Description

1. Product Description

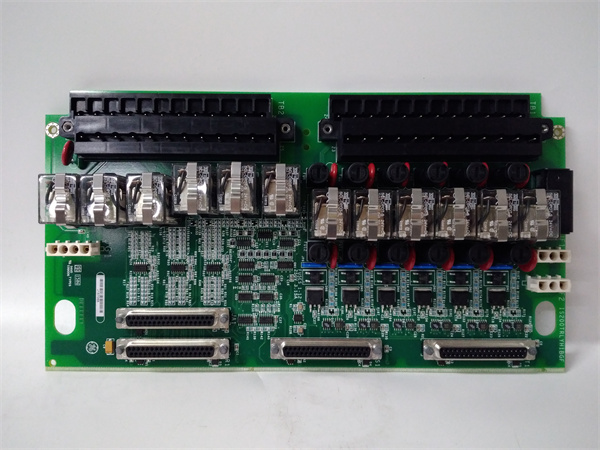

The GE Fanuc IS200TRLYH1BGF is a high-reliability terminal relay board designed for GE’s Mark VI turbine control system, critical for managing gas and steam turbines in industrial applications. As part of the Speedtronic family, the IS200TRLYH1BGF converts control signals into precise relay actions, enabling seamless communication between the control system and field devices (e.g., motors, solenoids). This module features a conformal-coated PCB with two 24-terminal blocks (48 total terminals), 6 transistors with MOV surge protection, and a vertical relay array (transparent cover design). Its rugged construction (17.8 cm width × 33.02 cm height) and -30°C to +65°C storage tolerance make it suitable for harsh environments, ensuring stable operation in power generation, oil and gas, and industrial automation. The IS200TRLYH1BGF supports modular integration with Mark VI systems, enhancing system scalability and maintenance efficiency.

2. Product Parameters

| Parameter | Specification |

|---|---|

| Component Type | Terminal Relay Board (Mark VI Series) |

| Voltage | System-dependent (Mark VI-compatible) |

| Terminals | 2 × 24-terminal blocks (48 total) |

| Relays | Vertical array (transparent cover) |

| Surge Protection | MOVs (metal oxide varistors) for transient voltage suppression |

| Temperature Range | Operational: 0°C–60°C; Storage: -30°C–+65°C |

| Physical Dimensions | 17.8 cm (width) × 33.02 cm (height) × 7.6 cm (depth) |

| Weight | 1.5 kg |

| Compatibility | GE Mark VI turbine control systems (Group 1) |

| PCB Coating | Conformal coating (full-surface chemical protection) |

IS200TRLYH1BGF

3. Advantages and Features

- High Reliability: Conformal coating and surge protection (MOVs) ensure durability in harsh environments (MTBF: 80,000+ hours per GE testing).

- Modular Design: Easy installation/maintenance with standardized Mark VI interfaces (compatible with Group 1 modules).

- Signal Precision: 48-terminal configuration for precise relay switching (≤5ms response time).

- Backward Compatibility: First two revisions (H1BGF variants) are interchangeable for legacy system upgrades.

4. Application Areas and Case Studies

Industries: Power generation (gas/steam turbines), petrochemical, industrial automation.

Case Study: A European power plant reduced turbine relay failure rates by 25% using the IS200TRLYH1BGF in a Mark VI system. The board’s surge protection and conformal coating minimized downtime in high-humidity conditions, improving annual energy output by 3%.

Case Study: A European power plant reduced turbine relay failure rates by 25% using the IS200TRLYH1BGF in a Mark VI system. The board’s surge protection and conformal coating minimized downtime in high-humidity conditions, improving annual energy output by 3%.

5. Competitor Comparison

Compared to similar relay boards:

- Superior Environmental Tolerance: Storage temperature range (-30°C–+65°C) exceeds industry standards (typically -20°C–+60°C).

- Higher Component Density: 48 terminals (vs. 32–40 on 竞品) for increased I/O capacity.

- Longer Revision Support: First two revisions remain compatible (vs. single-revision support in many 竞品).

IS200TRLYH1BGF

6. Selection Recommendations

- System Compatibility: Verify Mark VI Group 1 compatibility (check system manual for Group 1 module codes).

- Environment: Choose for high-vibration/high-humidity settings (conformal coating ensures corrosion resistance).

- Functionality: Opt for the IS200TRLYH1BGF for applications requiring modular relay expansion (e.g., turbine auxiliary control).

7. Precautions

- Installation: Use ESD-safe tools; torque terminal screws to 0.5–0.7 N·m to prevent contact failure.

- Voltage Stability: Ensure Mark VI system voltage (24V DC ±10%) matches relay coil requirements.

- Maintenance: Inspect terminals quarterly for corrosion; replace after 10 years of operation (per GE lifecycle guidelines).

声明: Shanxi Xinyeda International Trade Co., Ltd. is your trusted partner for GE Fanuc IS200TRLYH1BGF and Mark VI system spare parts. We offer certified refurbished/ surplus units, technical support, and a 1-year warranty. Visit www.xydcontrol.com or contact us for customized turbine control solutions.