumping operations or in large – scale manufacturing plants for driving machinery, the GE IS200JPDMG1ACC S1AT005 is used to control the turbine’s output torque and speed. It ensures that the turbine provides the necessary mechanical power to drive the equipment efficiently.

IS200JPDMG1ACC S1AT005

Related Products

- GE IS200JPDMG1ADC: This is another printed circuit board within the Mark VI series. While the GE IS200JPDMG1ACC S1AT005 has its specific functions, the GE IS200JPDMG1ADC may have different input/output configurations or processing capabilities. It could be used in similar applications but might be optimized for a different set of signals or control requirements.

- GE Mark VI Controllers: These controllers work in tandem with the GE IS200JPDMG1ACC S1AT005. They send control commands to the board based on the overall control strategy for the turbine. Different models of Mark VI controllers, such as those with varying levels of processing power and communication capabilities, can be used depending on the complexity of the turbine control system.

- GE IS200 Series Sensors: Sensors in the GE IS200 series, like temperature sensors, pressure sensors, and speed sensors, are often used in conjunction with the GE IS200JPDMG1ACC S1AT005. These sensors provide the input signals that the board processes. For example, a temperature sensor may send an analog signal to the board, which is then used to make decisions regarding the turbine’s operation.

- GE IS200 Series Actuators: Actuators in the GE IS200 series, such as valves and governors, receive control signals from the GE IS200JPDMG1ACC S1AT005. Based on the processed data, the board sends out signals to these actuators to adjust the turbine’s operation. For instance, it can send a signal to a steam valve actuator to regulate the steam flow to the turbine.

- GE Power Supplies: Specific power supplies from GE are designed to power the GE IS200JPDMG1ACC S1AT005 and other components in the Mark VI system. These power supplies ensure a stable and reliable power source, which is essential for the proper functioning of the printed circuit board. A well – regulated power supply helps prevent voltage fluctuations that could affect the board’s performance.

Installation and Maintenance

Pre – installation preparation: Before installing the GE IS200JPDMG1ACC S1AT005, ensure that the power to the Mark VI system is turned off to prevent electrical accidents. Check the physical dimensions of the board to ensure it fits correctly in the designated slot within the control cabinet. Verify the compatibility of the board with other components in the system, especially in terms of electrical specifications and communication protocols. Also, carefully read the installation manual provided by GE to understand the correct wiring and connection procedures. Make sure the installation area is clean and free from dust and debris that could potentially affect the board’s performance.

Maintenance recommendations: Regularly inspect the GE IS200JPDMG1ACC S1AT005 for any signs of physical damage, such as cracks in the board, loose connectors, or burnt – out components. Monitor the operating temperature of the board, as overheating can lead to performance degradation or component failure. Use appropriate diagnostic tools to check for any communication errors or abnormal signal readings. If any issues are detected, refer to the troubleshooting section of the product manual. GE also recommends periodic cleaning of the board to remove dust and contaminants that may accumulate over time. Additionally, keep the board’s firmware up – to – date by installing the latest updates provided by GE to ensure optimal performance and compatibility with the Mark VI system.

Product Guarantee

General Electric offers a comprehensive product guarantee for the GE IS200JPDMG1ACC S1AT005. The board undergoes rigorous testing before leaving the factory to ensure it meets high – quality standards. GE provides a standard warranty period, during which, if the board shows any manufacturing defects, they will offer repair or replacement services free of charge. Their team of technical experts is available to offer support for installation, operation, and troubleshooting. In case of any issues, customers can contact GE’s customer service, who will guide them through the process of resolving the problem. GE’s reputation for reliability and quality in the industrial automation industry gives users confidence in the performance and durability of the GE IS200JPDMG1ACC S1AT005 in their turbine control applications.