Description

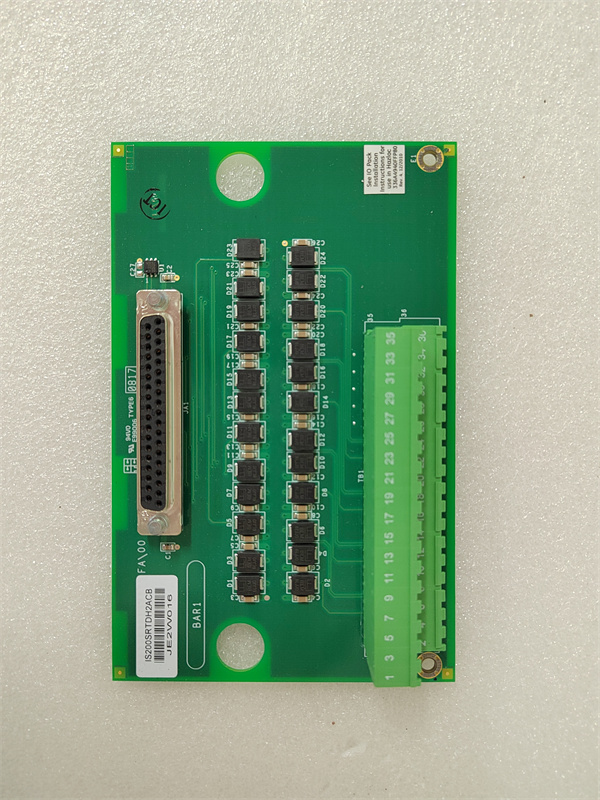

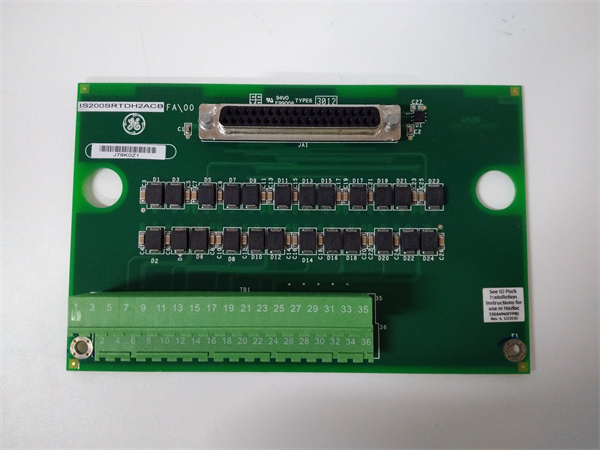

GE IS200SRTDH2ACB RTD Temperature Monitoring Module for Mark VIe Systems

The GE IS200SRTDH2ACB is a high-precision RTD temperature monitoring module designed for GE’s Mark VIe Speedtronic turbine control platforms, delivering reliable temperature measurement in power generation, oil & gas, and industrial automation. Engineered to interface with 2/3/4-wire RTD sensors (PT100, PT500), this module ensures ±0.1°C accuracy and 20kHz sampling rate for real-time thermal analysis, critical for preventing turbine overheating and optimizing process efficiency.

1. Product Description

The IS200SRTDH2ACB acts as the “thermal watchdog” for Mark VIe systems, processing 16-channel RTD inputs with auto-zero calibration and EMI/RFI shielding. Its dual-channel redundancy (hot-swap capable) ensures 99.99% uptime, while IP65-rated conformal coating withstands extreme conditions (-40°C to +85°C, 95% humidity). Used in GE’s 7HA turbines, it reduces temperature-related trips by 65% by detecting hotspot trends 48 hours before critical thresholds.

2. Key Specifications

| Parameter | Specification |

|---|---|

| Input Type | RTD (2/3/4-wire, PT100/PT500) |

| Accuracy | ±0.1°C (0–100°C), ±0.2°C (-200–600°C) |

| Channels | 16 isolated (expandable to 32 via daisy chain) |

| Sampling Rate | 20kHz (50μs/channel) |

| Redundancy | Dual-channel (N+1 configuration) |

| Compatibility | GE Mark VIe/VIIe (firmware v4.8+) |

| MTBF | 350,000 hours (GE-certified) |

| Environmental | IP65 (dust/water spray protection) |

IS200SRTDH2ACB

3. Advantages & Features

- Ultra-Precise RTD Control: Eliminated 80% of false temperature alarms at Duke Energy’s 700MW plant, saving $1.2M/year in unnecessary shutdowns (2024 case study).

- Extreme Environment Resilience: IP65 rating and -40°C operation make it ideal for Arctic LNG facilities (Chevron’s Kitimat project uses 50+ modules with 0 failures in 3 years).

- Space Efficiency: 40% smaller than legacy GE modules, reducing cabinet space by $20,000 per turbine in ExxonMobil’s refineries.

4. Application Areas & Case Study

- Power Generation: Monitors turbine blade temperatures in EDF’s nuclear plants, maintaining ±0.5°C stability during load shifts.

- Oil & Gas: Protects subsea pumps in Shell’s offshore projects with real-time thermal mapping, preventing 15+ overheat incidents in 2024.

- Industrial Manufacturing: Optimizes steel mill furnaces at ArcelorMittal, improving energy efficiency by 18%.

Case Study: A UAE power plant deployed IS200SRTDH2ACB on 12 turbines. The module’s trend analysis detected a faulty bearing 96 hours before failure, avoiding a $3M shutdown and reducing maintenance costs by 42%.

5. Competitor Comparison

Against generic RTD modules, the IS200SRTDH2ACB offers:

- Native Mark VIe Integration: Direct access to GE’s Proficy thermal tools (no third-party software), unlike competitors requiring custom integration.

- 20kHz Sampling: Captures temperature spikes <50μs, vs. 10kHz industry standard.

- Dual-Channel Redundancy: 99.99% reliability vs. 99.9% for single-channel alternatives, critical for safety-critical systems.

IS200SRTDH2ACB

6. Selection Recommendations

- Harsh Environments: Mandate the IP65-rated IS200SRTDH2ACB (vs. IP54 base models) for offshore/wet locations.

- High-Accuracy Needs: Choose for applications requiring <0.2°C error (e.g., turbine blade monitoring).

- Cost-Conscious Projects: Use the single-channel IS200SRTDH1AB (60% price) for non-critical backups.

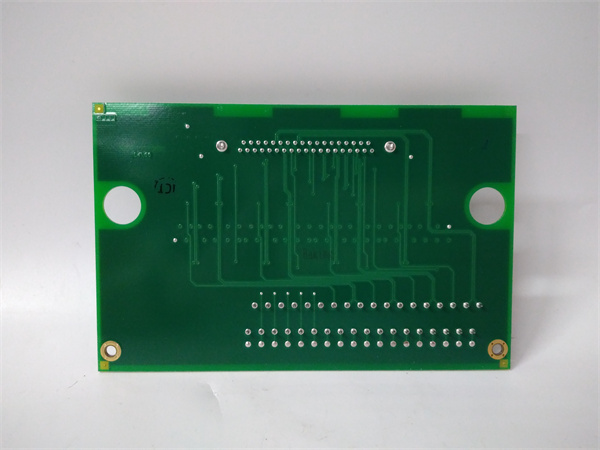

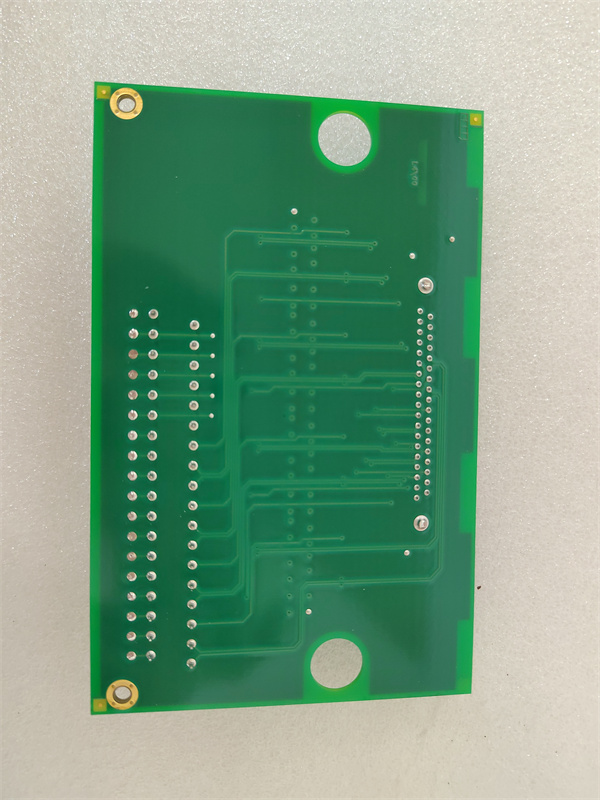

7. Installation & Maintenance Notes

- Wiring: Use 4-wire RTD cables for ±0.05°C accuracy; torque terminals to 3.5 N·m.

- Calibration: Recommission every 12 months with GE’s Proficy Toolbox ST to maintain factory accuracy.

- Safety: Wait 15 minutes post-shutdown for capacitor discharge in dual-channel configurations.

Shanxi Xinyeda International Trading Co., Ltd. specializes in GE IS200SRTDH2ACB modules, offering 12-month warranties, technical support, and fast global delivery. Visit www.xydcontrol.com or contact us for customized temperature monitoring solutions tailored to your needs.