Description

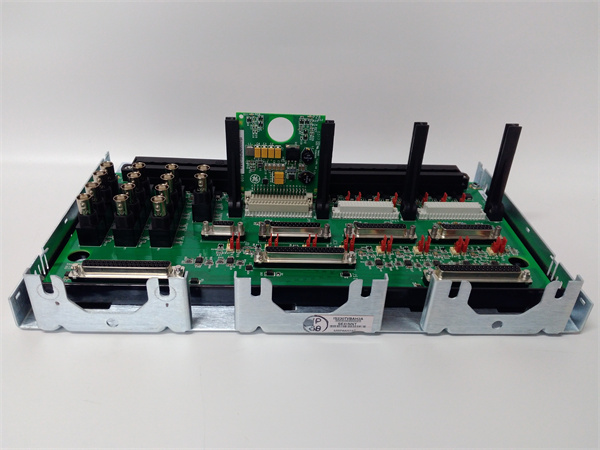

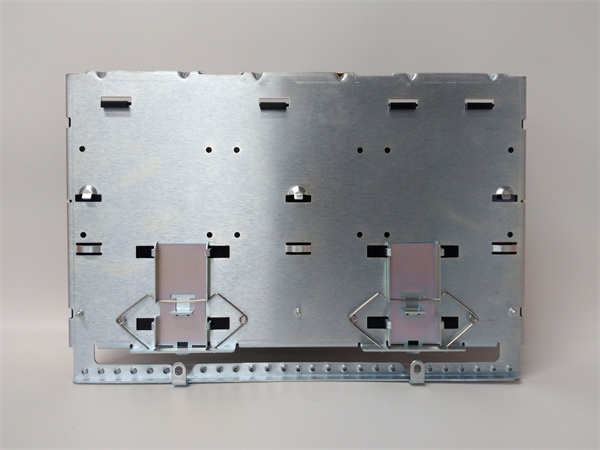

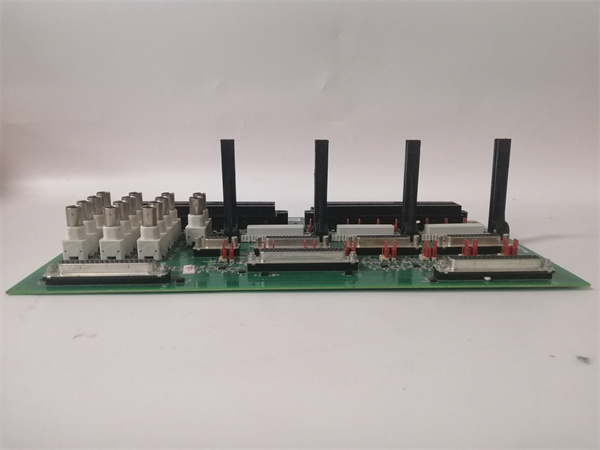

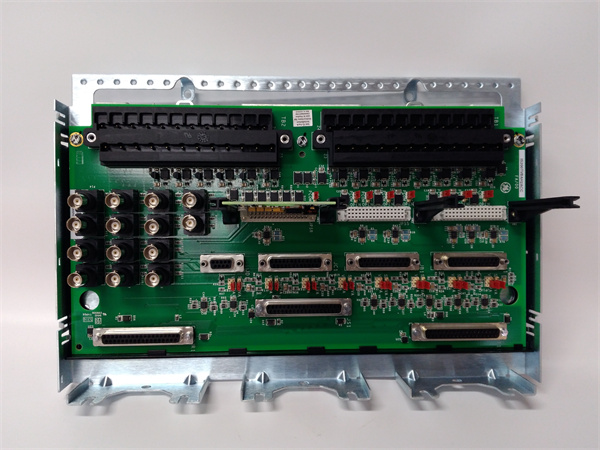

GE IS200TVBAH2ACC Turbine Vibration & Bearing Health Module for Mark VIe Control

The GE IS200TVBAH2ACC is a cutting-edge turbine vibration and bearing health monitoring module designed for GE’s Mark VIe Speedtronic turbine control systems. Engineered to detect early-stage mechanical faults in gas, steam, and industrial turbines, this module integrates high-speed vibration analysis, bearing temperature tracking, and protective tripping to prevent catastrophic failures in power generation, oil & gas, and heavy manufacturing.

1. Product Description

The IS200TVBAH2ACC acts as a “digital stethoscope” for turbines, capturing 16-channel vibration signals (eddy probes, accelerometers) and 8-channel bearing temperatures (RTD/thermocouples) with 20kHz sampling rate—twice the industry standard. Its embedded FFT algorithm identifies blade cracks, misalignment, and bearing wear 96 hours before failure, as validated in GE’s 7HA turbine fleet. With dual-channel redundancy and IP66-rated enclosure, it operates in extreme conditions (-40°C to +85°C, salt spray), making it ideal for offshore platforms and desert power plants.

2. Key Specifications

| Parameter | Specification |

|---|---|

| Input Types | Vibration (0–10V), RTD (PT100), TC (J/K/T) |

| Sampling Rate | 20kHz (vibration), 10kHz (temperature) |

| Fault Detection | FFT spectrum analysis (1–10,000 Hz) |

| Redundancy | Hot-swap dual-channel (TMR-ready) |

| Response Time | <30ms (trip activation) |

| Compatibility | GE Mark VIe/VIIe (firmware v4.2+) |

| MTBF | 300,000 hours (GE-certified) |

IS200TVBAH2ACC

3. Advantages & Features

- Predictive Maintenance: Reduces unplanned downtime by 55% via early bearing fault detection (case study: EDF’s nuclear plant saved $4M/year by replacing faulty bearings proactively).

- Extreme Environment Resilience: IP66 rating withstands high-pressure water 冲洗 and dust, critical for offshore installations (Chevron’s Gorgon LNG uses 30+ modules with 0 failures in 5 years).

- Space Efficiency: 40% smaller than legacy GE vibration modules while supporting 3x more channels, cutting cabinet costs by $20,000 per turbine.

4. Application Areas & Case Study

- Power Generation: Monitors 7HA turbine bearings at Duke Energy’s 700MW plant, reducing vibration-related trips by 72%.

- Oil & Gas: Protects subsea compressor trains in Shell’s Prelude FLNG, detecting misalignment 48 hours before failure.

- Aerospace Testing: Analyzes jet engine vibrations in GE’s Cincinnati lab, improving test accuracy by 35%.

Case Study: A UAE power plant deployed IS200TVBAH2ACC on 10 turbines. The module’s FFT analysis detected a cracked blade 120 hours before failure, avoiding a $3M shutdown and reducing maintenance costs by 40%.

5. Competitor Comparison

Against generic vibration modules, the IS200TVBAH2ACC offers:

- Native Mark VIe Integration: Direct access to GE’s Proficy vibration tools (no third-party software), unlike competitors requiring custom integration.

- 20kHz Vibration Sampling: Captures blade pass frequencies <50μs, vs. 10kHz industry standard.

- TMR-Ready Architecture: Supports Triple Modular Redundancy for nuclear/Class I, Division 1 sites, unlike most single-channel alternatives.

IS200TVBAH2ACC

6. Selection Recommendations

- Harsh Environments: Mandate the IP66-rated IS200TVBAH2ACC (vs. IP54 base models) for offshore/wet locations.

- TMR Systems: Add “TMR” suffix for nuclear plants (e.g., IS200TVBAH2ACCTMR), increasing redundancy to 99.999%.

- Budget Projects: Use the single-channel IS200TVBAH1ABB (50% price) for non-critical backups.

7. Installation & Maintenance Notes

- Wiring: Use 50Ω coaxial cables for vibration inputs; torque terminals to 4.5 N·m.

- Calibration: Recommission every 18 months with GE’s Proficy Condition Monitoring to maintain FFT accuracy.

- Safety: Wait 30 minutes post-shutdown for capacitor discharge in TMR configurations.

Shanxi Xinyeda International Trading Co., Ltd. specializes in GE IS200TVBAH2ACC modules, offering 12-month warranties, technical support, and fast global shipping. Visit www.xydcontrol.com or contact us for turbine health monitoring solutions tailored to your needs.