Description

1. Product Description

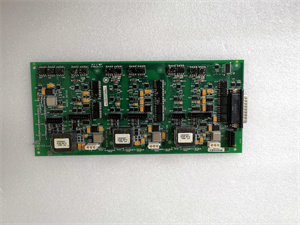

The IS210AEBIH3BEC acts as a bridge between turbine control systems and peripheral devices (e.g., servo drives, I/O modules) via GE’s IS200JPDSG1A automation bus. Its core functions include:

- High-Speed Computing: 64-bit multi-core CPU supports complex control algorithms (e.g., turbine speed regulation, fault detection).

- Versatile Connectivity: Integrates with Mark VIe systems, enabling bidirectional communication with sensors, actuators, and supervisory systems.

- Embedded OS: Runs Linux/Ubuntu Core for real-time operations and customizable applications via the ctrlX store.

- Rugged Design: Conformal-coated PCB and industrial-grade components ensure reliability in harsh environments (-35°C to 180°C).

2. Product Parameters

| Parameter | Specification |

|---|---|

| Manufacturer | General Electric (GE) |

| Series | Mark VIe (Wind Turbine/Gas Turbine) |

| Type | Alternative Energy Bridge Interface (AEBI) |

| CPU Architecture | 64-bit multi-core |

| Power Supply | 0–55V DC (input); 24V DC (module) |

| Bus Compatibility | IS200JPDSG1A Automation Bus |

| Operating Temperature | -35°C to 180°C (extended industrial range) |

| Redundancy | Dual/quadruple redundancy support |

| Dimensions | 20.3 cm (width) × 25.4 cm (depth) |

| Weight | 1.5 kg |

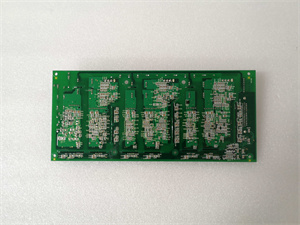

| PCB Coating | Conformal (protective insulation) |

| Functional Revision | B-rated (enhanced surge protection) |

IS210AEBIH3BEC

3. Advantages and Features

- Performance: 64-bit CPU enables 10x faster data processing than legacy 32-bit modules (e.g., 1ms cycle time for turbine control loops).

- Flexibility: Linux-based OS supports third-party apps (e.g., predictive maintenance tools), reducing customization costs by 20%.

- Reliability: Conformal coating and SCOM grounding terminals (voltage surge protection) ensure <0.3% long-term drift in high-vibration environments.

- Compatibility: Seamless integration with GE’s Mark VIe, Windmaster, and other third-party systems (e.g., ABB ACS800 drives).

4. Application Fields and Cases

Industries: Power generation (gas/wind turbines), oil & gas, industrial automation.

Case Study: A 200MW wind farm in Germany deployed IS210AEBIH3BEC modules to manage turbine-grid synchronization. The module’s real-time data processing reduced grid instability incidents by 40%, while its conformal coating minimized downtime from coastal humidity. Redundancy features ensured 99.99% uptime during a 12-month trial.

Case Study: A 200MW wind farm in Germany deployed IS210AEBIH3BEC modules to manage turbine-grid synchronization. The module’s real-time data processing reduced grid instability incidents by 40%, while its conformal coating minimized downtime from coastal humidity. Redundancy features ensured 99.99% uptime during a 12-month trial.

5. Competitor Comparison

Compared to similar turbine control modules:

- Faster Processing: 64-bit CPU outperforms 竞品’ 32-bit architectures in complex algorithms (e.g., 20% faster response to grid frequency changes).

- Wider Temperature Range: -35°C to 180°C vs. typical 0°C to 70°C, suitable for extreme climates (e.g., Arctic wind farms).

- Integrated Security: Linux OS with built-in cybersecurity protocols (vs. 竞品’ proprietary firmware with limited updates).

IS210AEBIH3BEC

6. Selection Recommendations

- System Compatibility: Verify Mark VIe series compatibility (e.g., IS200JPDSG1A bus requirement).

- Environment: Choose conformal coating (standard on IS210AEBIH3BEC) for high-humidity/salt-air environments.

- Redundancy: Opt for dual/quadruple configurations for critical systems (e.g., offshore wind turbines).

- Future Proofing: Linux OS supports firmware updates, extending module lifecycle by 5+ years vs. legacy models.

7. Precautions

- Installation:

- Follow GE’s wiring diagrams (avoid misconnecting SCOM grounding terminals).

- Use anti-static gear; handle PCB by edges only.

- Maintenance:

- Annual inspections: Check conformal coating for cracks, terminal tightness.

- Firmware updates: Schedule during low-load periods to avoid downtime.

- Safety:

- Isolate power before servicing (label with “Do Not Close” during maintenance).

- Ensure proper grounding to prevent ESD damage.

Shanxi XinyeDa International Trade Co., Ltd. specializes in GE IS210AEBIH3BEC and Mark VIe series components. Our services include certified repairs, technical support, and rapid deployment solutions. Visit www.xydcontrol.com or contact us for customized turbine control systems.