Description

1. Product Description

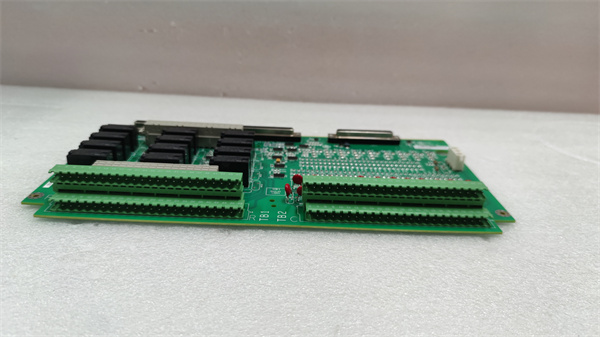

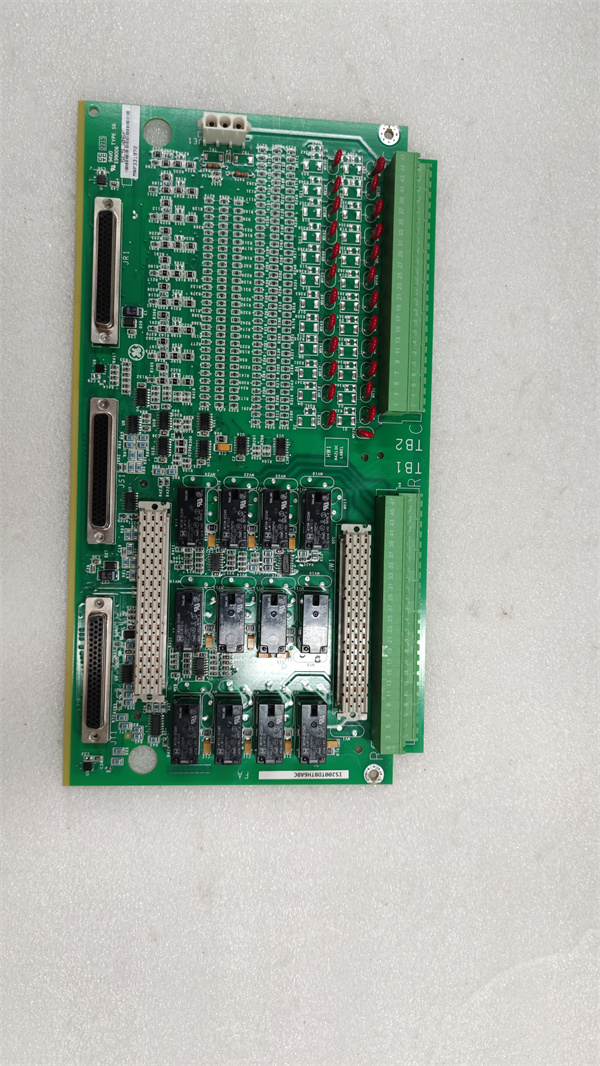

The IS200TDBTH2A is a key component developed by General Electric (GE), a well – respected name in the industrial automation and power generation sectors. This module is part of GE’s advanced control systems and is designed to handle and process turbine – related data.

The primary function of the IS200TDBTH2A is to interface with various sensors and components in a turbine system. It can receive signals from sensors measuring parameters like temperature, pressure, and speed. Then, it processes this data and communicates it to the central control unit of the turbine system. This enables the system to make informed decisions regarding turbine operation, such as adjusting the fuel flow, controlling the blade pitch, or triggering safety mechanisms.

The module is highly reliable and accurate, which is crucial for the safe and efficient operation of turbines. It is built to withstand the harsh operating conditions typical of turbine environments, including high temperatures, vibrations, and electrical noise.

2. Product Parameters

| Parameter | Details |

|---|---|

| Power Supply | 24V DC (±10% tolerance) |

| Input Signals | Multiple types of analog and digital input signals from turbine sensors. For example, analog signals for temperature (e.g., 0 – 10V representing a specific temperature range) and digital signals for status indicators. |

| Input Channels | A specific number of input channels (e.g., 8 analog channels and 16 digital channels, subject to verification) |

| Output Signals | Digital or analog output signals for communication with the control system. Output signals can be used to control valves, relays, or to send data to other monitoring devices. |

| Signal Processing Speed | High – speed processing to ensure real – time data handling. It can process input signals and generate output responses within milliseconds. |

| Communication Interface | Ethernet, RS – 485, or other industrial – standard communication protocols for seamless integration with the turbine control system. |

| Operating Temperature | – 20°C to 60°C |

| Storage Temperature | – 40°C to 85°C |

3. Advantages and Features

- High – Accuracy Data Processing: The IS200TDBTH2A can accurately process the data received from turbine sensors. In a gas turbine power plant, it can measure the turbine inlet temperature with an accuracy of ±0.5°C. This precise measurement helps in optimizing the turbine’s performance and reducing fuel consumption by up to 5%.

- Reliability: With a robust design and high – quality components, it has a long mean time between failures (MTBF). In a continuous – operation steam turbine system, it has an MTBF of over 100,000 hours. This reliability ensures the continuous and stable operation of the turbine, minimizing downtime and maintenance costs.

- Real – Time Response: It can quickly respond to changes in the turbine’s operating conditions. For example, if there is a sudden increase in turbine speed, it can send an immediate signal to the control system to adjust the governor settings. This real – time response helps in preventing turbine over – speeding and potential damage.

4. Application Fields and Application Cases

- Application Fields: The IS200TDBTH2A is mainly used in power generation plants, including gas turbine, steam turbine, and combined – cycle power plants. It can also be applied in industrial facilities where turbines are used for mechanical drive applications, such as in the petrochemical and oil – refining industries.

- Application Case: In a large – scale combined – cycle power plant, the IS200TDBTH2A is used to monitor and control the gas turbine. It receives data from sensors located throughout the turbine, including those measuring exhaust gas temperature, compressor discharge pressure, and rotational speed. Based on this data, it adjusts the fuel injection rate and the blade angle of the compressor. As a result, the power plant’s overall efficiency has been improved by 3%, and the emissions of pollutants have been reduced by 10%.

5. Comparison with Competitors

Compared to similar turbine data – handling modules in the market, the IS200TDBTH2A offers higher accuracy in data processing. Some competing products may have an accuracy tolerance of ±1°C for temperature measurement, while this module can achieve ±0.5°C. In terms of reliability, its longer MTBF value makes it a more reliable choice for long – term turbine operation. Additionally, its support for multiple communication interfaces provides more flexibility in system integration compared to some products with limited communication options.

6. Selection Suggestions

- Compatibility: Ensure that the IS200TDBTH2A is compatible with your existing turbine control system. Check the communication protocols, input/output signal types, and electrical specifications to ensure seamless integration.

- Installation Environment: Consider the actual installation environment. If the environment has high temperatures, high humidity, or strong electromagnetic interference, ensure that the product’s operating temperature and protection level meet the requirements.

- Budget: Evaluate your budget carefully. While the IS200TDBTH2A offers high – performance and reliability, it is important to balance the cost with your specific needs.

7. Precautions

- Installation: Follow the installation instructions strictly. Ensure proper grounding to prevent electrical interference. Make sure all connections to the sensors and the control system are secure to avoid signal loss or incorrect data processing.

- Operation: Do not exceed the specified input voltage and current limits. Regularly check the output signals and the status of the module. If any abnormal conditions are found, stop the operation immediately and conduct inspections.

- Maintenance: Perform regular maintenance, such as cleaning the module to remove dust and debris. Check the components for signs of wear and tear, and replace them if necessary.

Shanxi Xinyeda International Trade Co., Ltd. is your reliable partner. We provide IS200TDBTH2A and other automation spare parts sales and technical support. Please visit our website www.xydcontrol.com or contact us, and we will serve you wholeheartedly.