Description

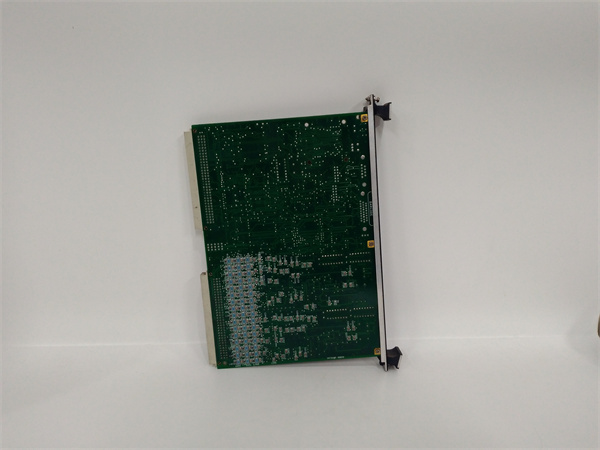

GE IS200VRTDH1D Product description

The GE IS200VRTDH1D is a versatile and scalable controller module designed to increase the number of analog input channels in a system to connect more sensors and capture more analog signals. The module usually communicates with the control system and transmits the acquired analog signal to the main control system. It needs to be configured and programmed to accommodate different sensor types, signal ranges, and application requirements.

Product parameter

Input voltage: 24 VDC

Output voltage: 0~10 VDC

Operating temperature range: -40℃ to +85℃

Size: 100mm×50mm×30mm

Weight: 200g

Communication interface: RS485

Protection function: overload protection, short circuit protection

Product specification

Input channels: 8

Sensor type: RTD (Pt100, Pt500, etc.)

Measuring range: -200°C~800°C

Measurement accuracy: ±0.1°C

Resolution: 0.01°C

Update time: 10ms

series

The GE IS200VRTDH1D belongs to GE’s Mark VI family of modules designed for industrial control systems to provide high precision and reliable temperature measurement.

trait

High precision: The temperature signal measured by the RTD sensor can be converted into a digital signal for computer acquisition, analysis and processing.

Versatility: Suitable for industrial automation, process control and monitoring systems.

Reliability: Industrial design, with high reliability and anti-interference ability.

Ease of use: Friendly configuration software is provided to facilitate user Settings.

Function and use

Temperature monitoring: used to monitor and control the temperature in industrial processes, such as reactor temperature, pipeline temperature, etc.

Device fault detection: By early detection of temperature anomalies, device faults can be detected and diagnosed in a timely manner.

Data acquisition: The collected analog signal is transmitted to the main control system for data processing and analysis.

Application field

Power plant: DCS monitoring system.

Oil and gas industry: Manufacturing of intelligent flat tempering furnace systems.

Manufacturing: PLC programmable transmission control system, DCS caustic control system.

Chemical industry: chemical liquid constant current computer control system.

Power industry: electrical control system, paper printing and dyeing production line substation integrated automation control series.