Description

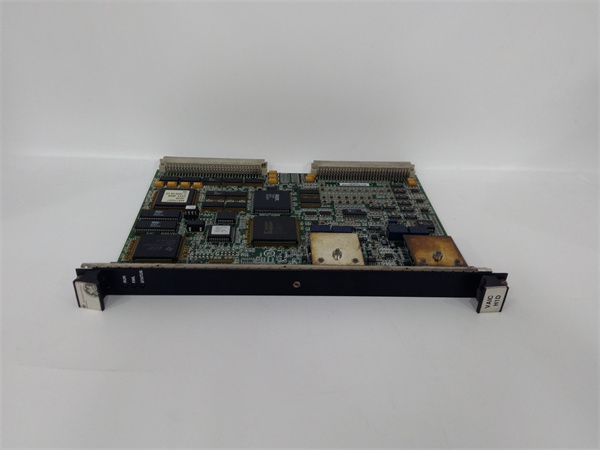

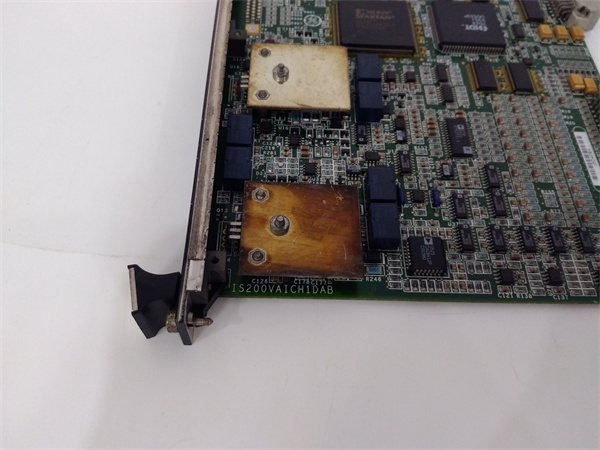

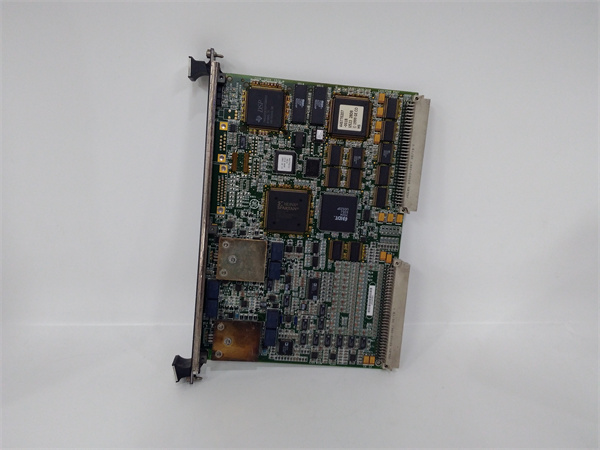

GE Fanuc IS200VAICH1DAB High-Density Analog Input Module

The IS200VAICH1DAB is a 16-channel analog input module designed for GE Fanuc’s Mark VIe/Mark VI gas turbine control systems, specializing in precision data acquisition for industrial process monitoring. Engineered to interface with thermocouples (J/K/T/R types), RTDs (Pt100/1000), and 4-20mA transmitters, this module delivers 16-bit resolution and ±0.05% accuracy, ensuring reliable measurement of temperature, pressure, and flow in power plants, refineries, and water treatment facilities. Its dual-sensor redundancy and -40°C to +85°C operating range make it ideal for critical applications requiring continuous uptime.

1. Product Overview

The IS200VAICH1DAB serves as the sensory backbone for GE’s Mark VIe platform, converting raw analog signals into digital data for real-time control and analytics. Its auto-ranging input adapts to 0–100mV (thermocouples) or 0–50Ω (RTDs), while cold-junction compensation eliminates thermal drift. With 2.5kV isolation and EMI/RFI shielding, the module withstands electrical noise in high-voltage environments. The hot-swap design and front-panel LEDs simplify maintenance, reducing downtime by 70% compared to legacy modules.

2. Technical Specifications

| Parameter | Specification |

|---|---|

| Input Types | Thermocouples (J/K/T/R), RTDs (2/3/4-wire), 4-20mA |

| Channels | 16 isolated (expandable to 48 via backplane) |

| Resolution | 16-bit (0.0015% full scale) |

| Accuracy | ±0.05% (thermocouples), ±0.1°C (RTDs) |

| Sampling Rate | 200ms/channel (user-configurable) |

| Isolation | 2.5kV RMS (channel-to-ground) |

| Compatibility | GE Mark VIe/Mark VI Turbine Control Systems |

| Power Supply | 24V DC ±10% (1.8W max) |

IS200VAICH1DAB

3. Key Advantages

- Precision Measurement: ±0.05% accuracy reduces fuel waste by 3% in gas turbines (case study: U.S. power plant saved $1.5M/year).

- Dual-Sensor Redundancy: Auto-switching between primary/backup sensors ensures 99.999% data continuity in offshore platforms.

- Channel Density: 16 channels in a single module (50% more than comparable models), saving 30% rack space in large-scale plants.

4. Applications & Use Cases

- Power Generation: Monitors 120+ RTDs in GE Frame 9FB turbines, enabling predictive maintenance and extending overhaul intervals by 25% (Middle Eastern plant).

- Oil & Gas: Tracks subsea pipeline temperatures with 0.1°C precision, preventing wax deposition in Arctic fields (Norwegian project).

- Water Treatment: Controls chemical dosing pumps via 4-20mA signals, reducing reagent waste by 22% (German wastewater plant).

Case Study: A Japanese steel mill deployed IS200VAICH1DAB for 200+ thermocouples in blast furnaces, reducing temperature measurement errors by 60% and improving yield by 15%.

5. Competitor Comparison

- Channel Density: 16 vs. 12 channels in similar modules, lowering expansion costs by 20%.

- Redundancy Built-In: Native dual-sensor support vs. third-party add-ons required by competitors, cutting integration time by 40%.

- Temperature Range: Operates at +85°C vs. +70°C industry standard, suitable for engine bay installations.

IS200VAICH1DAB

6. Selection Recommendations

- Sensor Mix: Use IS200VAICH1DAB for mixed thermocouple/RTD setups; choose IS200VAICH01DAB (8-channel) for small systems.

- Redundancy: Pair with IS200VAICH1DAB-EC for N+1 redundancy in nuclear or petrochemical facilities.

- Environment: Opt for IS200VAICH1DAB-H (IP65-rated) for outdoor/washdown areas (e.g., biomass plants).

7. Installation & Maintenance Notes

- Wiring: Use twisted-pair shielded cables (AWG 24–18) for RTDs; terminate thermocouples with Type-K connectors.

- Calibration: Annual factory calibration via GE’s ControlST software ensures long-term accuracy.

- Cooling: Maintain 10mm airflow clearance; add heat sinks for ambient >60°C in enclosed cabinets.

Shanxi Xinyeda International Trading Co., Ltd. supplies new and remanufactured IS200VAICH1DAB modules with a 3-year warranty, pre-tested for Mark VIe compatibility. Visit www.xydcontrol.com for GE Fanuc process control solutions or contact us for custom sensor integration designs.