Description

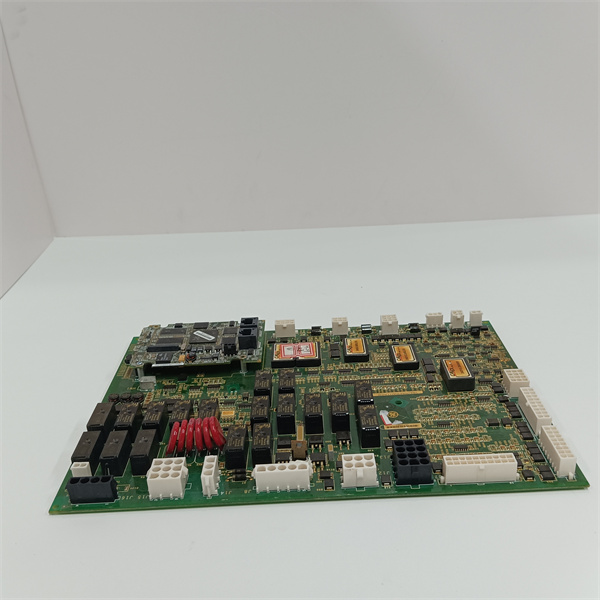

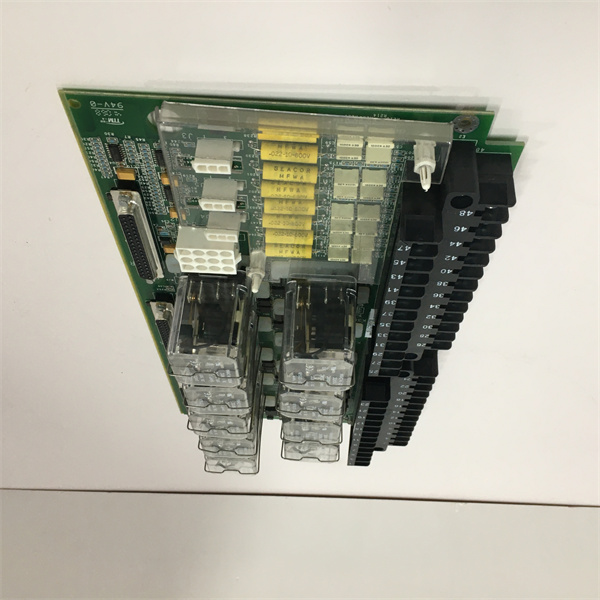

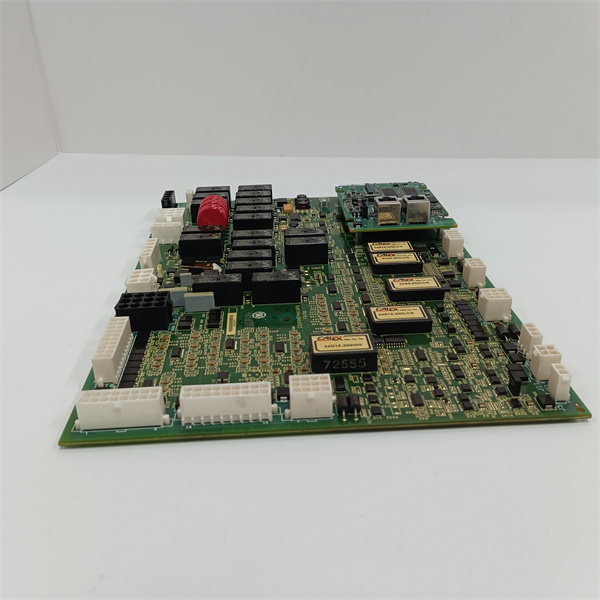

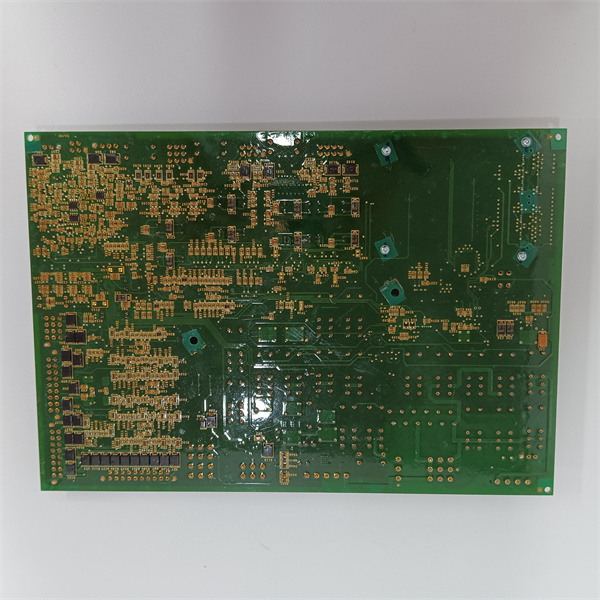

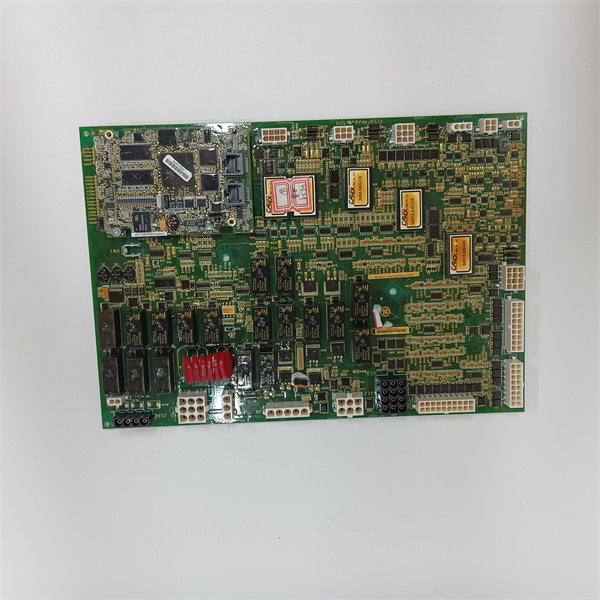

Product Overview

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | IS200TPROH1BBB |

| Manufacturer | GE |

| Product Type | Protection Terminal Board |

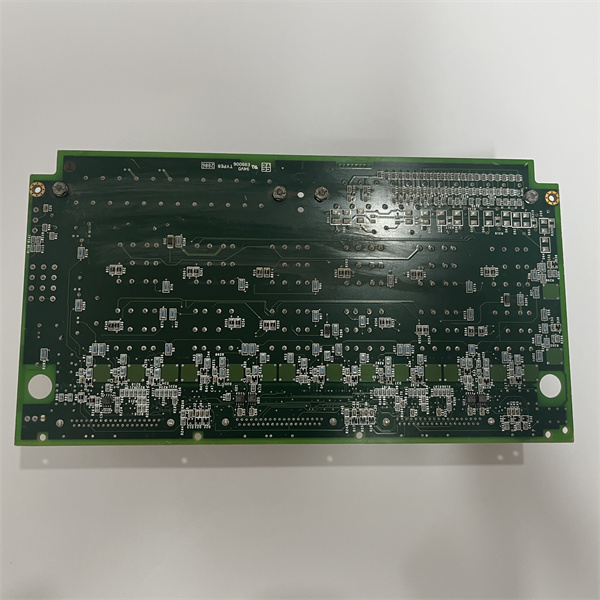

| Board Material | Printed Circuit Board (PCB) |

| Component Count | Multiple (including various-sized electronic components) |

| Connector Type | Specific connectors for signal input/output |

| Operating Voltage | [Specify voltage range if available] |

| Operating Temperature | [Specify temperature range] |

| Dimensions | [Length] x [Width] x [Height] (to be specified accurately) |

| Weight | [Weight value] |

| Mounting Method | [Describe mounting method] |

| Compatibility | Compatible with Mark VI series components |

IS200AEPAH1ACB

Main Features and Advantages

Integrated Design: It features an integrated design that allows for seamless integration within the Mark VI series. This integration simplifies the overall system architecture, making installation and maintenance more straightforward. All components on the IS200TPROH1BBB are carefully arranged to optimize signal transmission and control.

Customizable Functionality: With a variety of electronic components, the IS200TPROH1BBB can be customized to meet specific application requirements. Different settings and configurations can be adjusted to adapt to various turbine control scenarios, providing flexibility for users in different industrial settings.

Application Field

Power Generation: In power plants that use gas or steam turbines, the IS200TPROH1BBB is used to manage and automate turbine operations. It helps in controlling the start-up, shut-down, and continuous operation of the turbines, ensuring stable power generation.

Industrial Manufacturing: Industries that rely on steam or gas turbines for their manufacturing processes, such as chemical plants and refineries, utilize the IS200TPROH1BBB to regulate the turbines. This ensures the efficient supply of power and heat for manufacturing operations.

Energy Management Systems: In large-scale energy management systems where multiple turbines are interconnected, the IS200TPROH1BBB plays a role in coordinating the operation of individual turbines. It enables effective monitoring and control, optimizing energy production and distribution.

IS200AEPAH1ACB

Related Products

Mark VI Series Controllers: These are the main controllers that work in tandem with the IS200TPROH1BBB to manage all aspects of turbine operation, providing overall system control.

GE Turbine Sensors: These sensors are used in conjunction with the IS200TPROH1BBB to gather data on turbine conditions, such as temperature, pressure, and vibration, which is then processed by the terminal board.

IS200 Series Boards: Other boards in the IS200 series may have complementary functions, such as signal amplification or data storage, and can be used together with the IS200TPROH1BBB in a comprehensive turbine control system.

GE Power Module for Turbines: This power module provides the necessary electrical power to the IS200TPROH1BBB and other components in the turbine control system, ensuring stable operation.

Installation and Maintenance

Maintenance recommendations: Regularly inspect the IS200TPROH1BBB for any signs of physical damage, such as cracks or loose components. Clean the board gently to remove dust that could affect its performance. Periodically check the electrical connections to ensure they are secure. If any issues are detected, refer to the GE product manual for troubleshooting steps or contact GE’s technical support.