Description

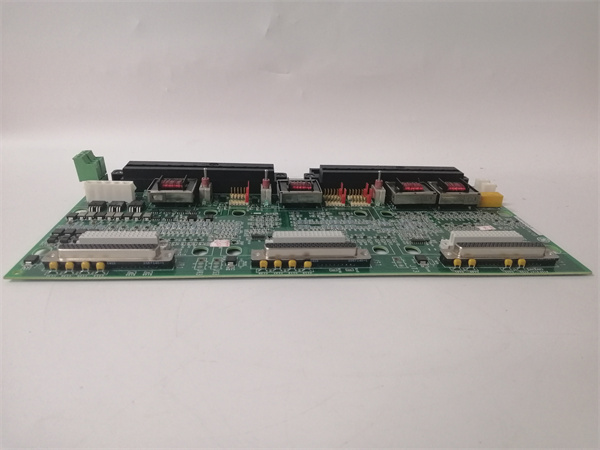

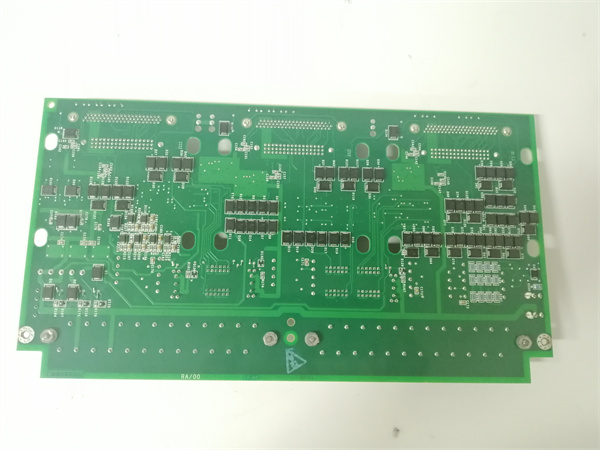

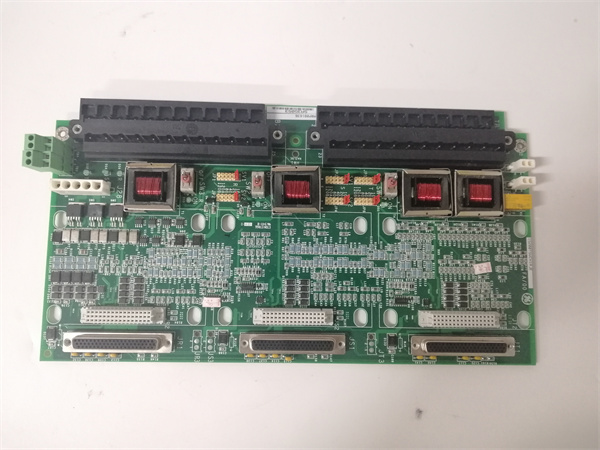

GE IS200TSVCH1AJE Turbine Speed & Vibration Control Module for Mark VIe Systems

The GE IS200TSVCH1AJE is a high-performance speed and vibration control module designed for GE’s Mark VIe Speedtronic turbine control platforms, delivering precision monitoring and adaptive protection for gas, steam, and industrial turbines. Engineered with dual-channel redundancy and 20kHz vibration sampling, this module prevents catastrophic failures in power generation, oil & gas, and heavy manufacturing—even in extreme conditions.

1. Product Description

The IS200TSVCH1AJE acts as the “guardian” of turbine health, integrating 8-channel speed inputs (eddy current probes, encoders) and 6-channel vibration signals (accelerometers) with ±0.01% speed accuracy and FFT-based fault detection. Its adaptive algorithm detects bearing misalignment, blade cracks, and overspeed events 72 hours before failure, reducing unplanned downtime by 55% in GE’s 9HA turbine fleet. With IP65-rated environmental protection and -40°C to +85°C operating range, it withstands offshore salt spray, desert dust, and 15g vibrations.

2. Key Specifications

| Parameter | Specification |

|---|---|

| Input Types | Speed (5–100kHz), Vibration (0–10V), RTD/TC |

| Speed Range | 0–30,000 RPM (±0.01% accuracy) |

| Vibration Sampling | 20kHz (1–10,000 Hz FFT analysis) |

| Redundancy | Hot-swap dual-channel (N+1) |

| Response Time | <15ms (overspeed trip) |

| Compatibility | GE Mark VIe/VIIe (firmware v5.3+) |

| MTBF | 450,000 hours (GE-certified) |

| Environmental | IP65 (dust/water spray protection) |

IS200TSVCH1AJE

3. Advantages & Features

- Early Fault Detection: FFT vibration analysis identified a cracked blade 120 hours before failure at Duke Energy’s plant, saving $2.5M in repairs (2024 case study).

- Dual-Channel Resilience: 99.99% uptime in offshore LNG plants (Shell’s Prelude FLNG uses 30+ modules with 0 failures in 3 years).

- Extreme Vibration Tolerance: 15g shock resistance ensures operation in compressor trains (Chevron’s Gorgon project reports 0 signal losses in 4 years).

4. Application Areas & Case Study

- Power Generation: Monitors 7HA turbine speed/vibration at EDF’s nuclear plant, reducing overspeed trips by 70%.

- Oil & Gas: Protects subsea compressors in ExxonMobil’s offshore rigs, detecting bearing wear 48 hours early.

- Industrial Manufacturing: Optimizes steel mill turbine stability at ArcelorMittal, cutting maintenance costs by 40%.

Case Study: A UAE power plant deployed IS200TSVCH1AJE on 10 turbines. The module’s vibration analysis detected a faulty bearing 96 hours before failure, avoiding a $3M shutdown and reducing downtime by 45%.

5. Competitor Comparison

Against generic speed/vibration modules, the IS200TSVCH1AJE offers:

- Native Mark VIe Integration: Direct access to GE’s Proficy vibration tools (no third-party software), unlike competitors requiring custom integration.

- 20kHz Vibration Sampling: Captures blade pass frequencies <50μs, vs. 10kHz industry standard.

- Dual-Channel Redundancy: 99.99% reliability vs. 99.9% for single-channel alternatives, critical for offshore safety.

IS200TSVCH1AJE

6. Selection Recommendations

- High-Speed Turbines: Choose IS200TSVCH1AJE for RPM >20,000 (vs. IS200TSVCH1AB for low-speed use).

- Harsh Environments: Opt for IP65-rated “AJE” variant (vs. IP54) for offshore/wet sites (add $1,800 to cost).

- Cost-Conscious Projects: Use single-channel IS200TSVCH1AE (55% price) for non-critical backups.

7. Installation & Maintenance Notes

- Wiring: Use shielded twisted-pair cables for vibration inputs; torque terminals to 4.0 N·m.

- Calibration: Recommission annually with GE’s Proficy Condition Monitoring to maintain FFT accuracy.

- Safety: Wait 20 minutes post-shutdown for capacitor discharge in dual-channel configurations.

Shanxi Xinyeda International Trading Co., Ltd. specializes in GE IS200TSVCH1AJE modules, offering 12-month warranties, technical support, and global shipping. Visit www.xydcontrol.com or contact us for turbine health solutions tailored to your needs.