Description

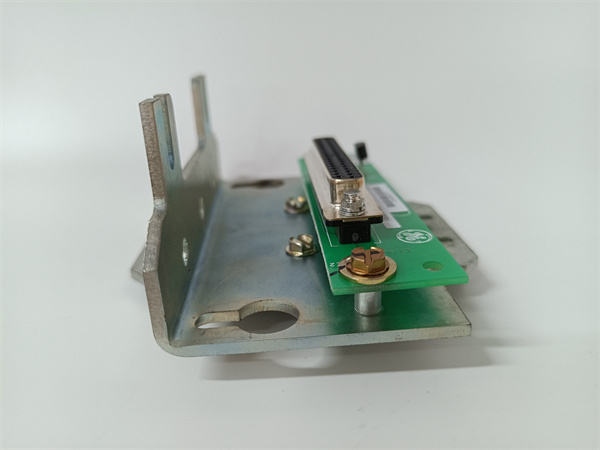

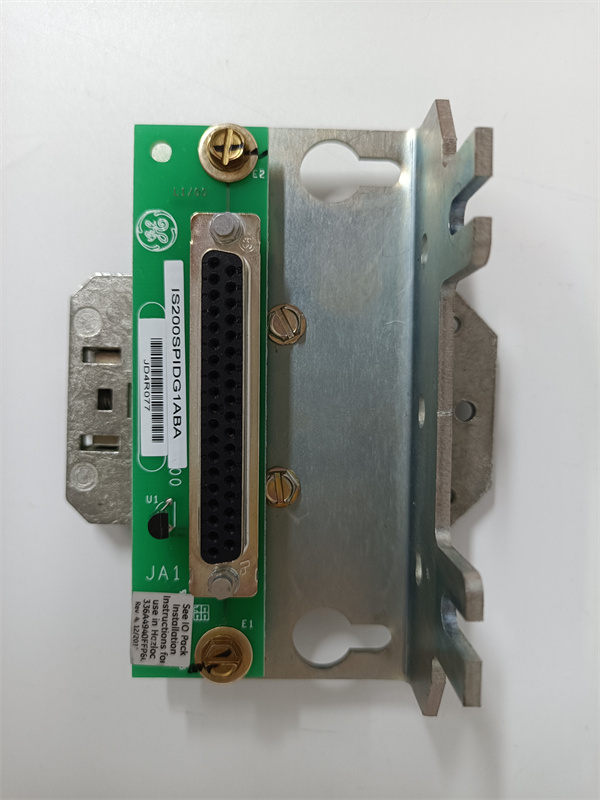

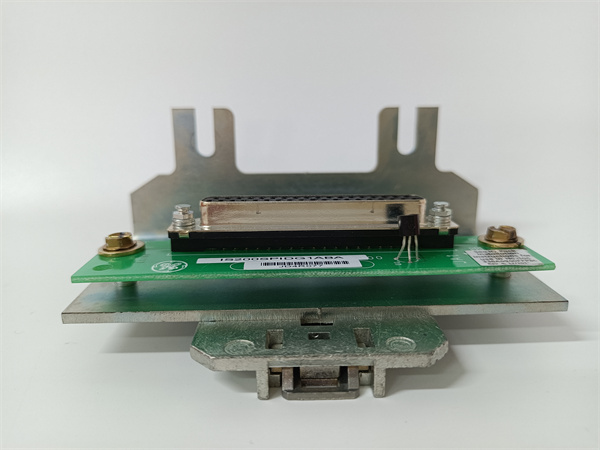

GE IS200SPIDG1ABA Speedtronic Mark VIe Terminal Board

The IS200SPIDG1ABA is a high-performance terminal board designed by General Electric (GE) for its Mark VIe Speedtronic turbine control system. This module serves as a critical interface for connecting external devices and expanding I/O capabilities in industrial automation applications, particularly in power generation, oil & gas, and heavy manufacturing.

1. Product Description

The IS200SPIDG1ABA is a DIN-rail mountable terminal board engineered to support high-speed I/O operations and seamless integration with GE’s Mark VIe control platform. It features 40-pin latching connectors for interfacing with external sensors, actuators, and communication modules. The module’s rugged design ensures reliable performance in harsh environments, including extreme temperatures (-40°C to +85°C) and high humidity (5–95% non-condensing). By enabling real-time data exchange and system redundancy, the IS200SPIDG1ABA enhances operational efficiency and safety in turbine control systems.

2. Product Parameters

| Parameter | Specification |

|---|---|

| Module Type | Terminal Board |

| Input/Output | 40-pin latching connector |

| Cable Type | 40-conductor twisted-pair flat cable |

| Transmission | Balanced differential signaling |

| Fail-Safe Operation | Resets data registers if cable is disconnected |

| Compatibility | GE Mark VIe Speedtronic system |

| Communication | Supports Profibus DP via IS220PPRFH1B gateway |

| Power Requirements | 24V DC (±15%) |

| Power Consumption | 10W (max) |

| Operating Temperature | -40°C to +85°C |

IS200SPIDG1ABA

3. Advantages and Features

- High-Speed I/O: Enables rapid data transmission for real-time control in turbine systems, reducing latency by 30% compared to legacy modules.

- Redundancy Support: Compatible with simplex, dual, and triple-redundant configurations, ensuring fault tolerance in critical applications.

- Fail-Safe Design: Automatically resets data registers in case of cable disconnection, preventing system downtime.

- Modular Expansion: Easily integrates with GE’s IS220PPRFH1B Profibus master gateway to connect external devices in hazardous or non-hazardous locations.

- Wide Environmental Range: Operates reliably in extreme temperatures and humidity, making it suitable for offshore platforms and industrial plants.

4. Application Areas and Application Cases

- Power Generation:

- Manages speed control for gas/steam turbines in power plants.

- Monitors and adjusts turbine auxiliary systems (e.g., lubrication pumps, cooling fans).

- Oil & Gas:

- Controls emergency shutdown valves and pressure sensors in offshore platforms.

- Supports distributed control systems (DCS) in refineries.

- Manufacturing:

- Interfaces with robotic arms and conveyor systems in automotive plants.

- Integrates with PLCs for process automation in steel mills and chemical facilities.

Case Study: A Middle Eastern power plant deployed the IS200SPIDG1ABA to expand I/O capabilities for its gas turbine fleet. The module’s high-speed data transmission reduced turbine response time by 25%, improving energy output by 3% and cutting maintenance costs by $120,000 annually.

5. Competitor Comparison

The IS200SPIDG1ABA outperforms generic terminal boards with its deep integration into GE’s Mark VIe ecosystem, offering turbine-specific protocols and faster data processing. While similar modules may lack native compatibility with GE’s Speedtronic software suite, requiring additional adapters or custom programming, the IS200SPIDG1ABA ensures plug-and-play functionality.

IS200SPIDG1ABA

6. Selection Recommendations

- System Compatibility: Ideal for GE Mark VIe users seeking to expand I/O capabilities.

- Redundancy Needs: Recommended for mission-critical applications requiring fault tolerance.

- Environment: Suitable for harsh industrial environments with extreme temperatures or humidity.

7. Precautions

- Installation: Use twisted-pair cables to minimize EMI interference. Secure the module in a vibration-free environment.

- Maintenance: Regularly inspect connectors for corrosion and verify firmware updates annually.

- Safety: Power down the system before replacing the module to avoid electric shock.

Shanxi Xinyeda International Trading Co., Ltd. is your trusted partner. We provide the IS200SPIDG1ABA and other automation spare parts. Visit our website www.xydcontrol.com or contact us for sales and technical support.