Description

Product Overview

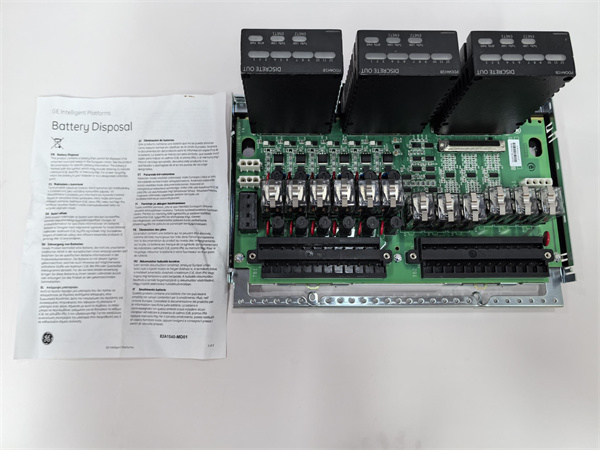

The General Electric IS200TRLYH1BHH is a pivotal termination relay card within the renowned Mark VI turbine control system. As part of GE’s high – performance product lineup for industrial control, this card is designed to offer reliable relay – based control and signal handling capabilities. It serves as a crucial link between different components in the Mark VI system, ensuring seamless communication and accurate control actions.

The GE IS200TRLYH1BHH features voted coil drive feedback, which adds an extra layer of reliability to the relay operations. It houses socketed sealed mechanical relays, providing stable and long – lasting performance even in harsh industrial environments. The inclusion of MOV (Metal Oxide Varistor) suppression helps in protecting the card and connected components from voltage spikes. With 48 barrier terminals, it offers ample connection points for various wiring requirements, making it suitable for complex control setups. This module plays a fundamental role in applications where precise control of electrical signals is essential, such as in power generation and industrial automation processes that rely on the Mark VI turbine control system.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | IS200TRLYH1BHH |

| Manufacturer | General Electric |

| Product Type | Termination Relay Card |

| Series | Mark VI |

| Relay Configuration | 12 form C relays, with ratings of 24 VDC 3 A, 125 VDC 6 A, 120/240 VAC 3A |

| Power Distribution | 6 fused branches, 1 special unfused |

| Coil Drive | Voted coil drive feedback |

| Relay Type | Socketed sealed mechanical relays |

| Over – voltage Protection | MOV suppression |

| Terminal Count | 48 barrier terminals |

| Power Supply Options | Standard 125V DC or 115/230V AC, optional 24V DC |

| System Compatibility | Compatible with simplex and triple modular redundant (TMR) applications |

| Response Time | Maximum 25ms |

| Operating Temperature | – 10 °C to + 55 °C |

| Dimensions | Approximately 33 cm x 17.8 cm x 5.5 cm |

| Weight | 1.42 kg |

IS200TRLYH1BHH

Main Features and Advantages

Reliable Relay Performance

The GE IS200TRLYH1BHH is equipped with 12 form C relays, which are designed to handle different voltage and current ratings. These relays can be configured to drive external solenoids or provide dry, form – C contact outputs. Their reliable switching action, with a maximum response time of 25ms, ensures that control signals are transmitted accurately and promptly, minimizing any potential delays in the control system.

Enhanced Protection

The MOV suppression feature is a key advantage. In industrial environments, voltage spikes are common due to electrical disturbances, motor startups, or lightning strikes. The MOVs on the IS200TRLYH1BHH quickly divert excess voltage, protecting the relays and other sensitive components on the card. This not only extends the lifespan of the card but also safeguards the connected equipment from damage caused by over – voltage events.

Versatile Power Supply Options

With the ability to operate on standard 125V DC or 115/230V AC, and an optional 24V DC power supply, the GE IS200TRLYH1BHH offers great flexibility. This allows it to be integrated into a wide range of existing industrial control systems, regardless of their power supply configurations. The individual jumper – selectable fuses further enhance safety by protecting against over – current situations in each power supply branch.

Compatibility with Redundant Systems

The card’s compatibility with both simplex and triple modular redundant (TMR) applications makes it suitable for critical industrial applications where high availability is a must. In TMR systems, the IS200TRLYH1BHH can work in tandem with other redundant components to ensure that the control system continues to operate even in the event of a component failure. This redundancy feature significantly improves the overall reliability of the industrial control setup.

Application Field

Power Generation

In power generation plants, especially those using gas or steam turbines, the GE IS200TRLYH1BHH is widely used. It controls various aspects of the turbine operation, such as the opening and closing of valves, starting and stopping of auxiliary equipment, and monitoring of safety – related signals. For example, it can be used to control the fuel supply solenoids in a gas turbine, ensuring that the fuel is delivered precisely according to the control system’s commands. In steam turbines, it may be used to control the operation of condensate pumps or cooling water valves, maintaining optimal operating conditions for efficient power generation.

Industrial Automation

In industrial automation settings, the IS200TRLYH1BHH is used to interface between the control system and the actuators. In a manufacturing plant with automated production lines, it can control the operation of pneumatic or hydraulic cylinders, which are used to move parts, operate machinery, or perform assembly tasks. It can also be used to control the on – off operation of motors, conveyor belts, and other electrical equipment, ensuring smooth and coordinated operation of the entire production process.

Energy Sector

Beyond power generation, in the broader energy sector, such as oil and gas production facilities, the GE IS200TRLYH1BHH plays a crucial role. It can be used to control the operation of pumps, compressors, and valves in oil pipelines or gas processing plants. For instance, in a gas compressor station, it can control the starting and stopping of compressors based on pressure and flow rate signals, ensuring efficient gas transportation and processing.

IS200TRLYH1BHH

Related Products

IS200TRLYH1B: This is a closely related version of the IS200TRLYH1BHH. While the basic functionality of providing relay – based control in the Mark VI system remains the same, the IS200TRLYH1B may have some differences in terms of specific component ratings or minor design details. It could be a more basic or an earlier iteration of the product, suitable for applications where the enhanced features of the IS200TRLYH1BHH are not required.

PDOA/YDOAI/O Pack: This I/O pack is designed to work in conjunction with the GE IS200TRLYH1BHH. It provides additional input and output capabilities to the overall control system. When used together, they expand the range of signals that can be processed and controlled, enabling more complex industrial control applications. The IS200TRLYH1BHH can receive signals from the I/O pack and use its relay functions to actuate external devices based on those signals.

Other Modules in the Mark VI Series: Modules like the control processors and various sensor interface modules in the Mark VI series work in harmony with the IS200TRLYH1BHH. The control processors send control commands to the IS200TRLYH1BHH based on the data received from sensor interface modules. For example, a temperature sensor interface module may send temperature data to the control processor, which then decides, based on predefined setpoints, to send a control signal to the IS200TRLYH1BHH to actuate a cooling fan or a heater.

GE Speedtronic Control System Components: The IS200TRLYH1BHH is an integral part of the GE Speedtronic control system. Other components in this system, such as the operator interfaces, communication modules, and power supply units, all contribute to the overall functionality. The power supply units provide the necessary power to the IS200TRLYH1BHH, while the operator interfaces allow operators to monitor and adjust the settings related to the relay operations through the control system.

IS200TRLYH1BGF: Similar to the IS200TRLYH1BHH, the IS200TRLYH1BGF is also a relay – related module. It may have different voltage input and output capabilities or additional features tailored for specific applications. For example, it could be optimized for applications where a different set of voltage levels for the relays is required, or it may have enhanced diagnostic capabilities compared to the IS200TRLYH1BHH.

PDOA/YDOAI/O Pack: This I/O pack is designed to work in conjunction with the GE IS200TRLYH1BHH. It provides additional input and output capabilities to the overall control system. When used together, they expand the range of signals that can be processed and controlled, enabling more complex industrial control applications. The IS200TRLYH1BHH can receive signals from the I/O pack and use its relay functions to actuate external devices based on those signals.

Other Modules in the Mark VI Series: Modules like the control processors and various sensor interface modules in the Mark VI series work in harmony with the IS200TRLYH1BHH. The control processors send control commands to the IS200TRLYH1BHH based on the data received from sensor interface modules. For example, a temperature sensor interface module may send temperature data to the control processor, which then decides, based on predefined setpoints, to send a control signal to the IS200TRLYH1BHH to actuate a cooling fan or a heater.

GE Speedtronic Control System Components: The IS200TRLYH1BHH is an integral part of the GE Speedtronic control system. Other components in this system, such as the operator interfaces, communication modules, and power supply units, all contribute to the overall functionality. The power supply units provide the necessary power to the IS200TRLYH1BHH, while the operator interfaces allow operators to monitor and adjust the settings related to the relay operations through the control system.

IS200TRLYH1BGF: Similar to the IS200TRLYH1BHH, the IS200TRLYH1BGF is also a relay – related module. It may have different voltage input and output capabilities or additional features tailored for specific applications. For example, it could be optimized for applications where a different set of voltage levels for the relays is required, or it may have enhanced diagnostic capabilities compared to the IS200TRLYH1BHH.

Installation and Maintenance

Pre – installation preparation: Before installing the GE IS200TRLYH1BHH, ensure that the power to the entire Mark VI control system is switched off to prevent electrical accidents. Thoroughly inspect the card for any visible signs of damage during transit, such as bent pins, cracked circuit boards, or loose components. Verify the compatibility of the IS200TRLYH1BHH with the existing Mark VI system components, including the power supply voltage and the type of I/O pack it will be connected to. Identify the appropriate slot or mounting location within the control panel, following the system’s installation guidelines. Prepare all the necessary wiring materials and tools, such as cables, wire strippers, and crimping tools.

Maintenance recommendations: Regularly check the GE IS200TRLYH1BHH for any loose connections. Vibration in industrial environments can cause wires to become loose over time, leading to intermittent or incorrect operation. Inspect the relays for any signs of wear, such as pitted contacts or abnormal noise during operation. Clean the card periodically to remove dust and debris, which can accumulate and affect the performance, especially in high – humidity or dusty environments. Use appropriate cleaning tools, like compressed air or a soft, lint – free brush, to avoid electrostatic discharge. Monitor the operating temperature of the card. If it exceeds the specified range of – 10 °C to + 55 °C, it could indicate a problem, such as a cooling issue or a malfunctioning component. In case of any abnormal behavior, such as incorrect relay switching or unexpected power consumption, refer to the product manual’s troubleshooting section or contact GE’s technical support for assistance.

Product Guarantee

General Electric offers a comprehensive product guarantee for the GE IS200TRLYH1BHH. The product undergoes strict quality control procedures during manufacturing to meet high – industry standards. GE provides a warranty that covers any manufacturing defects that may occur during the specified warranty period. In case of such defects, they will promptly provide repair or replacement services. Their team of experienced technical experts is available to offer technical support for installation, operation, and troubleshooting. This commitment reflects GE’s confidence in the reliability and performance of the IS200TRLYH1BHH, giving customers peace of mind when integrating this module into their industrial control systems. Whether it’s for new installations or system upgrades, customers can rely on GE’s support to ensure the long – term and trouble – free operation of the IS200TRLYH1BHH.