Description

Product Overview

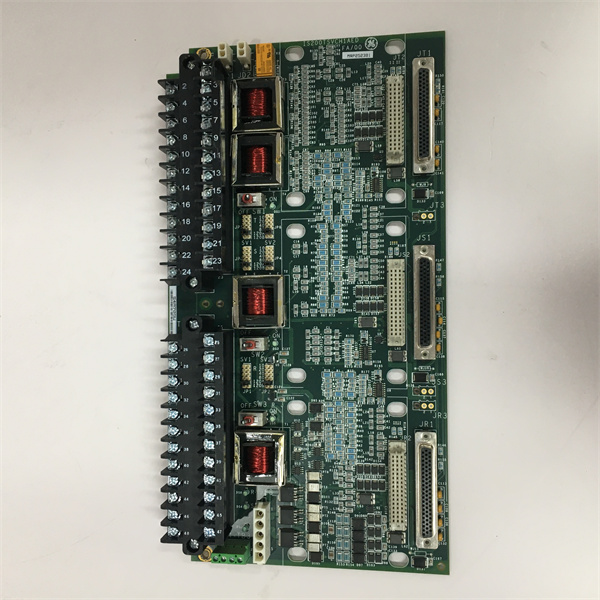

The GE IS200TSVCH1AED is a pivotal terminal board that is an integral part of the GE Speedtronic Mark VI system, a sophisticated platform designed for the management of gas and steam turbines. As a key component, the GE IS200TSVCH1AED is engineered to facilitate seamless data transmission and monitoring within the automation ecosystem. Its core function lies in enabling communication between different elements of the system, ensuring that critical data related to turbine operations is accurately processed and transmitted.

Positioned as a reliable and efficient solution for industrial control applications, the GE IS200TSVCH1AED plays a crucial role in enhancing the overall performance and reliability of the Speedtronic Mark VI system. By providing essential connectivity and data management capabilities, it helps operators to maintain precise control over turbine operations, optimize performance, and minimize downtime. This makes it an invaluable asset in industrial settings where reliable and efficient turbine management is essential for continuous and productive operations.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | IS200TSVCH1AED |

| Manufacturer | GE |

| Product Type | Terminal Board |

| Electrical Input Voltage | [Specify voltage range] |

| Communication Protocol | Fibre – optic based protocol for data transfer |

| Physical Dimensions (L x W x H) | [Provide specific measurements in mm] |

| Interface Type | Multiple interfaces for system connectivity |

| Operating Temperature Range | [Specify temperature range in °C] |

| Humidity Tolerance | [Specify humidity range] |

| Data Transmission Rate | [Specify rate in Mbps] |

| Storage Temperature Range | [Specify temperature range in °C] |

IS200TSVCH1AED

Main Features and Advantages

Reliable data handling: The GE IS200TSVCH1AED is designed with advanced data handling mechanisms. It automatically writes data and relevant information to the send FIFO when data is being written to SDRAM. This ensures that data is transferred in an organized and efficient manner, reducing the risk of data loss or corruption during transmission.

User – configurable indicators: The terminal board features user – definable status LEDs. Operators can easily configure the on – board indicators by writing to the 31st bit of the control and status register. This flexibility allows for customization based on specific operational requirements, enabling better monitoring and control of the system.

Signal detection capabilities: With its signal detection LED, the GE IS200TSVCH1AED provides a simple yet effective way to check the functionality of the optical network. Additionally, its ability to detect if its own data is returned over the network (although defaulted to off) adds an extra layer of reliability, helping to quickly identify any network – related issues and ensuring smooth data flow.

Application Field

The GE IS200TSVCH1AED finds extensive application in the power generation industry, especially in plants that utilize gas and steam turbines. In these facilities, accurate and reliable data transmission is critical for the efficient operation of turbines. The terminal board enables seamless communication between various control components of the Speedtronic Mark VI system, allowing operators to monitor and adjust turbine performance in real – time.

It is also applicable in industrial manufacturing settings where steam turbines are used for power – intensive processes. Here, the GE IS200TSVCH1AED helps in maintaining the stability of turbine operations, ensuring consistent power supply for manufacturing equipment. By facilitating precise data transfer and monitoring, it contributes to reducing production downtime, improving overall productivity, and enhancing the safety and reliability of industrial operations.

IS200TSVCH1AED

Related Products

- GE IS200TSVCH2A: A related model that may offer enhanced features or additional functionality compared to GE IS200TSVCH1AED, potentially providing more advanced data processing capabilities.

- GE IS200TSVCH3A: This model could be designed for specific application scenarios, offering specialized interfaces or communication protocols to meet unique system requirements.

- GE IS200TSVCH4A: An upgraded version that might feature improved performance in terms of data transmission speed and reliability, making it suitable for more demanding industrial applications.

- GE IS200TSVCH5A: It could be a variant with different physical dimensions or installation requirements, providing more flexibility in system integration.

- GE IS200TSVCH6A: A related product that may focus on enhanced compatibility with other GE automation products, expanding the overall capabilities of the system.

Installation and Maintenance

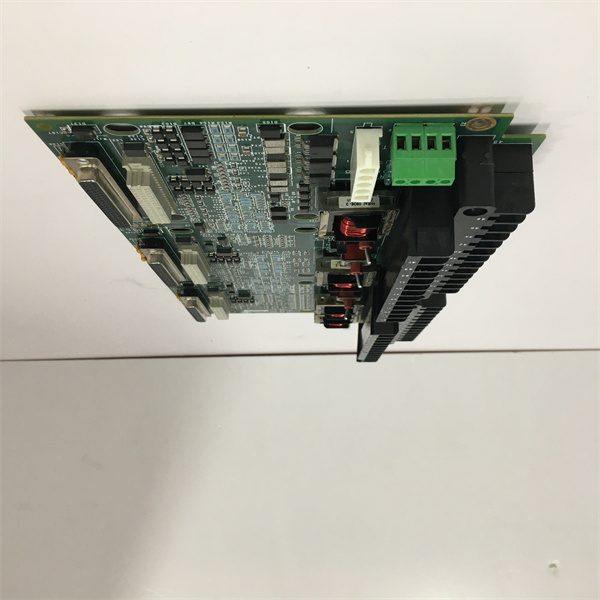

Pre – installation preparation: Before installing the GE IS200TSVCH1AED, ensure that the installation environment is clean and free from dust and debris. Verify the electrical specifications of the installation site to match the requirements of the terminal board. Check all the necessary connections and interfaces for any signs of damage. Also, ensure that the system is powered off during the installation process to prevent any electrical hazards.

Maintenance recommendations: Regularly inspect the GE IS200TSVCH1AED for any physical damage or signs of wear. Clean the board using an appropriate static – free cleaning solution to remove dust and dirt. Periodically check the signal detection LEDs to ensure that the optical network is functioning properly. If any issues are detected, refer to the product manual for troubleshooting steps. Additionally, keep the installation environment within the specified temperature and humidity ranges to ensure optimal performance of the terminal board.

Product Guarantee

We stand behind the quality of the GE IS200TSVCH1AED with a comprehensive product guarantee. Our quality assurance processes ensure that each terminal board meets the highest industry standards. In the unlikely event of a product defect, we offer a hassle – free replacement service. Our dedicated technical support team is available to assist customers with any installation, operation, or maintenance queries. We are committed to providing continuous support throughout the product’s lifecycle, ensuring that our customers can rely on the GE IS200TSVCH1AED for their industrial automation needs with complete confidence.